September 26, 2018

Source: South Dakota State University

By Adam Varenhorst, Amanda Bachmann, Philip Rozeboom, and Patrick Wagner.

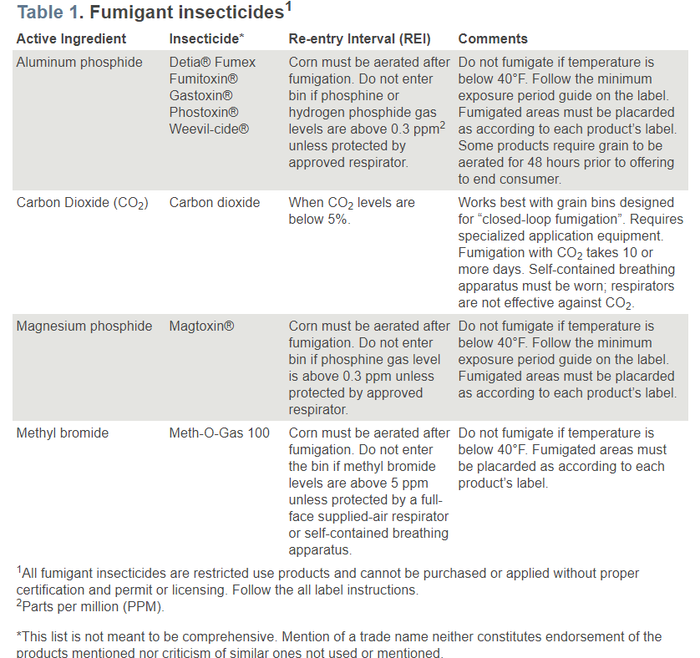

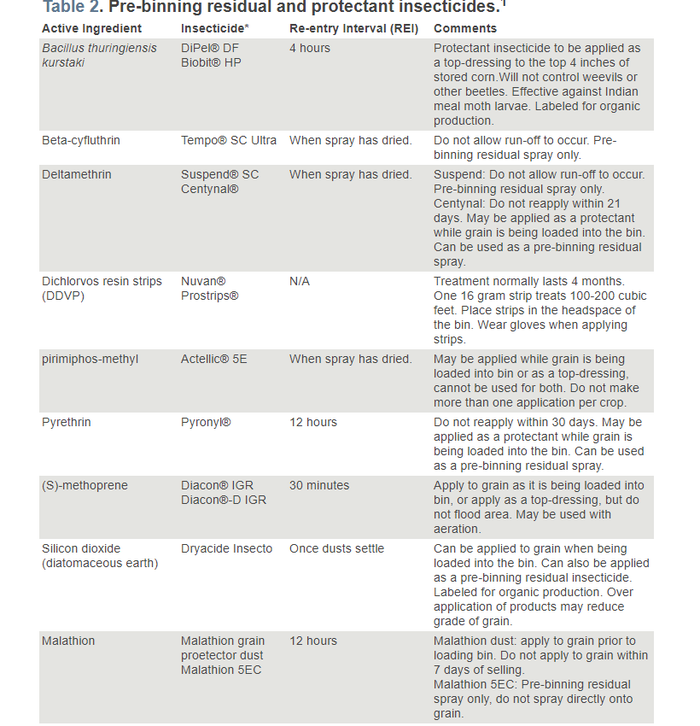

Throughout the year, it is possible to find an infestation of insects in stored grain. The general rule of thumb is the longer grain is stored, the greater the chance of an infestation occurring. As mentioned in a previous article, there are many important steps to be taken to reduce the likelihood of infestation. Under most storage circumstances it is not necessary to treat grain with a protectant insecticide prior to binning (See Table 2 for information on protectant insecticides). This is true for grain that will be removed from storage by May or June of the following spring, or that will be used on-site as livestock feed within one year of harvest. A protectant insecticide should be applied to grain that is expected to be stored for more than one year. If a protectant insecticide application is necessary, it should only occur after the grain has reached the optimal storage moisture. These insecticides can be applied at the auger while the bin is being filled, or as a surface treatment that is referred to as either top-dressing or capping-off. When inspecting stored grain, it is important to remember the potential hazards of grain that is in storage. If an insect infestation is detected in stored grain the grain can either be moved and have a protectant insecticide applied, fed to livestock as-is, be sold at a reduced market value, or be fumigated (Table 1). Due to the hazardous nature of fumigant insecticides we strongly recommend that the application of these is done by a hired professional. Many of these products are activated by moisture, including the moisture present in air. That means the second the seal is removed or the package is opened the product is active. The application of fumigants should be done with a forced air or oxygen provided respirator system to prevent any negative health impacts including death. Always read and follow the label directions when using any pesticide product.

The Seven Components to a Stored Grain Integrated Pest Management (IPM) Plan

Step 1: Structural and Maintenance Components: keep bins clean and repaired.

All season:

Keep a 10 ft. perimeter around the bin free of vegetation and trash.

Clean up grain spills outside of the bin.

Pre-binning:

Bins built on moisture-proof base

Confirm that bin facilities are weather tight and rodent proof.

Screen ventilation openings to prevent entry of rodents and birds.

*Do not mix new and old grain; remove all old grain from bin or fumigate old grain.

*Clean the bin wall, ceiling, ledges, floors, and sills prior to filling with new grain.

*Clean combine, wagons, grain carts, trailers, and prior to handling new grain.

