December 25, 2017

By Jeremy Hughes

In today’s high-tech world of row crop planting, it is very easy to get wrapped up in the excitement of new technologies. Even though most truly sustainable yield gains come through advancing seed genetics, never before have there been so many products on the market that promise an ever-increasing horizon of yield bumps. Adding a bushel here, possibly adding 1.5 bushels there and even a promise of 2 bushels more per acre are messages constantly bombarding row crop farmers.

We also get stars in our eyes on promises of that elusive extra 2 to 5 bushels that somehow we really are never able to quantify after our investment, even though we may “feel” there was a difference. “For a moment, we need to take a deep breath and ask ourselves this important question before the 2018 planting season: What adds more to my bottom line — promises of insignificant and unrepeatable yield increases, or managing to secure my maximum yield potential by reducing the risk of proven significant yield impacts?”

Planning for 2018

Look at the commonsense basics of securing corn and soybean yields. When you have a corn or soybean seed in your hand, at that point in time you hold the moment where you have maximum yield potential of that crop. Once seed goes into the planter hopper, our job as farmers is simply to reduce the negative yield impacts to the seed. Successful planting takes much more than seeing 99.9% singulation on the monitor. Unfortunately, such advancements in planter technology have caused many farmers to forget about the two most important tools for ensuring planting success: your pocket knife and time.

Even with the fancy monitors and sensors on planters today, there is no substitute for getting out of the cab, getting on your knees and digging in the rows. Doing this is not “old school” or behind the times. It’s what separates tractor drivers from true planter operators. Monitors and sensors only give a snapshot of what the planter is doing. The final outcome of planting occurs once the seed is at its final resting place in the furrow. Analyzing the seed’s position and the soil conditions in which it lies are two very important benchmarks to secure yield.

Additionally, when comparing a successful farming year to an unsuccessful farming year, it comes down to one dynamic and one dynamic only: timing. Whether it’s selling your grain, spraying fields, fertilizing, buying machinery, harvesting crops or planting, timing will either be your profit or loss. Let’s take a look at these significant yield impacts in corn.

Seed placement. Is seed spacing or seed depth more important? In reality, it’s seed depth. The depth of your corn seed plays a vital role in securing yield. Looking at long-term studies by seed companies and universities, placing seed shallower than 1.5 inches will risk yield losses by 4 to 6 bushels or more per acre. The only way to confirm depth is to get out of the cab, get on your knees and dig for seed. Benchmark each and every individual row unit of your planter as you change fields and as conditions change.

Not only setting the correct depth, but using proper planter technology to maintain that depth, is crucial to your bottom line. Stabilizing the row unit to keep consistent disk opener engagement is an important key to maintain desired depth. Preparing a good seedbed and properly adjusting row cleaners also play into this equation. Remember, depth is determined by the gauge wheels, and depth control is only as good as the area they roll over.

Furrow integrity. Ensuring the integrity of your furrow involves two main dynamics — managing sidewall compaction and reducing the effect of pinch rows. One of the biggest mistakes in planting is sidewall compaction, caused by too much row unit downforce and planting in less-than-optimum soil conditions. Sidewall compaction accounts for yield losses of 30% to 40% in corn. Placing the seed into a smeared furrow creates a less-than-suitable environment for early seedling growth, and stunts future productivity of the plant. Even with auto downforce systems, you still must set parameters. Only by getting out of the cab, getting on your knees and digging to examine the integrity of your furrow can proper down-pressure adjustments be made.

