March 7, 2024

By Simer Virk, UGA Extension Precision Ag

It’s not hard to miss large fertilizer spreaders on the roads or in fields this time of the year, which means another crop season is officially here. Lime and fertilizer applications will be in full swing from now until planting.

These large self-propelled spinner-spreaders have become more common over the years for spreading lime and dry fertilizer applications. However, along with their big size and increased spread widths over traditional pull-behind spreaders, it is also not hard to miss the fast speeds they are operated at during fertilizer applications.

One question has come up consistently during some of the recent meetings with growers: “How accurate are the variable-rate applications when these spreaders are flying through the field?”

I have wondered about that myself but like anyone else knows that the correct answer is that fertilizer applications at these excessive speeds are not very accurate. Besides ground speed, the accuracy of variable-rate applications also depends on many factors, including spreader setup and operation, calibration, rate controller setup, material density, and few more.

But for now, let’s visit two main big considerations that can help in understanding and hopefully making some adjustments by operators for accurate variable-rate fertilizer applications as it relates to ground speed.

Rate transition time

While the variable-rate technology on modern agricultural machinery, including spinner-spreaders, has advanced considerably and is pretty responsive, but there is always some transition time for the rate change to happen. This transition time can vary from one spreader to another but can be reduced by adjusting the rate controller setup and valve sensitivity.

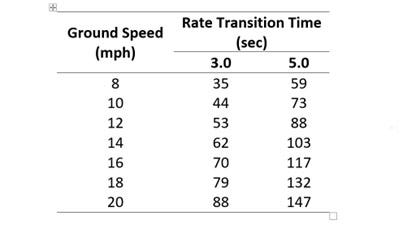

Generally, this time can be anywhere in the range of 3 seconds to 5 seconds depending on the setup and can thus affect how accurately different rates are attained during variable-rate applications. As an example, the table below shows distance needed by the spreader to make the rate transitions based on different ground speeds and transition time of 3 and 5 seconds.

We can notice that this distance increases linearly with ground speed and rate transition time. As for ground speed only, it means the faster the spreader, the longer the distance it is going to take to make those rate transitions.

The main thing to note here is spreaders running at speeds above 15 mph are going to need at least 70-foot of distance to make the rate change. If there are areas smaller than that within the field with different rates, most likely they will not receive the target fertilizer rate, overall resulting in a poor application. Slowing down does help in better and more accurate fertilizer applications.

Prescription map

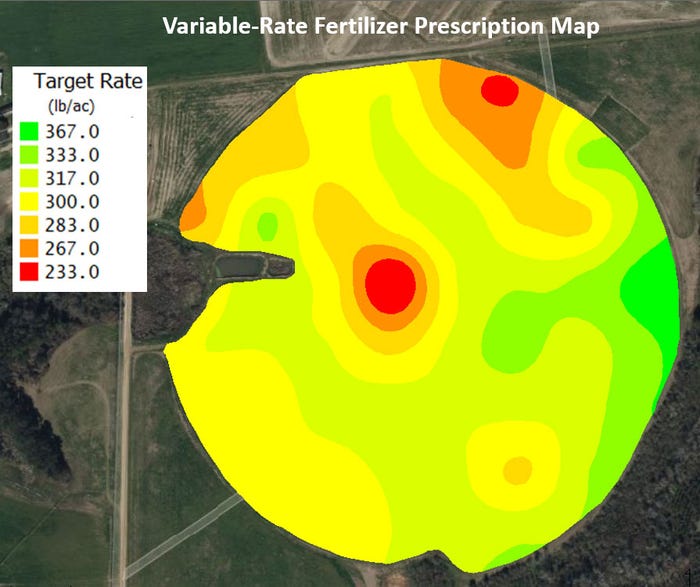

Besides ground speed, the accuracy of variable-rate applications can also be improved by making appropriate adjustments to the prescription map while generating it and before uploading it to the spreader controller. One of the common issues with most variable-rate prescription maps is too many rates, especially in several smaller areas within the field, like the map below.

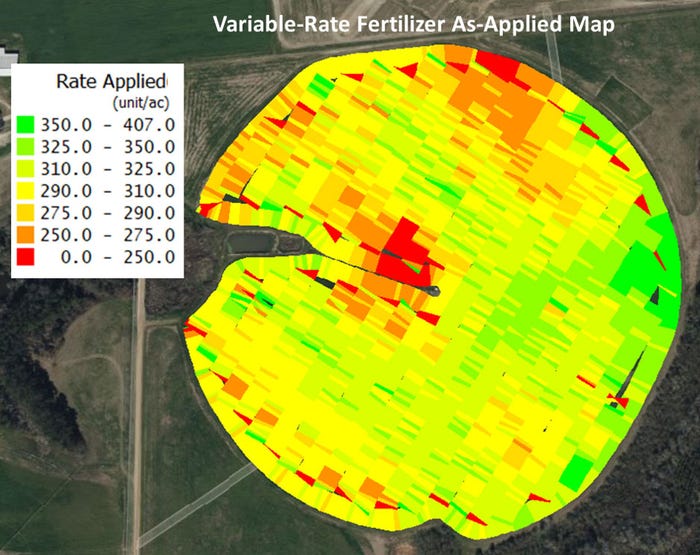

In this case, the spreader would be continuously chasing different rates without maintaining a target rate for a longer period of time, which would again result in poor application and something that will resemble the as-applied map shown below. Faster ground speed would further degrade the application quality in this case.

This issue can be resolved by combining smaller areas with adjacent application zones and prescribing a single application rate accordingly for smoother transitions and overall an effective application.

You May Also Like