October 14, 2015

Fleet management, a concept used in trucking for years, has found a place on Midwest crop farms. It used to be that all you’d need on a 1,000-acre farm was a few tractors, a combine, a semi for hauling grain and maybe a self-propelled sprayer, making it fairly easy to manage logistics.

But now, as farm operations are pushing 5,000 acres or more, suddenly you might have a machinery lineup that is two or three times that size, making concepts such as logistics management and equipment utilization a necessary science.

Luckily, the technology is there to help you do those things remotely. Most of the new commercial-size farm vehicles coming out of factories today are equipped with onboard telematics systems that give you a live view of what is going on with your equipment, and let you collect and manage the information.

You can monitor vehicle location, operating status, fuel levels, maintenance schedules, fault codes and a host of other parameters, all from your iPhone, iPad or laptop computer. The end goal with these telematics systems is to maximize the use of your machinery and lower operational costs through better fleet performance.

As with any new technology, unless you use it all the time, you might not be aware of all its functions and features. So we went straight to product reps from major original equipment manufacturers and asked them to give us a rundown of what these telematics packages can do — everything from tracking to two-way file transfer. So get ready to be “remoted in.”

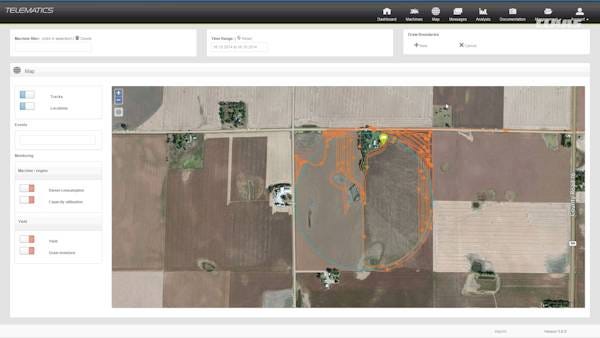

Claas Efficient Agriculture Systems tracking feature

Tracking and logistics

Fleet management requires tracking your equipment, and the latest telematics packages have made it easy to do that. Each vehicle with a GPS chip appears as a moving icon on a computerized map that is time-stamped with its georeferenced location.

Seeing vehicles on a map in real time lets you better manage the logistics of who goes where and when. You can monitor field progress, clear up bottlenecks, dispatch another machine, manage coordinating vehicles at planting and harvest, or find a machine that is broken down.

The screen shot shown below is part of Claas’ Efficient Agriculture Systems (EASY). Machines appear on a live map used for tracking and logistics. You can see the location of the combine, represented by the green icon toward the top right. The orange lines show areas of the field that have been harvested.

The tracking feature also keeps a record of where the vehicles have been, a feature called “breadcrumbing.” This is useful to see how much of a field is planted or harvested. It also serves as documentation if you need to look back and see where a machine was on a particular day.

Alerts offer real-time help

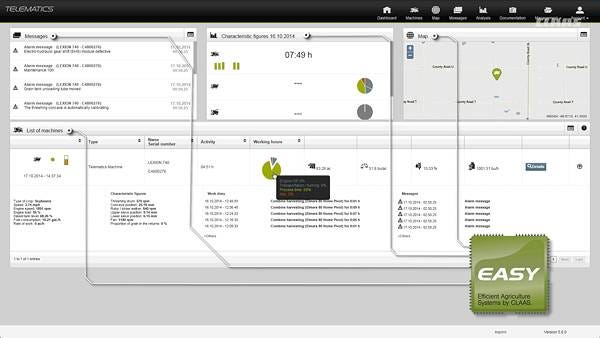

Claas Easy System telematics alerts screen

Telematics packages also have preset alerts, or ones that you can set yourself, that will notify you if something goes wrong or is operating outside of a certain parameter. The notifications are sent via text or email. One parameter you could set is a field boundary, and if a vehicle goes beyond that boundary, you would be notified. Other parameters might be speed, idle time, engine temp, fuel level, error codes or maintenance scheduling.

One example cited by the companies is an alert tied to speed at planting. The target speed could be set for 5 to 6 mph, and if the driver exceeds that speed, the operator would be notified, so that he or she could then contact the driver to slow down.

