September 13, 2015

With grain still in the bin, a big crop coming and prices lower than a old barbed wire fence, you're probably going to have to get creative to find enough grain storage this year.

Before filling buildings and bags with grain, or piling grain on the ground, check out these tips from Ken Hellevang, North Dakota State University Extension agricultural engineer and grain drying and storage specialist.

Buildings

Hire an engineer to complete a structural analysis or contact he building company for guidance on how reinforce a building to store grain. The pressure on the walls is immense.

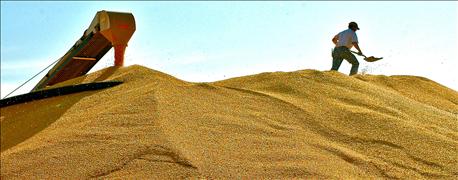

Corn is augered on to the top of a grain pile.

Before placing grain in a building previously used for grain storage, look for anything out of alignment, such as a bowing wall or roofline. Bowing or bending indicates the load on the building exceeds the load for which it was designed and built.

Examine connections for separation or movement. A connector failure can lead to a building failure. You may need to reinforce the connection by adding a gusset or splice.

Bags

Grain should be placed in the bag at recommended storage moisture contents based on grain and outdoor temperatures. Heating will occur if the grain exceeds a safe storage moisture content. Grain in a bag cannot be cooled with aeration. The average temperature of dry grain will follow the average outdoor temperature.

Select an elevated, well-drained site for the storage bags, and run the bags north and south so solar heating is similar on both sides. Sunshine on just one side heats that side, which can lead to moisture accumulation in the grain on the cool side.

Check bags frequently for holes. Wildlife can puncture the bags, creating an entrance for moisture and releasing the grain smell, which attracts more wildlife.

~~~PAGE_BREAK_HERE~~~

Monitor the grain temperature at several places in the bags.

Never enter a grain bag. It's a suffocation hazard. If unloading the bag with a pneumatic grain conveyor, the suction can "shrink wrap" a person so he or she cannot move and will limit space for breathing.

Pile

Cover the pile. Precipitation is a severe problem in uncovered grain. A 1-inch rain will increase the moisture content of a 1-foot layer of corn by 9 percentage points. This typically leads to the loss of at least 2 feet of grain on the pile surface. A 1-foot loss on the surface of a 25-foot-high cone-shaped pile is about 13% of the grain. Aeration and wind blowing on the pile will not dry wet grain adequately to prevent spoilage.

Prepare the ground where grain will be piled with lime, fly ash, cement or asphalt to prevent soil moisture from reaching the grain. The storage floor should be higher than the surrounding ground to minimize moisture transfer from the soil into the grain. Make sure the ground surface is crowned so moisture that does get into the pile drains out rather than creating a wet pocket that leads to grain deterioration. Also examine the entire area to assure that flooding will not occur during major rain events.

A combination of restraining straps and suction from the aeration system holds grain covers in place. However, you must provide inlets for adequate airflow through the grain to control its temperature. Place perforated ducts on the grain under the cover to provide a controlled air intake for the aeration system and airflow near the cover to minimize condensation problems.

Properly sized and spaced ducts should be placed on the ground under the pile to pull air through the grain. If you use a perforated grain wall, the aeration ducts near the wall should not be perforated or the airflow through the grain will be limited to near the wall.

Source: NDSU Extension

You May Also Like