January 30, 2024

At a Glance

- Research trials compared two popular closing wheels vs. standard rubber closing wheels.

- Results indicate a significant advantage for after-market wheels planting corn into cover crops.

- Checking settings and planter performance is also crucial for best emergence.

A cereal rye cover crop prior to corn is a sustainable management practice to improve soil health, reduce soil erosion, remove excess soil nitrate and improve weed management. However, it has its fair share of challenges. Those include reduced nitrogen availability for corn early and planting and emergence difficulties due to high residue levels.

After-market planter technologies like closing wheels and downforce systems are readily available. Research trials at Purdue University were implemented across different locations and environments to test potential benefits of these technologies.

Field-scale research trials were established at the Throckmorton Purdue Agricultural Center (TPAC) in Lafayette in north-central Indiana and the Southeast Purdue Agricultural Center (SEPAC) near Butlerville in southeastern Indiana in 2022 and 2023. The goal was to evaluate the impacts of a cereal rye cover crop and after-market closing wheel types on corn emergence and yield.

Trial details

Cereal rye was drilled at 45 pounds per acre. It was terminated with herbicides two to three weeks prior to corn planting. Total cover crop dry biomass levels at termination ranged from 1,000 to 1,500 pounds per acre.

Closing wheels chosen included standard, round, rubber closing wheels as the control, Cruiser Xtreme closing wheels from Copperhead Ag and Cupped Razor closing wheels from Martin-Till. Both Cruiser Xtreme and Cupped Razor are cast-iron closing wheels designed for high-residue cover crop systems. That is why they were chosen for this project.

PLANTING INTO RESIDUE: Various types of closing wheels were compared planting into both cereal rye residue and soybean stubble.

Closing wheel trial results

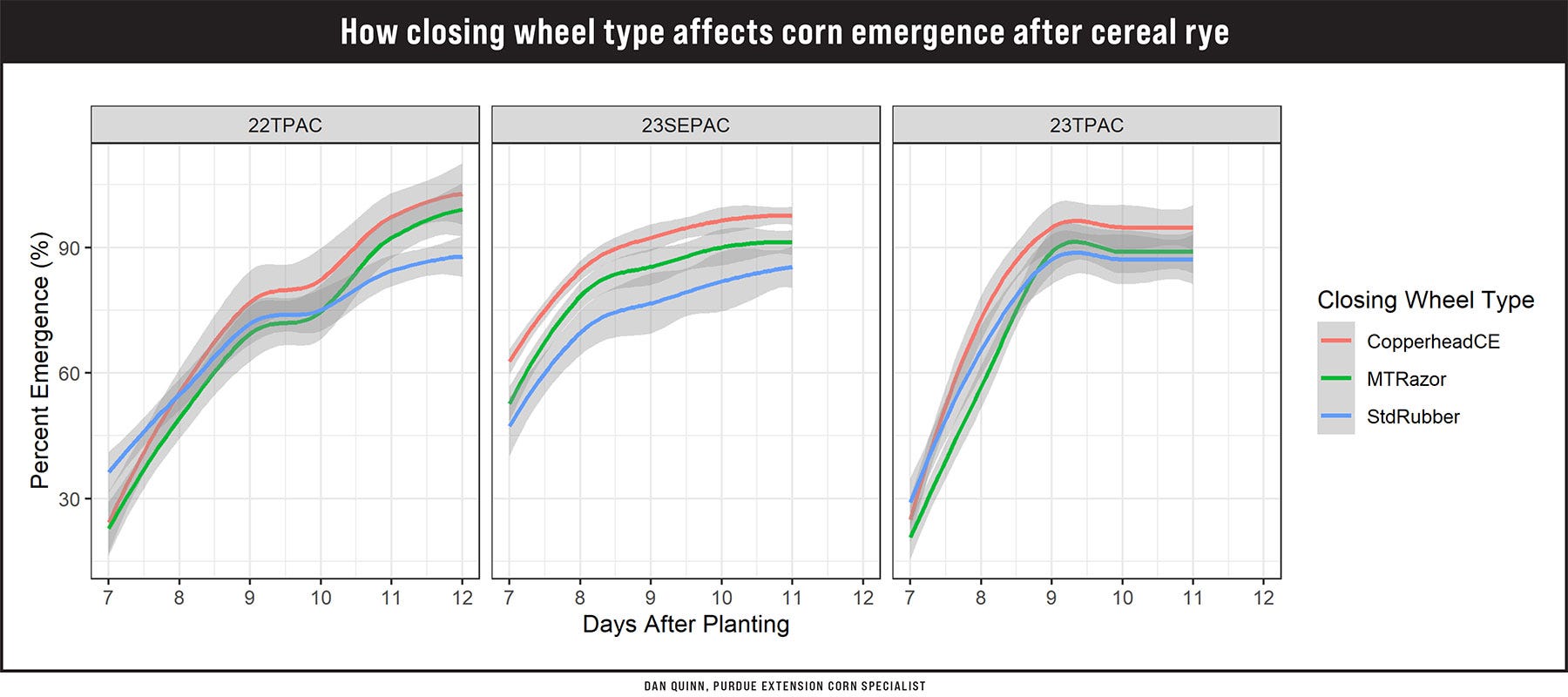

Across three site-years, results indicated both better final emergence and better yield for corn when using either Cruiser Xtreme or Cupped Razor closing wheels vs. standard rubber closing wheels. For example, when combined across all three site-years, the percent of corn emerged at 11 days after planting was 96%, 93% and 86% of targeted seeding rate for Cruiser Xtreme, Cupped Razor and standard rubber closing wheels, respectively.

