No one wants to experience an accident or loss, yet we plan for those events when we buy insurance.

The same holds true for foreign animal disease outbreaks. No one can predict if and when they might happen. However, we can plan ahead and pencil out an all-farm response plan that incorporates our on-site biosecurity. Having a plan in hand such as this that meets state and federal animal health guidelines demonstrates we’ve taken additional measures to safeguard our animals, and subsequently, move our products to market.

The Secure Pork Supply plan, funded by the USDA Animal and Plant Health Inspection Service and the Pork Checkoff, is a voluntary foreign animal disease program for swine producers that the Minnesota Board of Animal Health is spearheading. With support from University of Minnesota Extension swine specialists, SPS offers pork producers the opportunity to work with plan coordinator Dave Wright to develop their own enhanced response plan.

“In swine, there is a big challenge with movement restrictions if there is an animal disease outbreak. Movement of swine will be restricted,” says Wright, a swine veterinarian based in Buffalo, Minn. Producers are continually moving pigs to different barns or locations depending on the age of the animals — after weaning, to nursery, to finishing, to market.

Completion of SPS allows producers to move animals to processing or other premises under a movement permit issued by MBAH. It also helps the industry maintain business continuity — from producer to hauler to packer — during a foreign animal disease outbreak.

“SPS will help maintain continuity of business,” he adds.

Wright has been traveling the state to promote and educate producers, veterinarians and other swine industry stakeholders about SPS. In a nutshell, there are three components to SPS: traceability and movement management by state animal health officials; enhanced biosecurity on swine farms; and foreign animal disease training for farm personnel in foot-and-mouth disease, classical swine fever or hog cholera, and African swine fever. Producers must recognize clinical signs of disease, document their findings, be prepared to collect samples and contact their veterinarian.

