August 19, 2022

Sponsored Content

Poor spray quality is one of the largest causes of chemical-resistant weeds, weed escapes, chemical wastage, and yield loss. Unfortunately, it’s nearly impossible to see spray quality issues with the naked eye. As a result, farmers could have partially blocked nozzles they don’t know about until it’s too late because they’re not monitoring every nozzle for pressure, flow and droplet size.

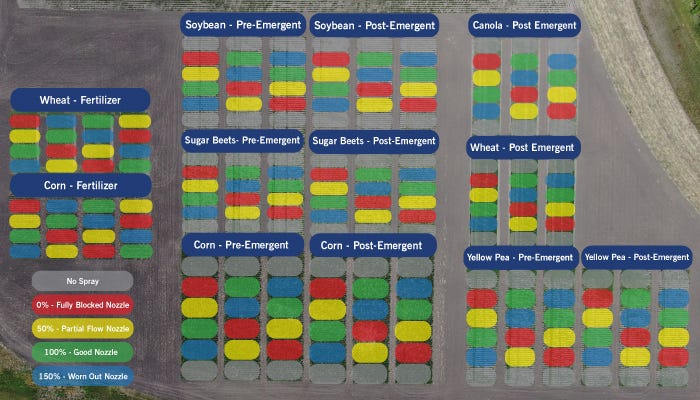

Intelligent Ag™, a leader of innovative agricultural technologies, wanted to determine the impact of various spray nozzle problems during operation that can affect a farmer’s yield. They conducted the “Spray Quality Study” to measure the effectiveness of herbicides when applied at various rates by one nozzle to determine if a single nozzle can impact spray accuracy.

The tests were conducted in 144 different plots with four separate individual nozzle misapplication types utilizing common herbicides and liquid fertilizer. The study included 3 iterations of each nozzle variation across 6 different crop types and demonstrated three important aspects associated with spray accuracy.

Key takeaways from study:

Partially blocked nozzles can lead to weed escapes due to underapplication, even with overlap from the neighboring nozzles.

Completely blocked nozzles resulted in a lack of coverage in the area, creating weed escapes and chemical resistance.

Overapplication from a single nozzle can result in stunted crop growth.

“As fungicides and insecticides become more sophisticated, droplet size becomes a more complex issue for chemical effectiveness. As a result, farmers require real-time analysis of each individual nozzle pressure, flow, and droplet size to improve spray quality,” said Calby Beckstrand, Product Manager at Intelligent Ag.

Accurate spraying is complicated, but it doesn’t have to be. Recon SpraySense™ is the industry’s first real-time spray monitoring system designed to give farmers a nozzle-by-nozzle analysis of flow rate, pressure and droplet size to improve spray quality and accuracy.

Click here to learn more about how Recon SpraySense™ can help you prevent weed escapes, wasted chemicals, reapplications and yield loss.

This demonstration shows real-life examples of various nozzle flow problems. Nozzle issues are incredibly difficult to see (especially from the cab). By the time you can actually see a problem, it’s usually much worse than you think. Visual inspections are just not good enough. What appears to be flowing properly often times is not. Drift reducing nozzles are even more difficult to see flow problems.

About the Author(s)

You May Also Like