These graphs show corn emergence differences from seven to 12 days after planting across different site-years and closing wheel types when following a cereal rye cover crop. Gray shading around lines indicates 90% confidence intervals for emergence data.

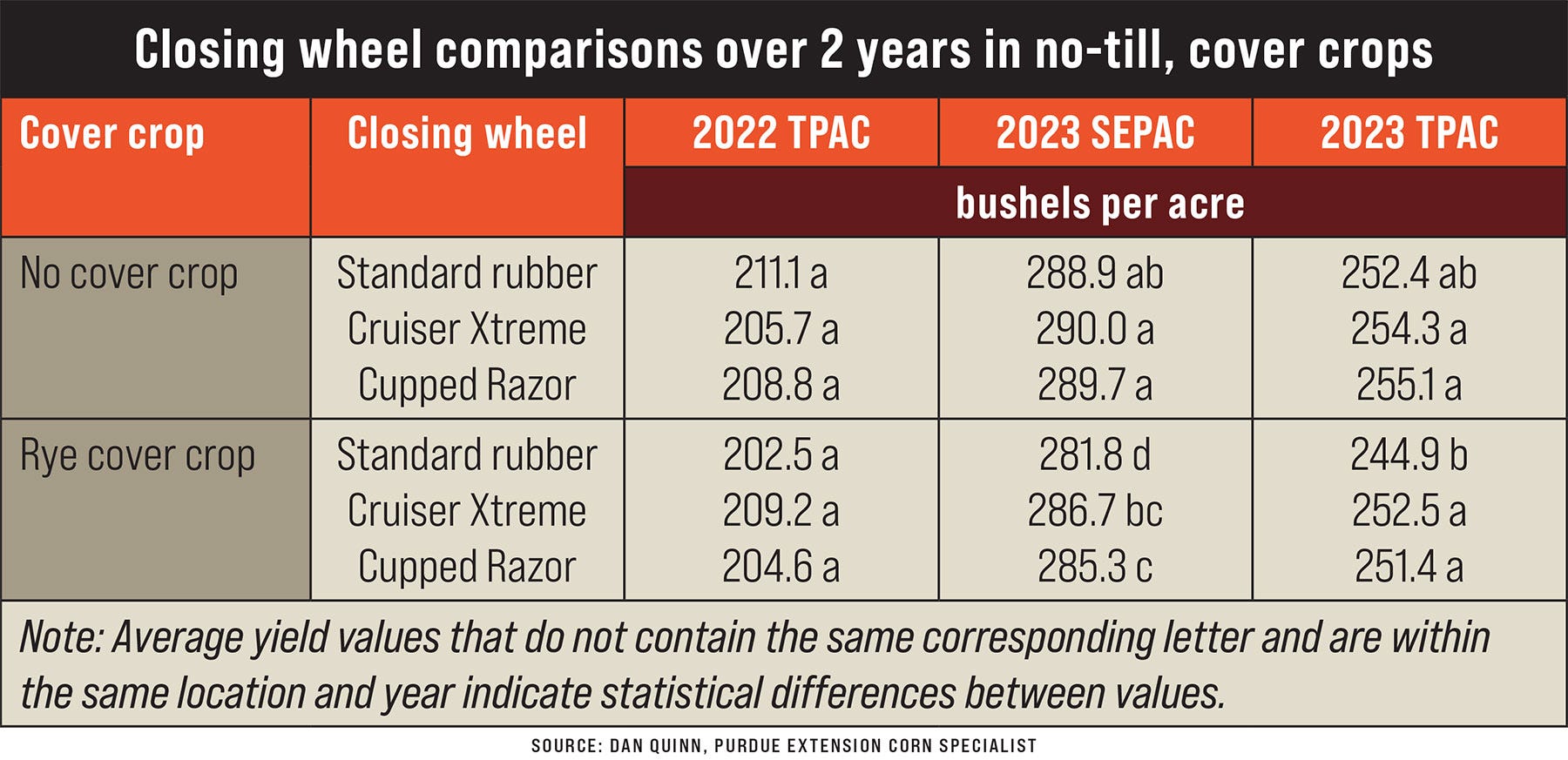

These results translated to yield differences at two of three locations. Yield was significantly increased by 4 to 5 bushels at SEPAC and 7 to 8 bushels at TPAC with inclusion of either Cruiser Xtreme or Cupped Razor closing wheels.

Interestingly, yield and emergence differences were largely observed only when corn followed a cereal rye cover crop. They were not always observed in no-till without a cover crop.

Searching for ‘why’

Why would selecting one closing wheel over another result in potentially improved emergence and yield in high-residue cover crop situations? It is likely through improved residue removal from the seed furrow, plus improved furrow fracturing and closure, and improved seed-to-soil contact.

These results also illustrate the importance of checking and monitoring planting conditions, planter settings and furrow closure conditions regardless of what planter type or technologies are used. This is especially important in high-residue conditions.

Such conditions exist when following a cereal rye cover crop. They may also exist in other situations. In addition, these results showcase the importance of testing after-market planter technologies on your own farm and within different environments to assess potential benefits.

About the Author(s)

You May Also Like