March 7, 2018

You already know that producing protein and energy for less than purchased grain is where potential dairy profits begin. But if you’re still harvesting haylage by date rather than physiological stage, you’re still setting up for a major first-cutting loss — failing to capture optimum haylage quality, warns Tom Kilcer, certified crop advisor for Advanced Ag Systems of Kinderhook, N.Y.

A case in point: John Winchell, Alltech dairy nutritionist in western New York has tracked date of optimum alfalfa harvest based on heat units for the last eight years. For his location, it has ranged between May 16 and May 28. If you use date as your starting point, you’ll hit optimum quality in only one of eight years — not good odds.

The ever-changing climate makes it even more dicey. That’s why heat units or growing degree days are much better predictors of when to start harvest, adds Kilcer.

A more profitable approach

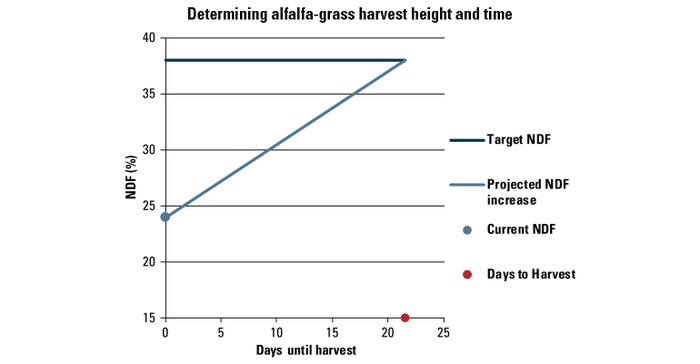

Fortunately, key research by Cornell University forage agronomist Jerry Cherney has developed a system using alfalfa physiological maturity (nutrient detergent fiber) to determine optimum harvest time. You only need a ruler and the accompanying graph generated by Excel software to run it.

Predictive Excel tools for an alfalfa-grass mix, pure alfalfa NDF and grass NDF are downloadable from forages.org. Using a ruler and noting the stand’s grass percentage, you can determine your optimum time to harvest. Based on 38% neutral detergent fiber (adjustable), you select current alfalfa height, percentage of grass in stand, estimate target harvest height and it’ll tell you how many days before harvest. Remember:

• Grass fields are ready often a week or two before all alfalfa fields.

• South-facing fields are ready before north-facing fields.

• Dry fields should be cut before wet fields.

If you don’t look and measure, you’re simply guessing at quality forage harvest date. And, Kilcer stresses, there’s no room for guessing in today’s dairy industry.

Time is quality and money saved or lost

Kilcer pioneered development of wide-swath, same-day haylage harvest close to 20 years ago. The proof of its value is found in forage tests and milk bulk tanks.

“Tests of some non-wide swathed samples I recently looked at were 0.61 net energy lactation,” he says. “Yet a farm in Savannah, N.Y., showed me a wide-swath haylage sample with an 0.71 NEL. That’s almost to corn silage energy levels. That 16% more energy in your haylage can go a long way to reducing milk production costs.

“Yes, it takes some effort to figure it out. You may have to make changes on your mower to get a swath to greater than 80% of cutter-bar width. The biggest adjustment may be between your ears. You have to change ‘what we always did.’”

The money’s on the table. And as Kilcer concludes: It’s up to you to pick it up.

Source: Advanced Ag Systems newsletter

You May Also Like