August 27, 2010

When burley tobacco first began to be grown in areas of North Carolina and Virginia where it had not traditionally been produced, it was thought the new farmers would not want to harvest using the traditional labor-intensive method.

That method revolves around cutting the burley plant close to the ground, spearing them on a stick, then hanging the loaded stick in the barn to cure in the air.

It’s a lot of work, and one university researcher predicted flatly, “If burley is going to come to eastern North Carolina (the Piedmont and Coastal Plain), it cannot be put on a stick. People aren’t going to work like that.”

Several different types of harvest mechanization were proposed.

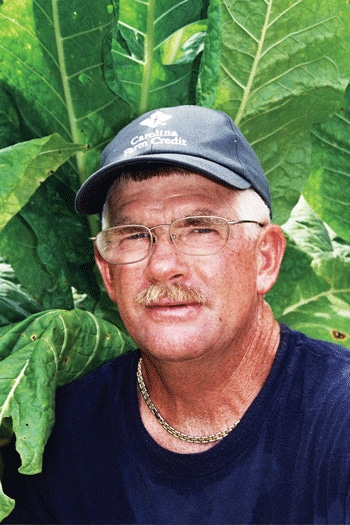

But Bobby Baker of Ellisboro, N.C., in the North Carolina Piedmont near Greensboro, who has experimented with all the harvesting methods available in five seasons of burley production, says the old-fashioned way is the best.

“I have found ‘spearing’ on sticks to be much faster than the other options,” he says. “And my workers like the stick better.”

Mechanical burley harvesters called notcher-cutters are available that have been proven to be functional in the field. They cut off the stalk close to the ground, notch it and convey it to a cart or trailer for transportation to a wire-strung curing facility.

Performance issue

Substantially less labor is required, but few are in use. Why? There is a performance issue. Burley growers have frequently reported some problems with leaf breakage with mechanical harvesters. Baker experimented with a notcher-cutter in 2007 and wasn’t satisfied.

“The year we used it, we lost a lot of the lower stalk because of the extra handling that was involved,” he says.

There are compelling economic obstacles to mechanizing burley harvest. Most burley operations remain relatively small scale compared to flue-cured operations where mechanical harvest has been adopted, saidUniversity of Tennessee agricultural economists Vickie Witcher and Jane Howell Starnes.

When you factor in the extreme uncertainty many burley growers have encountered relative to contract demand, it creates a climate where the high cost of harvest mechanization doesn’t seem justified to most burley growers, they say.

Furthermore, labor is readily available in this time of economic depression, so growers have been able to get their tobacco cut and ready for market without the upfront costs of mechanical aids.

Baker, a life-long flue-cured grower, began growing burley right after the buyout. Now, with his sixth burley crop nearing completion, he thinks he made a good choice.

“Burley really helps in labor utilization on a flue-cured farm,” says Baker.

Baker normally harvests his burley in August and strips in November or early December.

Late harvest

“But this year I am afraid harvest is going to be late,” he said in late July. ”It was very dry so far. The heat and lack of water really took a toll on the burley. Some was just coming into top late in July.”

That was a change from the past. “All five of our previous crops have developed in a timely manner,” he says.

Once his burley is on sticks, Baker hangs them in a three-tiered pole barn. It has a permanent roof but is open on the sides. He covers the sides of the barn with plastic once he loads it.

If he needs additional curing space, he also has a one-tier outdoor curing structure that he can hang sticks in and cover with plastic.

The same migrant crew works on both types in the field.

In the barn, he usually has a four-man burley stripping crew. Each takes one stalk position and passes the stalk down with a conveyor belt made from an old flue-cured tobacco looper. They drop the leaf into boxes behind them and bale when the boxes are full.

Through July, irrigation was the most important practice on Baker’s farm. “We irrigate with portable pipe and sprinklers,” he says. “We have three ponds and have already depleted two of them. We won’t have enough water if this drought continues.”

He might purchase a reel-type traveling gun for 2011. “That would really conserve the water.”

One other change for 2011 may be in his choice of flue-cured variety. He is experimenting this year with seven acres of the new flue-cured variety CC 35, which is said to have the best holding ability of any variety on the market.

“I have seen it on other farms,” he says. “It will sit on the land and wait.”

He hopes it will provide extra time in harvesting and help with barn utilization.

He was forced to reduce burley plantings because of lower contract demand.

“We are down three or maybe four acres,” he says. “We went from 12 acres in 2009 down to about nine. We still have close to 60 acres of flue-cured, which is about the same as last year.”

e-mail: [email protected]

You May Also Like