August 31, 2018

Source: North Dakota State University

By Ken Hellevang, NDSU Extension Agricultural Engineer

Harvest timing can have a huge impact on soybean shatter losses and storability. Field losses, splits and cracked seed coats increase as moisture content decreases.

A moisture content of about 13 percent at harvest is optimal for mitigating mechanical damage.

Shatter losses increase significantly when seed moisture falls below 11 percent or when mature beans undergo multiple wetting and drying cycles. Also, molds develop more rapidly in soybeans with seed coat cracks, so the amount of mechanical damage during harvest affects the beans’ deterioration rate.

A moisture content of about 13 percent at harvest is optimal for mitigating mechanical damage.

Harvesting during high humidity, such as early morning, late evening or in damp conditions, may reduce shatter loss and mechanical damage if the soybeans are below 11 percent moisture content. Moisture content can increase several points with an overnight dew or decrease several points during a day with low humidity and windy conditions. Avoid harvesting when beans are driest, such as afternoons.

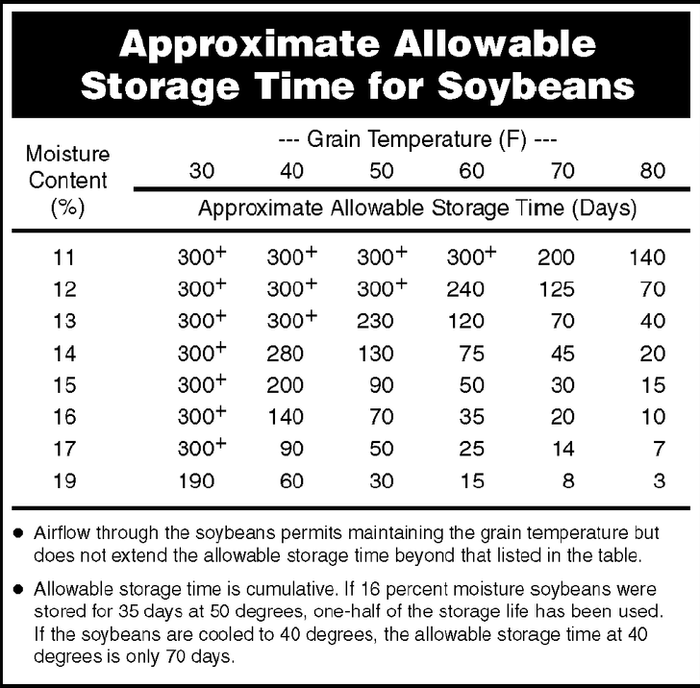

The market moisture for soybeans is 13 percent, which is fine for storing soybeans during cool conditions. If your soybeans will be stored through winter and into the warmer weather of spring and summer, store at 11 percent moisture to limit mold growth and deterioration. The storage life roughly doubles for each percentage point of reduction in moisture content.

Storage temperature

Controlling soybean temperature during storage is critical. Free fatty acid percentages, a negative characteristic, tend to increase with storage moisture, temperature and time.

Store soybeans during the winter near 30 F in northern states and 40 F or lower in southern states.

At 12 percent moisture, free fatty acid percentages increase slowly with storage time if the beans are kept cool. In one study, the average free fatty acid content of 12 percent moisture beans stored at 50 F stayed below 0.75 percent but exceeded this level after only four months when stored at 70 F.

Cool soybeans as they go through the fall and winter to maintain quality. Aerate to keep the soybeans within 10 to 15 degrees of the average outdoor temperature during the fall.

Store soybeans during the winter near 30 F in northern states and 40 F or lower in southern states.

During the spring and summer, aerate stored soybeans to keep the temperature as cool as possible - preferably 40 to 60 F. These temperatures enhance soybeans’ storage life, and reduce mold and insect activity.

Soybeans at 11 percent moisture have similar storage characteristics as wheat or corn at 13.5 to 14 percent moisture. Use an allowable storage time chart for cereal grains to estimate allowable storage times for soybeans.

Storage Recommendations

Keep fans covered. Once soybeans are cooled, cover fan and duct openings to prevent snow or moisture from blowing into the bins during winter storage. Keep fans covered during the spring and summer to limit air from warming the soybeans. Ventilate the top of the bin to reduce solar heating affecting the beans at the top of the bin.

Monitor stored grain regularly. Outside temperature changes can result in temperature and moisture changes inside the bin. Monitor soybeans at least once every two weeks during winter storage and weekly during the fall until the grain has been cooled to winter storage temperatures. Monitor the soybeans weekly during the spring and summer. Measure the grain temperature and watch for indications of problems such as condensation, insect activity and increasing grain temperatures. Record temperature values and grain condition to help track any changes.

Use available tools, but don't turn everything over to automation. Improved technology can help you better manage stored grain, but you still need to manage the grain and inspect it visually. Temperature cables allow you to monitor the stored grain temperature at several locations, and fan controllers can operate fans according to desired air conditions. Monitor and verify that fans are operating as desired.

Equalize soybean moisture content. Soybean moisture variation may lead to storage and marketing losses. Operating an aeration fan will help move moisture from wet to drier beans. Moisture movement will be minimal without aeration airflow. Initially, fans will have to run longer to equalize the moisture content than to cool the grain. The moisture will not be all the same, but it should become more uniform.

For more information, do an internet search for NDSU grain drying and storage.

Originally posted by North Dakota State University.

You May Also Like