October 1, 2023

For several reasons and factors, we are seeing a movement towards reducing or even eliminating fall tillage from many acres across the US. With increasing costs around equipment, lack of manpower, and pressure for conservation from outside of agriculture, it is doubtful this trend will lose steam any time soon.

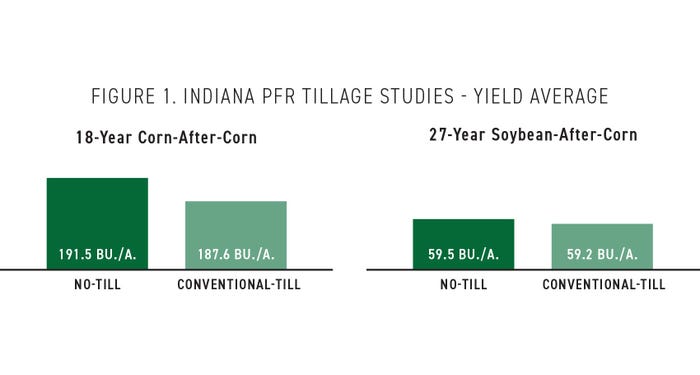

Can high yields be sustained while moving to a program like no-till? Let's examine Beck's 2022 Indiana PFR tillage studies for corn and soybeans. These studies showed dramatic results with an average of 37.9 Bu./A. advantage on corn and a 3.4 Bu./A. advantage increase on soybeans when no-tilled. While these results may seem unbelievable, they are supported by multi-year data showing a 3.9 Bu./A. advantage to corn being no-tilled over 18 years and 0.3 Bu./A. advantage to soybeans being no-tilled over 27 years of testing (Figure 1.)

Photo submitted by Beck's Hybrids

This may surprise some as many see no-till planting as yield-limiting and, very rarely, yield-enhancing. We also must remember that moving to complete no-till is a systems approach; the most significant benefits are found once the microbial environment of that soil profile is allowed to come alive and thrive. While there are products to feed that community, it may take a few years to build up microbial levels to quickly break down residue and reap the full benefits.

As we consider the potential yield increases with no-till, we do have to address the negative aspects of this practice. Weed control and residue management can become an issue as tillage is taken away as a tool in the toolbox. Controlling winter annual weeds, like marestail, can become more challenging as we remove tillage. Not only can these weeds be tough to kill in the spring, but they can also serve as a host for pathogens and insects to overwinter.

This is why we look to fall burndown applications to increase control and allow for the cleanest fields as we start the spring. These can be as simple as a mixture of glyphosate and 2,4-D if infestations are low but may need the addition of a Group 15 residual herbicide due to the elongated germination windows we see with many winter annual weeds.

Secondly, when tillage is removed, we lack the integration of residue into the soil to begin pushing that debris to break down. This problem can be combated in a few different ways.

