December 26, 2013

The 21st Century miracle material is carbon fiber. Just ask Boeing, which created and builds the Dreamliner 787 with a carbon fiber structure, which reduces weight and improves fuel efficiency. For sprayer companies, the holy grail has been a dependable carbon fiber spray boom and while it's been tried in the past, the success rate has been variable.

Turns out just molding carbon fiber into a boom shape and cutting a few holes into it for tubes and nozzles may not be the best idea for structural integrity and longevity. The folks at Altek International, based in the UK, have been eyeing the idea of a carbon spray boom for some time.

One of its subsidiaries has had significant results in the carbon fiber business making bike frames for competitors, including the now discredited Lance Armstrong (nothing wrong with his bike). And given all that development work it took some time to get around to developing that ag spray boom.

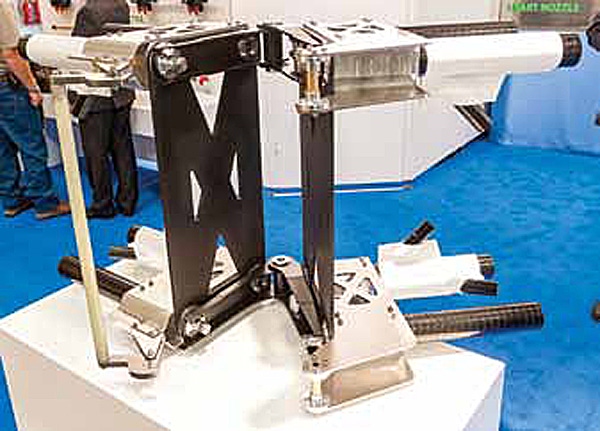

The boom you see here has carbon-fiber as the key tube design (the black parts), those gray structural pieces are fiber glass, and the boom also uses aluminum blocks for strength too.

But at Agritechnica, they showed off the design, which looks more like a conventional spray boom that you might expect. The tube and gusset design uses carbon fiber for the tube shape, but the structure is fiber glas. And key parts of the structure are still steel, because people like to "hang things" off a sprayer and steel still makes the most sense.

Those carbon fiber bars are formed from carbon filament wrapped into a tube shape, creating an extremely strong structure. Those "tubes" look like they're made of tape wrapped around a form and in fact that's pretty accurate.

The aluminum blocks you can see in the close-up act as a base for each boom. Nozzles are still attached to a stainless steel tube, but there's a significant weight advantage when you can make the structure from carbon fiber.

Dropping weight

The move to carbon fiber is about getting the performance of steel or aluminum with a weight savings - and carbon has flex and performance properties that rival those two other materials as well. For Altek, the result is a 120-foot spray boom that weighs in at 850 pounds.

The lower weight is about half that of an aluminum spray boom - the current favorite for weight-saving designs in the sprayer industry. The same boom made of steel would weigh three times as much.

Of course, what you see here is still in the prototype stage, but Altek's management says they had plenty of visits from original equipment sprayer makers interested in exploring tests with the boom next season and beyond.

As prayers get bigger, weight becomes a concern. A lower-weight carbon-fiber boom could help solve some of the problems.

You can learn more about the company - but not its spray boom - by visiting altekinternatinoal.com.

Like what you’re reading? Subscribe to Farm Industry News Now e-newsletter to get the latest news and more straight to your inbox twice weekly.

About the Author(s)

You May Also Like