December 16, 2015

A recent study by the irrigation water management group at the University of Arkansas evaluated about 66 irrigation pumps for performance. Some of the testing included on-site evaluation (spot-testing), but about half of the pumps had three years of pump monitoring data, hourly data on flow, pressure, and energy use.

A pump monitor is a device that collects flow, pressure, energy use in real time and transmits it by cellular data connection to a central server. The data is available on the internet and smartphones and can be remotely controlled through a web browser.

From the season long flow meter data we found that pumps on average lose about 20 percent of their capacity during the irrigation season.

The range was found to be between 9 percent and 37 percent, a good reason to have a meter on every irrigation well.

Understanding how an irrigation systems capacity changes through the season is a very useful metric. For example, several fields were found not to have adequate capacity to grow rice. While in recent years it has been possible to do it, these growers could be taking an unacceptable level of risk in dry years.

If capacity is inadequate, it may be time to renegotiate rental rates or have the landlord update the pumping plant so the grower is not left with an unacceptable level of risk from water shortage. In some situations, water may be limited already from aquifer drawdowns, and a change in irrigation practice from fully irrigated to deficit irrigation may be necessary.

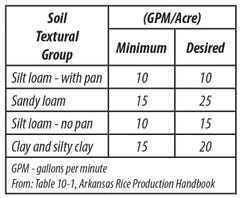

Most corn-rice-soybean systems need 10 to 15 gallons per minute per acre to meet crop water demand.

We used hourly performance data from irrigation pump monitors manufactured by Diesel Engine Motors, a company located in Dardanelle, Ark. We compared the recommended capacities for these pumps to the recommendations in the Arkansas Rice Production Handbook. All of the pumps tested were rice-soybean rotations and they were generally located in the Grand Prairie or northeast Arkansas.

'Sometimes adequate"

Only about half the pumps (52 percent) tested had adequate capacity during the irrigation season for those from the pump monitor dataset and about 42 percent for those that were spot-tested for capacity

From the monitored dataset, only a small percentage, 8 percent, of the pumps tested were inadequate during the entire season. However, 40 percent were “sometimes adequate.” This means the pump had adequate capacity at the start of the season, but could not maintain the minimum recommended capacity for the entire season. So when water demand was the highest, the pump may not have had adequate capacity.

The highest water demand is near the end of the season when farmers are filling and finishing out the grain or seed. For spot-testing, it was found that 52 percent of the pumps did not meet the minimum criteria. Most of this testing was done in the middle of the irrigation season. This data suggests that many farmers may already be experiencing a water shortage, likely from declining aquifers or inadequate pump capacity.

Many things can be done, such as screen cleaning, impeller adjustment, ensuring motor and pump are properly matched, etc. If the simple solutions do not solve the problem, then it is time for upgrading the pump or irrigation management. For pumps serving more than one crop, it is imperative that the capacity be matched to the crop demands, such as having a greater percentage of soybean, grain sorghum, or cotton crop mixes in lieu of corn and rice.

Irrigation capacity is very easy to assess. Guidelines on irrigation capacity for every crop are provided in production handbooks. For Arkansas rice/soybean farmers, the most appropriate metric is Table 10-1 in the Arkansas Rice Production Handbook that outlines minimum and desired capacities based on soil type. This is the same metric used in our study.

Table 10-a, Arkansas Rice Production Handbook

To determine irrigation capacity for a field, simply divide the gallons per minute the pump produces at the end of the year by the acres it serves. If the answer is less than 10, you have a problem for furrow and flood irrigation.

For center pivots, anything less than 5 gpm is unacceptable — the closer to 10 gpm per acre the better. For center pivot irrigation, having good capacity allows for breakdowns and for greater flexibility during the season and a better chance that you can wait to see if a rain can meet water demand.

Undersized systems cannot wait on rains, so in those situations it is necessary to know the soil moisture balance at all times so that rain can be stored and the irrigation system operated sufficiently to maintain a reasonable deficit at the critical growth stages.

Several things can be done to better understand irrigation capacity. Install a flow meter on your pump. Install a pump monitor on your pump. Purchase and learn to use an ultrasonic flow meter or purchase a portable propeller meter to test pumps and risers for flow. Every Extension office in Arkansas has a portable propeller flow meter to be used to check flows at no cost. Many NRCS offices and conservation districts have them also for check-out.

If you have an undersized irrigation system, it may be time to have a discussion with your banker or landlord about irrigation capacity, before the next drought. Based on this study, there is a good chance that inadequate irrigation capacity is occurring on about half of the fields in Arkansas.

Chris Henry, Water Management Engineer, University of Arkansas

You May Also Like