There is great allure to shiny new farm equipment, until sticker shock sets in. That’s why many producers are looking at their older early-2000s and even 1980s- and 1990s-working-class tractors and machinery more lovingly these days.

Whether these pieces are already stored safely in your shed, or you come across them at local or online machinery auctions, that older, well-maintained equipment has great value if it is in good running condition.

Most likely, these pieces won’t cost you as much by way of payments, and they are often easier to repair and maintain yourself. But does older equipment really pay when you have a lot of acres to cover?

Farm Progress asked a couple of Nebraska Extension agricultural economists to talk about this concept and to walk through some scenarios to help farmers make good buying decisions when it comes to equipment.

“Machinery markets for different types of equipment appear strong in the early winter of 2024,” says Jim Jansen, Nebraska Extension economist. “Operators still looking for quality equipment compete with other farms or ranches to acquire equipment of various ages. New prices remain high for tractors, combines and related equipment. Higher newer equipment prices have led to stronger prices for good used equipment. Lower-hour front-wheel assist tractors from the 1980s, 1990s and 2000s appear to be a strong market point.”

Ability to repair

“Older equipment may not have as many proprietary electronics, allowing farmers or independent repair shops to troubleshoot and repair this equipment,” Jansen adds. “The ability to fix and repair the equipment seems to be a major reason for these used purchases.”

Availability of aftermarket parts for certain models is also a consideration for producers looking at older-model machinery.

“Operators looking to repair their equipment consider using aftermarket parts in some instances,” Jansen explains. “Some aftermarket parts might be priced more competitively than those from the dealership.”

OLDER IS OK: There are some advantages to running older equipment under certain circumstances, including the fact that it may be easier for the farmer to repair themselves — and lower-priced parts may be available, depending on the implements being repaired.

And you can’t overlook cost of acquiring equipment as an influence on the decision to buy used versus new. There is also the impact of older equipment on insurance and taxes to be considered.

Farm Progress asked Nebraska Extension economist Glennis McClure to run some scenarios, trying to get a handle on costs of ownership between good, used equipment versus purchasing newer machinery.

In comparison

Comparing the purchase of a 2022 newer model Case IH Magnum 340 tractor and a Kinze 3600 16-row planter versus owning a 2014 older, used model tractor and 2015 planter of the same models and brands, you can get an idea of some of the considerations between used and newer machinery, McClure says.

To demonstrate, she compared the estimated purchase price for a 2014 Magnum tractor at $200,000 and an older Kinze planter with an estimated purchase price of $65,000. For the newer 2022 models, estimated purchase prices of $355,000 for the Magnum tractor and $140,000 for the Kinze planter were used.

But you need to look beyond the purchase prices, McClure notes. “I ran figures for the older tractor and planter and then using the same brand that were several years newer,” she says. “I ran it through the UNL Ag Budget Calculator program and in spreadsheet format.”

She says that if both tractors run with the same fuel efficiency — which is a key consideration — you would note that repairs, which were calculated using the American Society of Agricultural and Biological Engineers standard formulas, are higher for the older equipment. “Depreciation is lower for the older equipment due to the lower purchase costs, generally speaking,” McClure says.

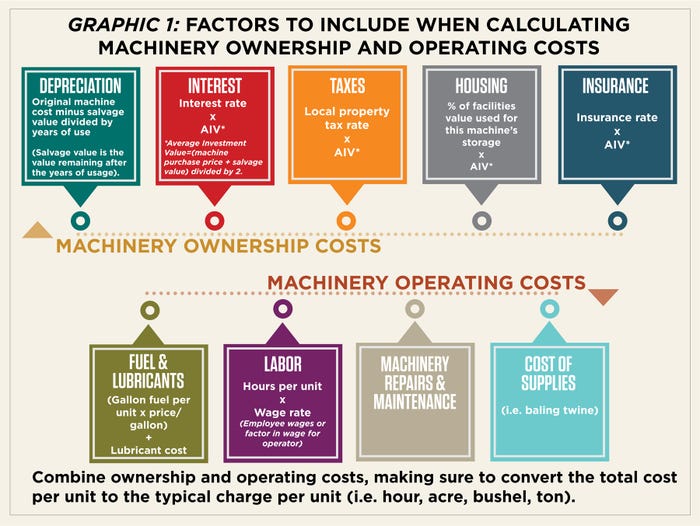

Other costs such as personal property taxes, insurance and housing are not shown on the ABC report, but they should be figured based on the average investment value, which is also lower for the older machinery.

Bottom line for older equipment

In McClure’s examples for the older equipment, the total operating cost per operating hour was $97.80 for the tractor and $70.60 (representing repair cost per acre) for the planter. Adding ownership cost of the tractor and planter to operating costs, the total per-hour cost figure is $475.68.

If the tractor and planter cover 15.5 acres per hour, the total machinery and equipment ownership and operating costs would be $30.69 per acre.

Bottom line for newer equipment

In McClure’s example for the newer tractor and planter, the total operating costs per operating hour with all costs included, calculated to $91.39 for the tractor and $30.53 (estimated repair cost per acre) for the planter, which is less than the numbers for the older equipment.

If used in combination, total ownership and operating costs per hour were $793.40, which is much higher than the older equipment because of higher ownership costs on a per-hour basis of use. If the tractor and planter cover 15.5 acres per hour, similar to the older equipment scenario, the total machinery and equipment ownership and operating costs per acre would be $51.19.

So, the older equipment, due to lower ownership costs in general, would be less expensive to own and operate per hour in the field by $20.40 per acre, compared to the newer equipment in this particular scenario.

Results may vary

As Jansen suggested, actual ownership costs are going to vary from farm to farm, depending on the farmer’s ability and willingness to conduct their own repairs, along with other variables between operations.

As McClure suggested, a key consideration in this comparison is fuel efficiency between the two tractors, as well as the ownership cost difference between the older and newer (higher-priced) equipment. The type of tractor and planter, size and age all play as variables in these kinds of comparisons.

But certainly, both Nebraska Extension economists agree that the comparison is worth considering, in light of recent market trends for machinery.

Learn more at cap.unl.edu.

About the Author(s)

You May Also Like