March 4, 2020

Prior to spring field operations, making sure your equipment is ready can save valuable time and reduce stress when time gets tight due to weather conditions. The sprayer is a critical piece of equipment used for crop production. “Ensuring your sprayer is mechanically sound, clean and properly set up will help ensure quality and timely applications of spring fertilizer and pesticides,” says Ryan Bergman, Iowa State University program coordinator in ag technology.

Bergman is part of a 20-person ISU research team focusing on precision ag, big data, telematics, data analytics, aerial imagery and ag machinery automation. He provides the following information on sprayer maintenance.

Nozzle selection and setup

Spray nozzles are a critical piece of spray applications. Take time to look at the herbicides and other products you plan to apply in 2020, and evaluate if the nozzles you already have will work well with those products at the speeds and pressure you plan to use. Some chemicals, like dicamba and 2,4-D products, have strict nozzle requirements, whereas other products like glyphosate allow more choices.

For example, there are only four types of TeeJet nozzles approved for use with Enlist Duo herbicide (see nozzle specifications on the herbicide label). What if you are applying a tankmix of herbicides? When applying multiple products, refer to the label of the product with the most strict nozzle requirements to select your nozzle for that application.

Speed is also a consideration. If you operate at a wide range of speeds and pressures during the season, you may want to evaluate the benefits of a PWM (pulse-width-modulated) spray system to provide a broader range of nozzle flow rates while managing droplet size more consistently.

Running the sprayer with water to evaluate nozzle performance before the season starts is a best practice. Ensure this is done in a safe manner with proper personal protective equipment; it allows you to check the flow through each nozzle. While this can be time-consuming, it helps you identify worn, plugged or damaged nozzles. Using a tool like a SpotOn Sprayer Calibrator (a video is available) can make this process quicker and simpler.

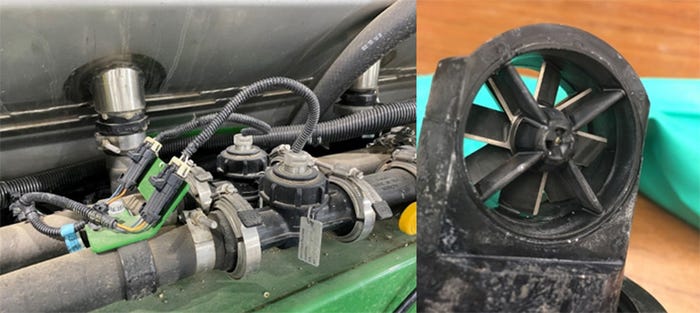

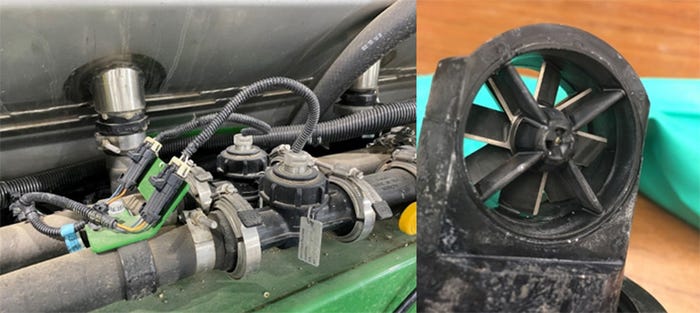

Nozzles with debris buildup (see the photo below) can cause significant deviations in flow between nozzles on a common rail-boom setup. The debris will cause the affected nozzle to experience a different pressure than nonplugged nozzles on another area of the boom, and it will create rate variation across the boom. This illustrates the importance of recognizing the quality of water you are spraying, and taking appropriate measures to protect your system from debris. This might include additional strainers on the loading lines of the machine and cleaning nozzles more frequently.

It’s also good to examine nozzle alignment during this process. Nozzle holders or mounts can bend or move (especially if booms frequently hit the ground or other obstructions). Proper alignment ensures the optimum spray pattern is maintained by your machine.

DIRTY STRAINERS: Debris often builds up on nozzle strainers as a result of dirty water, dirty carrier solution or chemical buildup. If left clogged, the clog will restrict solution flow through the nozzle and impact the application rate for this nozzle.

Check the plumbing system

It’s always recommended that the sprayer’s plumbing system is cleaned regularly to avoid chemical buildup and potential cross contamination. Double-check these areas prior to heading to the field in 2020.

• Strainers are crucial to ensuring particulate doesn’t get into the solution system or nozzles. Regular cleaning of all strainers on the machine is always recommended. Some machines have multiple strainers on the chassis or boom.

• Inspect the machine plumbing for hoses that aren’t properly secured, are sagging or have excess wear. Sagging or kinked hoses can impede solution flow and cause chemicals to become trapped in these areas. Replace worn hoses and tie up loose hoses.

• Remove and check the end caps on solution tubes for buildup, and clean if needed.

• Depending on the type of flowmeter your system uses, remove the insert and ensure it’s clean and can move freely.

• Have the flowmeter on your machine recalibrated. Your local equipment dealer or rate-control supplier can assist you with this process.

• The fencerow nozzles (on the end of the spray boom) are typically the first to be broken on a machine due to their placement. If your machine is equipped with them, make sure the nozzles and plumbing are in good working order and the system is functional if you intend to use it.

• Check around fittings for any chemical residue or evidence of leaks.

• Inspect the foam marking systems if equipped. While many operators don’t use these today, they can come in handy if your machine experiences GPS problems.

CLEAN OFTEN: Frequently inspecting and cleaning the main solution strainer will reduce pressure drop in the system, improve the consistency of the spray application rate and the life of spray system pumps, and reduce risk of contamination when switching products.

General machine maintenance

It’s important to make sure your sprayer is mechanically sound. Consult your owner’s manual for checklists and specifications to evaluate during this process. Make sure parts and joints are properly lubricated with grease or oil. Also, be sure machine fluids are at the proper level, filters are clean and in good condition, and tire mounting nuts are properly torqued and in good condition. Many boom suspension components require frequent lubrication to ensure adequate movement and can have an impact on boom height-control performance.

FLOWMETER: Routine cleaning of the sprayer’s flowmeter will ensure accurate application rates and reduce the calibration requirements for the solution system.

Sprayer tires also are important to evaluate and check. Due to the high speeds and axle loads they experience, these tires need to be in good operating condition and properly inflated.

“Taking time to inspect and maintain your sprayer now is one step to preparing for a smooth spring,” Bergman says.

Source: ISU, which is solely responsible for the information provided and is wholly owned by the source. Informa Business Media and all of its subsidiaries are not responsible for any of the content contained in this information asset.

You May Also Like