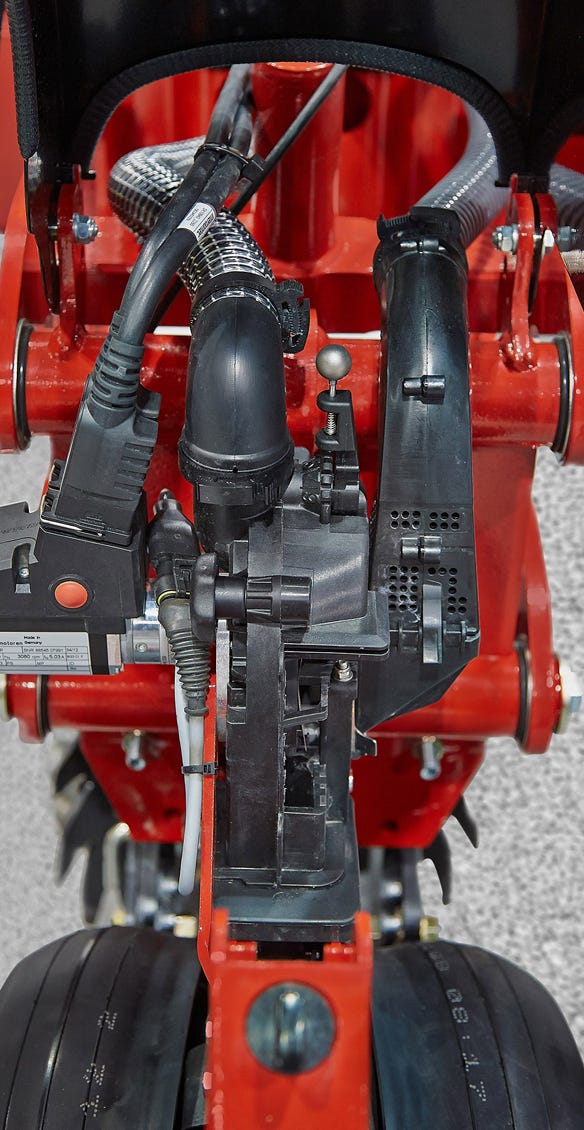

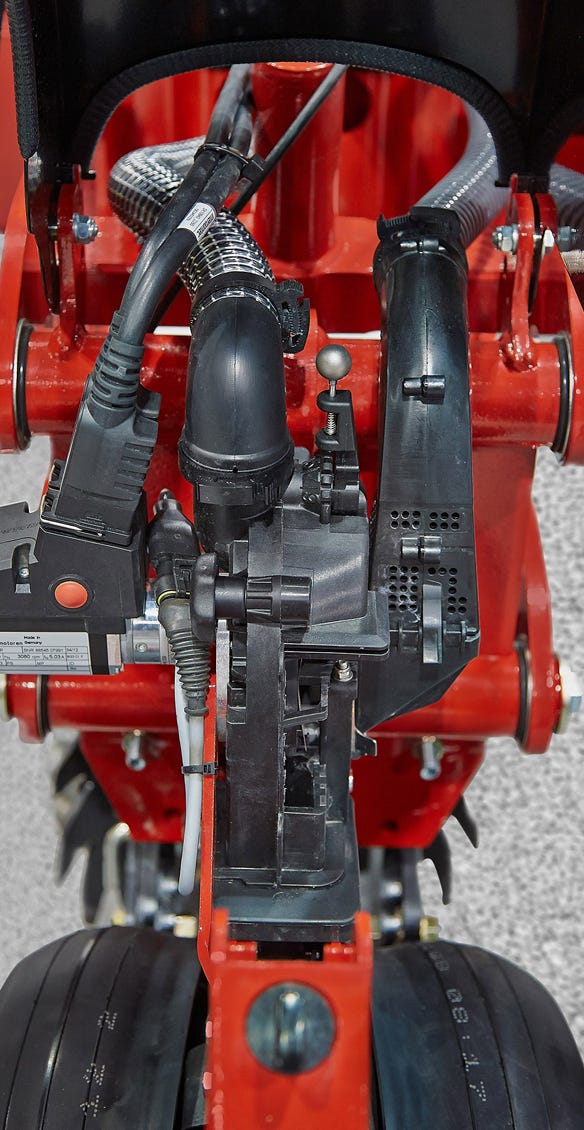

EACH ROW UNIT: Check each individual row unit on your planter. Setting the correct seed depth is important, as is stabilizing the row unit to maintain desired depth.

EACH ROW UNIT: Check each individual row unit on your planter. Setting the correct seed depth is important, as is stabilizing the row unit to maintain desired depth.

Pinch rows are caused primarily from the design of central-fill planter toolbars. Heavy planter mainframes, carried by small implement tires, have a detrimental effect on rows beside them. Adverse soil compaction can dramatically reduce root growth, plant vigor and overall yield. University studies show up to a 15- to 20-bushel-per-acre yield reduction due to pinch rows. To put this in perspective, if you are running a central fill planter that is 24 rows and using 30-inch spacing, 25% of your corn can experience yield reduction. If using a 16-row, 30-inch planter, 32% of your corn can experience yield reduction.