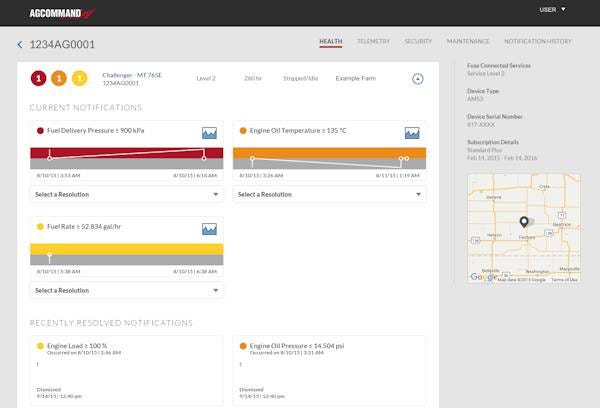

The Agco example screen shown above right, part of Agco’s AgCommand telematics system, has three alerts; two are tied to fuel levels and a third is tied to the engine oil temperature. In this example, fuel rate or delivery pressure that is higher than the norm would trigger an alert. Another alert would be sent if the engine oil temperature exceeded 135 degrees C.

The screen shot directly above, this one by Claas’ Easy System, shows some of the alerts that could be set for combines. The sample alerts shown here point to error codes with an electro-hydraulic gear shift module, grain tank unloading tube, potential malfunctioning with the combine unloading tube and a reminder for scheduled maintenance. The ability to identify these things ahead of time saves downtime in the field.

Agco Ag Command custom alerts

Machine monitoring helps track performance

Tracking a machine is one thing, but you also can look inside the machine to see how it is operating through a machine monitoring feature. You can pull up a dashboard view of basic functions, such as oil temperature, fuel level, battery life, engine rpm, speed and tire pressure, as shown below on the Case IH AFS Connect dashboard.

For a detailed look, you can pull up information from a vehicle’s controller area network or CANbus, which is an onboard computer network that collects everything there is to know about a tractor’s functions. Information that runs across the CAN can be viewed onscreen. For example, Agco’s Ag Command lets you view all of your machines from one screen. Each row shows the make and model of machine, the level of service, hours worked, status and if any alerts have been flagged. All of this information is pulled off the controller area network, or CAN, that is part of each vehicle. CAN viewers also can show the fan speed, gear engaged, rear PTO speed, hydraulic oil pressure, autosteering status, battery voltage and information about the engine, such as boost pressure, engine speed, coolant temperature and oil pressure. On a combine, those parameters could include yield levels, moisture, sieve settings and rotor speed, as shown on the screen above from New Holland’s PLM Connect.

So how could this information be used? Chris Carrier, New Holland’s PLM and T7 tractor manager, gives an example where you might have multiple combines harvesting. “A farm manager has three combines harvesting this fall, but notices that one of the combines is harvesting less grain than the other combines,” Carrier says. “The farm manager, or experienced operator, can remotely view the combine’s settings in real time and compare with the other two combines. The farm manager, or experienced operator, can then message the underperforming combine operator to adjust settings, so that losses are minimized and all three combines are operating at peak performance.”

Case IH AFS Connect dashboard.

Implements join the telematics movement

Farm implements have their own computer networks, or CANBUS, onboard, so you can tap into their systems as well to get a live stream of information. Not all telematics packages offer this yet. This year, though, John Deere introduced a telematics product called SeedStar Mobile that collects and monitors up to nine layers of information on a planter including population, singulation, seed spacing, downforce, variety and ground speed on a row-by-row basis. All of the information appears on a high-definition map, as shown above. This information can be used to fine-tune planter settings or diagnose problems with the planter. This year John Deere introduced a similar product for combines called Harvest Mobile that lets you live-stream and monitor layers of information about your combine.

John Deere SeedStar mobile

Remote diagnostics can keep you rolling

New Holland iPad PLM Connect CAN viewer

Part of keeping a fleet up and running is the ability to diagnose a problem. The old way of doing that was to call your dealer, who would then drive out to the field, hook up instrumentation that would identify fault codes, and then drive back to the dealership to get the necessary part. Telematics packages allow dealers to view those codes or machine settings remotely, so they can be equipped with the right tools or parts the first time.