Dispose of any debris removed from bins or machinery as insects may infest it.

Examine area to determine if rodent bait stations are necessary.

Post-binning:

Seal any holes, and caulk around any doors.

Do not seal roof aeration exhaust of inlet vents except during fumigation.

Step 2: Residual insecticide sprays (Table 2).

Pre-binning:

Spray the wall surfaces, ledges, floors, and sills with a residual insecticide.

Spray outside walls and outside base.

For long-term storage (> 1 year) consider fumigating the area beneath the slotted floor. (Table 2 for information regarding insecticides)

Step 3: Condition grain: store clean, dry grain.

Pre-binning:

For long term storage corn moisture should be 15% or less.

Use a grain cleaner to remove cracked kernels and other debris.

Step 4) Proper aeration.

Post-binning:

Run bin fan and stirator to ensure uniform temperatures and prevent moisture buildups. This will reduce mold growth.

Step 5: Use insecticide protectants (Table 2).

Treat grain as it is moved into storage.

Step 6: Regularly inspect grain.

Post-binning:

Monitor the grain regularly. For grain above 55-60°F inspect weekly. For grain below 55°F inspect every two weeks.

Use a grain probe to take samples in a pattern from the surface, and also from the base of the grain mass.

Take samples from the center to the areas near the wall, with samples being no further than 20 feet apart.

“Hot spots” felt on the grain surface or unusual odors are indicators of insect activity, and should be examined.

During the winter insects will move to the center of the bin, so sampling at that location is important.

Step 7: Treating detected infestations when necessary.

Post-binning:

If an insect infestation is detected:Move the grain and retreat as in Step 5. It is possible to kill some of the insects if the grain is moved during cold weather.

Feed the grain to livestock.

Sell at a reduced price

Fumigate (Table 1)

*These precautionary maintenance steps should be taken two weeks prior to binning.

Bin Sampling Safety Protocol

There are many potential hazards associated with sampling inside of a grain bin. For instance, suffocation can occur in grain bins due to bridged grain. Bridged grain is occurs when grain mats together and forms a false floor. When the false floor is broken during sampling procedures cave-ins can occur. Where possible:

Always have another person with a cell-phone outside the bin in case there is a problem.

Wear a harness that is attached to a properly secured rope when entering a grain bin.

Use a pole to break up crusted grain from a distance.

If the grain begins to flow stay near the outer wall of the bin and continue walking and get to the bin ladder as quickly as possible.

Originally posted by South Dakota State University.

You May Also Like