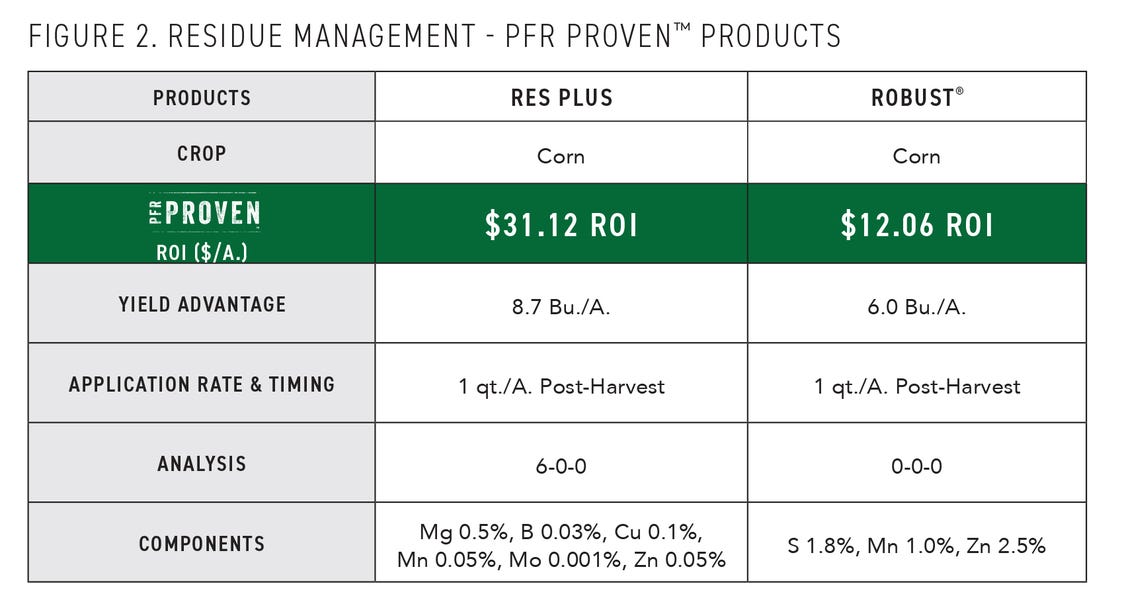

The first is newer and can be added to our fall burndown application. Stalk degradation products focus on feeding and stimulating microbial activity within the soil to hasten the breakdown of heavy residues (Figure 2.)

Photo submitted by Beck's Hybrids

The faster these residues can decompose, the faster the nutrients contained within them can be released back into the soil surface for use in the next crop. When moving to reduced tillage, we really need to look at the microbes in the soil as employees on the farm, helping to return valuable nutrients to us, but they also need to be fed to work efficiently.

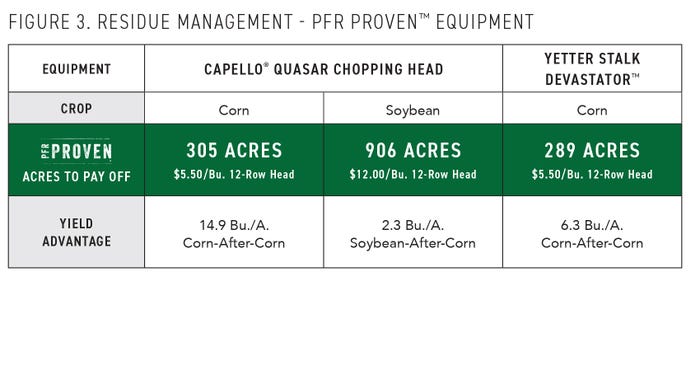

Secondly, there are two different harvest attachments to our corn heads that have become popular in this space (Figure 3.)

Photo submitted by Beck's Hybrids

The first, chopping corn heads, work to physically chop and size the corn stalk that is left above ground. This sizing allows for faster microbial breakdown and better field conditions in the spring, as the old corn rows are not as difficult to fight. One thing to watch is that in fields that are prone to running water, these residues can easily move a bunch up in lower areas. Stalk Stompers are our second option; these are less mechanically involved and basically just push the old corn row down and fracture that residual stalk. While it may not size the residue as well as a chopping head, it still begins that process with less investment. One of the only things to watch with Stalk Stompers is that they may be detrimental when harvesting in wet conditions and may begin to push when it becomes too muddy.

Beck's - Farmers At Heart® - revolutionized the customer seed buying experience by remaining true to a foundation built on faith, family, and farming. Founded in 1937, Beck's appreciates the farmers who have helped them become the largest family-owned retail seed company and the third-largest seed brand in the United States. The Beck family is now in its fifth generation of family members who work in the business to honor God and help farmers succeed. The Beck family and team of employees help farmers achieve success from generation to generation through authentic customer experiences, product diversity, seed quality, and performance. With a home office located in Atlanta, Ind., Beck's serves farmers throughout the Midwest and Mid-South. For more information about Beck's Superior Hybrids, Inc., visit www.beckshybrids.com.

You May Also Like