Leo Bose, Advanced Farming Systems (AFS) marketing manager, says a dealer using the Case AFS Connect system can click on the “Reports” tab to get a live view of CANBUS parameters’ values to trouble-shoot an engine issue. “Under the Reports tab, the dealer can view battery voltage, diesel exhaust fluid [urea] level, engine boost pressure, engine coolant temp, engine fuel rate, engine hours, engine load, engine oil pressure and engine oil temperature,” Bose says. “The dealer can view the values of CANBUS parameters to see, for example, if the boost pressure is within the correct range. If not, I can look at other parameters that have a correlation and decide what tools or parts my service technician needs before he leaves.”

Most telematics packages from OEMs have this feature, whereby dealers, with your permission, can remotely access your machine’s diagnostics system. Dealers can also use it to identify maintenance items, such as worn air filters, and schedule a replacement before it becomes a problem.

Reports offer post-event analysis

Agco Ag Command

The data that is collected over the CAN can be organized in reports that measure the productivity of each machine.

There are many different reports that can be generated from this data, depending on what you need. Carrier of New Holland says one report available is Equipment Utilization, which enables farm managers to run reports that show how the equipment is being used during a specified period of time.

The report calculates percentages for idle time, traveling time, percent working, high workload, unload times and other productivity parameters. “Farm managers can customize the report settings so that the system generates reports based on the parameters they need for making decisions,” Carrier says. “They may also compare this data with other reports, such as productivity by machine or operator, fuel usage reports, and track historical locations of the machines. The farm manager can analyze this data for gaining insights that help them better optimize their fleet’s size and productivity.”

New Holland PLM Connect Equipment Utilization report.

2-way file transfer boosts efficiency

Finally, when you use telematics for fleet management, you also are buying a way to transfer data using the same wireless connection. Otherwise, you would have to use a USB stick to transfer the data — a manual process that involves lag time and the risk of losing the USB stick.

Up until recently, the data transfer was one-way, meaning data flowed from the vehicle to your office computer. But new communications technology now makes it possible to send and receive data files between the office and field. The major OEMs announced products this year that have this capability. Examples include John Deere’s JDLink Connect, Case IH’s two-way file transfer, New Holland’s PLM Connect and Agco’s Go-Task app. Aftermarket companies have offered this capability for a few years now. Examples include Raven’s Slingshot and Trimble Connected Farm. Data files that can be sent back and forth without a USB flash drive include guidance lines, yield data, variable-rate application maps and coverage maps.

The key phrase here is API, or application program interface, and it is bringing a whole new level of decision support services to farmers, because machinery companies can use their telematics link to facilitate file sharing on the same online platform or “cloud.”

Case IH AFS Connect remote diagnostics

A few key points to remember

What follows is a quick list of new features, a buyer's checklist and other information that helps add value to telematics for your farm:

New features for 2016

The technology to manage fleets has really ramped up this year. Equipment manufacturers have announced these new features as part of their telematics packages for 2016:

* high-definition streaming

* two-way file transfer

* Application Programming Interface (API) for software-to-software communication

* remote implement monitoring

* improved connectivity and cellular network coverage

Buyer's checklist

Many of the new farm vehicles sold have telematics systems. Older equipment will require an add-on device or dongle to get the same wireless transferability.

Either way, telematics systems are made up of the same basic components. Here’s what you’ll need onboard:

* modem or Wi-Fi device

* GPS antenna/receiver

* subscription service

* display interface

How dealers are using telematics

Collecting error codes will lead to better equipment in the future.

Telematics systems that help farmers manage fleets also are helping equipment companies design better equipment. The error codes and performance data captured by these systems are being compiled into a database that manufacturers can use to identify issues that are occurring within a population of machines. Those issues can then be addressed in future generations of equipment to improve uptime and pre-empt breakdowns.

The use of big data and advanced analytics is giving way to a whole new science called “vehicle uptime” or “managed downtime.” These new software systems sift through lines of fault codes collected over a vehicle’s lifetime, uncovering performance patterns that can predict when a machine or part is about to fail. The dealer can then address the problem before the owner-operator even knows it is there.

About the Author(s)

You May Also Like