February 8, 2024

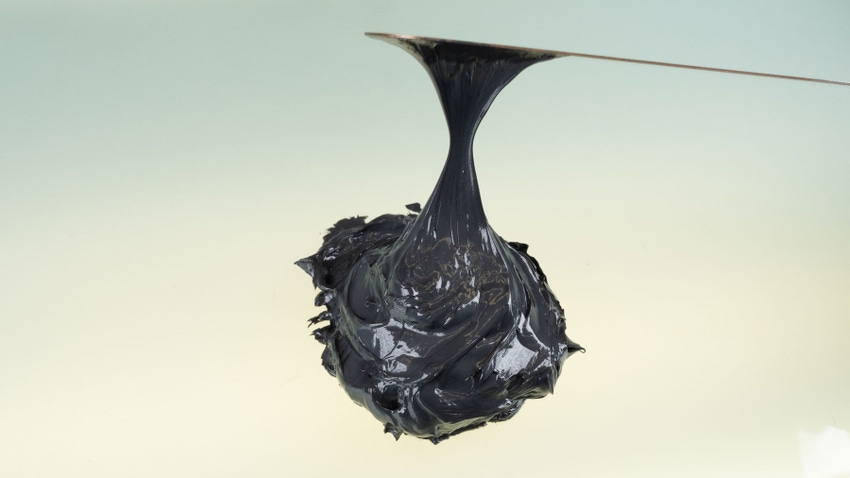

Driven by marketplace demand for a high-performing alternative to lithium-based grease, Chevron has released a new “overbased” calcium sulfonate complex grease into its lineup called Rykon.

Prices for lithium-based grease are up due to rising demand for lithium-powered batteries. In the overbased process, the calcium sulfonate is neutralized with an excess amount of calcium hydroxide, resulting in better protection against wear and metal-to-metal contact.

“With the rise of electric vehicles and demand in electric vehicles, there’s rising cost,” says Zach Sutton, an industrial sector specialist at Chevron Lubricants. “We’ve seen a significant rise in raw materials, and I’m sure your readers have already felt that impact. They’re looking for alternatives.”

The grease is formulated for heavy-duty and extreme pressure applications.

Costly lithium-based grease

While calcium-sulfonate-based grease has been available for some time, it’s historically been more expensive to produce than its lithium-based counterpart. That’s changed over the last decade.

Generally, the percentage of lithium-based grease in the market has trended down from nearly 60% in 2010 to about 40% in 2022. During that time, calcium sulfonate solutions surged from 1% to about 5%, according to the NLGI’s 2022 Production Survey Report. Other alternatives include anhydrous calcium soap grease.

Driving demand, sales of electric vehicles — and their lithium-ion batteries — globally catapulted from about 1 million in 2016 to nearly 14 million last year, based on data from the International Energy Agency. And it’s only projected to increase.

However, producing calcium sulfonate grease hasn’t gotten any less expensive. “From a market perspective, we do anticipate volatility. We can’t predict how long that volatility will persist, but it’s to the point that the market is demanding alternatives to the lithium products we have today,” Sutton says. Calcium sulfonate products are “very similar in cost, and we know we can source those raw materials.”

Rykon’s performance

While stabilizing costs is a driving factor, it’s not the only benefit touted by Chevron, Sutton says. In California, Rykon was used with heavy machinery in a summer field trial. The machinery consumed a third less lubricant than similar lithium-based products — from a medium-flow setting to a low-flow setting.

“We’ve always seen overbased calcium sulfonates as a higher-performing grease,” Sutton says, noting its ability to “deter water ingression,” which can protect vehicles from failure. “The key element is that the grease will stay in place, and it prevents water from contacting surfaces.”

Sutton says the grease surpasses the highest standards set out by the National Lubricating Grease Institute, not just the industry-baseline standard of GC-LB. This performance durability increases uptime by extending lubrication intervals, preventing breakdowns and reducing the lifetime cost of equipment ownership.

Along with exceptional oxidation and thermal stability, Sutton notes Rykon’s ability to handle extreme loads and pressures in “very hot, dirty environments. It ensures it protects those moving components.”

A specification sheet from Chevron notes that Rykon is designed as a multipurpose, heavy-duty lubricant for general and industrial farm use, from medium- to heavy-duty front-steer and articulated tractors and loaders to larger rubber-tracked units. The product can be used in many applications including three-point hitches, high lift pins and bushings, and other heavy-duty machinery.

The product is compatible and safe to use with other types of grease, although Sutton notes, “We always recommend definitely purging your system to ensure maximum performance.”

About the Author(s)

You May Also Like