Okay, so it may not be a ‘50s sci-fi blockbuster. But it does sound like something from an H.G. Wells novel: 3D robot printers creating objects of almost any geometric shape – including farm equipment parts.

It's something agricultural equipment companies have been using more and more in recent years.

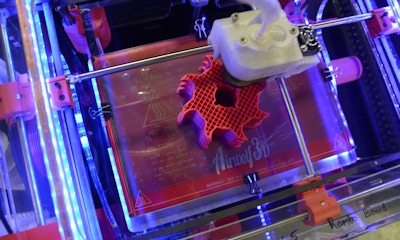

Engineers at 360 Yield Center of Morton, Ill., showcase the use of 3D printing technology to make prototypes of its 360 CHAINROLL stalk roll system.

"We have eight 3D printers for 25 engineers, and they have been a big part of the design process," says Tim Sauder, director of product development at 360 Yield Center, Morton, Ill. "Early on it would take a week or even two weeks to develop our prototype, and we can now print a prototype in 24 hours. We can have a part created overnight, and it's ready the day after. We've got a part we can actually use. It's really about speeding up the innovation process for us."

Sauder says 360 Yield Center uses a 3D design program like Pro/Engineer or SolidWorks to design the dimensions for the product before exporting that design to the printer's computer, which uses polymers or similar material to accurately print the design layer by layer – from 10% fill up to 100% fill.

"It will print almost a full section of the 360 CHAINROLL itself," Sauder says. "Early on in the project, we might do a light 10% or a little more than that and get it out as fast as we possibly can, but once we know the design is coming together, we'll make a full print, and so far, we've actually been able to use most of the products in real field conditions. It helps learn whatever we need to know for the final product."

And Sauder says those prototypes hold up surprisingly well in field tests. "It's not like it's something that just sits on display," he says. "The 360 CHAINROLL itself is a casting, but for prototyping we're able to get quite a few runs out of a plastic part in a few runs in the field. We've been able to run plastic parts in testing underground and they've held up in testing there as well."

Faster to market

The big benefit of using 3D printing to develop prototypes, he says, is the speed of production and how it helps in the overall design process.

"There's a limited window in the season we can test products like the 360 CHAINROLL," he says. "We're using it to chop up stalk residue and create small pieces. We don't want confetti because it's hard for the planter to manage the residue, but we want to fracture enough to flow through tillage and start to microbial breakdown quicker."

Stalk conditions change as the plants dry down, and with prototypes, it's important to test different designs in those different conditions. With 3D printing, Sauder notes, it was easy to print prototypes quickly to test and adjust designs for these different conditions.

"We've worked through probably 40 iterations to come up with the current design," he says. "With the conditions we had in the fall, we could run the designs in the lab, and print a new design every day as those stalk dried down and the season progressed. We were able to adjust day by day on the fly."

"The vast majority of teams designing products for agriculture are using this kind of technology. If they aren't, I think they will be in the near future. I think it's probably going to stay more on teams developing new products than farmers using it to print parts," Sauder says. "I think it's helped make us faster, leading to better designs, and do that at a tenth of what it could cost to use other services that would take longer."

- Harris is editor of Nebraska Farmer, Penton Agriculture brand

About the Author(s)

You May Also Like