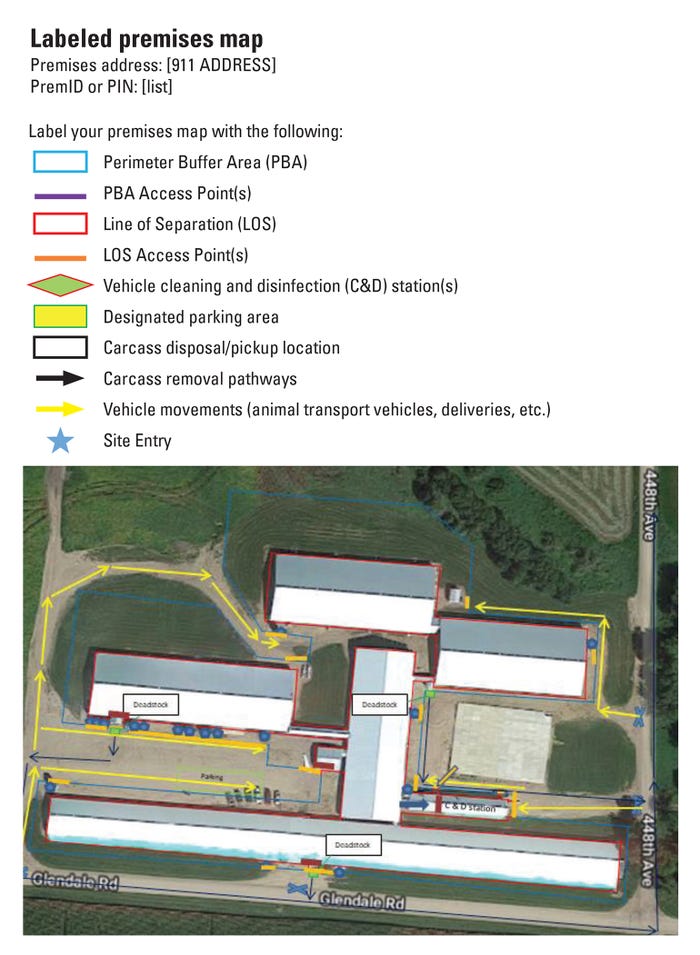

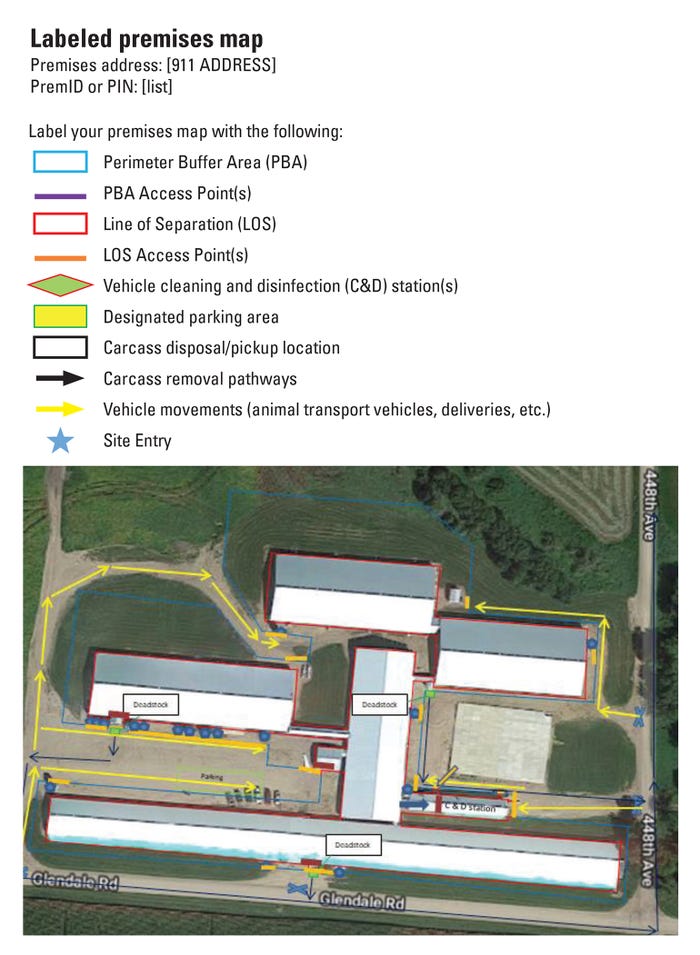

Developing a detailed premise site map is the heart of the SPS plan. The map shows how human and vehicle traffic moves around, into and out of the barn, as well as showing borders, buffers, access points, parking, and sites for animal loading and carcass disposal.

SPS is broken down into seven steps that guide producers through the process of developing a thorough disease response program. The steps are:

1. Familiarize yourself with SPS online at securepork.org and click on the “Pork Producer” tab. Watch the webinar and/or read the various articles about the plan.

2. Validate your premises online using Google, and print a map. Obtain a national premises identification number (PIN), and print off PIN bar codes to simplify paperwork.

3. Locate and compile records: logbooks, certificates of veterinary inspection, standard operating procedures and health production plan movements. All these documents will be needed as you draft your enhanced biosecurity plan. They also will be needed by state animal health officials to easily conduct a traceback investigation if there is an animal disease outbreak.

4. Begin working on your enhanced biosecurity by identifying a biosecurity manager for each site or premises. This person will be responsible for writing the site-specific biosecurity plan, implementing employee training and ensuring compliance.

5. The second part of enhanced biosecurity involves creating and labeling a premises map. This is an important part of biosecurity, and it takes some thought and time to develop. It provides a visual representation of the functional barriers in place to prevent disease from coming onto your farm. At a minimum you will need to identify site entries, lines of separation, access points, designated parking, cleaning and disinfection stations, vehicle movements, feed deliveries, carcass disposal, perimeter buffer areas and access points.

6. The third part of enhanced biosecurity covers biosecurity protocols. Reference materials gathered in Step 3 will aid in completing this step. Biosecurity protocols cover everything coming onto and going off-site — employees, visitors, vehicles, animals, feed and manure.

7. Owners and employees must be able to recognize clinical signs and lesions associated with FMD, hog cholera and African swine fever. Train all to observe clinical signs and respond according to protocols, such as recording and reporting health concerns, and calling your veterinarian.

One farm’s experience

Anderson Farms, Belgrade, Minn., developed an SPS plan with Wright. Brothers Jim and John Anderson farm together with Jim’s three sons — Grant, Noah and Isaac. Noah manages the 2,500 purebred Yorkshire sow herd. They sell gilts all over the U.S. and in Mexico, China and the European Union through DNA Genetics (dnaswinegenetics.com).

John says they have worked with Wright on other herd health projects, and he asked the Andersons if they would work with him to develop an SPS plan.

“He asked us if we’d be his guinea pig, and we decided to give it a shot,” John says.

The information Wright shared was an eye-opener for them all.

“If a foreign disease outbreak happens, it would shut us down with our breeding stock, and we couldn’t move pigs,” Noah says. “That scared us. So, we worked on thinking things out. If you have a[n] [SPS] plan done, you would be one of the first to be able to ship and move pigs again [after an outbreak].”

As they sat and worked through the seven steps with Wright, they learned they already had a lot of the information in place with their own biosecurity plan.

“Now, we have enhanced biosecurity,” Noah adds.

The Andersons had premise IDs for each of their 10 sites and other biosecurity practices in place, such as shower-in and shower-out for their barns, cleaning and disinfecting stations and on-site trailer washing. However, they did need to designate a biosecurity manager for each site, design a very detailed biosecurity site map, provide additional training for employees, delineate site entry, secure buildings with keypad locks on each door and provide more signage.

Working on the site map took the most time and prompted the Andersons to tighten up access points further. For example, at the site entry in the driveway, they plan to erect wooden fence posts and have a chain and lock available there. They also needed to determine a whole-site perimeter buffer area — something they hadn’t considered before.

“Dave was helpful,” John adds. “He also helped us figure out a contingency plan for when animal movement would be interrupted.” They determined they would have feed available for one week, have euthanasia supplies available, and could still compost carcasses a half-mile from the site.

With feedback from farmers he has worked with, Wright continues to streamline components of the SPS process, such as reworking forms so that repetitive info can by copied and pasted in.

At this point, Wright is contracted to serve as SPS coordinator in the state through June. He encourages swine producers to contact him if they have questions or are interested in SPS. Email him at [email protected] or call 763-242-7535.

Check out the SPS plan at securepork.org.

Learn more about the seven SPS steps on the U-M swine Extension blog.

About the Author(s)

You May Also Like