We seldom see the results of pinch rows on a combine monitor due to our yield snapshot only being the width of the header, not row by row. However, pinch rows are a hidden yield risk that can be managed. Using planters with larger-diameter tires or track undercarriages for a lighter footprint and systems to transfer the weight of the central fill hoppers to the toolbar will reduce or eliminate the pinch row effect.

Timing. No matter if you are growing corn in South Dakota, Ohio, Missouri or in the heart of Iowa, you have a 10- to14-day window of opportunity to get seed in the ground for maximum yield. This is consistent in most areas of North America and has been proven through years of university and independent studies. Once the planting date surpasses this window, you can expect corn yield drops on average of 1 bushel per acre per day.

For example, the optimal planting date for corn in Ohio and central and northern Illinois is May 1. According to USDA weekly planting reports over the past five years, on average 47% of the corn in Illinois and 21% of the corn in Ohio was in the ground on May 1. The remainder was planted after that optimum date for maximum yield potential. What are the losses to your bottom line simply due to date of planting? Of course, the argument of weather limiting planting progress can be stated; however, the importance of maximizing planted acres per day when the opportunity is present cannot be ignored.

But what about soybeans?

Traveling through the major U.S. soybean-growing areas, I’m often shocked at the overall approach to management of soybean yields. Soybeans sometimes are considered a necessary evil crop only to rotate with corn and aren’t intensively managed for maximizing yield. However, as I look at year-end economic reports, all show, on average, that soybeans gave farmers higher gross margins than corn in 2017. So why are we so emotionally tied to corn that we ignore potentially significant increases in our farm’s gross margin with soybeans? What will you do to secure and enhance the most profitable crop on your farm in 2018?

Timing. Just as timing of planting is a critical piece to securing maximum yield potential in corn, the same is true in soybeans. No matter where you live, you have a narrow planting window to maximize yield. Find out what these dates are for your area. In many areas the yield window of opportunity for soybeans overlaps with that of corn, and once you miss this window of opportunity, losses can be 0.4 to 0.7 bushel per acre per day. When you look at the pinnacle dates versus USDA planting progress, some major growing areas plant 60% to 70% of their soybean crop after the window has passed.

For example, if you were 10 days late getting the last 500 acres of beans planted, that’s potentially $30 to $60 per acre, or up to $30,000 in lost revenue on 500 acres. This is money thrown out the window simply due to late planting. Incorporating higher seed carrying capacity planters to gain more acres per day and potentially adding a planter due to overlap of optimum corn and soybean planting windows can help you secure soybean yield potential.

Row spacing. An interesting topic the past few years, verified by many research projects, is that less than 30-inch row spacing in soybeans can add bushels. Many repetitive trials across the Corn Belt and into the Northern Plains show going to 20-inch or even 15-inch rows can sustainably boost soybean yields by 3 to 5 bushels per acre. At today’s prices, simply changing row spacing could positively impact your bottom line by $30 to $45 or more per acre. I encourage you to check research results in your area.

Seed placement. Last summer I read research studies from different universities in the Corn Belt that had surveyed fields in their respective farming areas. The survey consisted of several questions on soybean crop practices. One question was: “How deep do you plant your soybeans?” In conclusion, 40% to 60% of the soybeans in these areas were planted at an incorrect depth. Study after study shows on average and in most conditions, soybeans should be planted at a 1 to 1.5 inches deep. Planting shallower, which many are tempted to do, sacrifices yield.

Research over the years has shown that “just getting beans in the ground” doesn’t pay off. In fact, most studies show a yield deficit of 3 to 8 bushels per acre. At $9 beans, planting too shallow is a $27- to $72-per-acre risk. That kind of margin is worth getting out of the tractor cab, getting on your knees and adjusting seed depth. Not only setting the correct depth, but also using proper planter technology to maintain that depth is crucial to your bottom line.

Hughes is a farmer and is product manager at Horsch, a seeding and tillage equipment manufacturer. For more information, visit horsch.com.

You May Also Like