With so many variables in play, farmers are always asking their agronomic team questions about practices that will help them obtain optimal yields.

Agronomists and scientists at Beck’s routinely hear three general questions:

How can I improve nitrogen efficiency?

What planter attachments should I consider when upgrading or buying a new planter?

How do I make my spray pass more profitable?

During a summer field day at AgRevival in Gibbon, Minn., Jim Schwartz, Beck’s director of research, agronomy and the company’s Practical Farm Research program, and Jason Gahimer, Beck’s PFR manager, offered the following advice:

N efficiency. Simply put, timing and placement matter, Schwartz said, when it comes to split N applications, anhydrous placement and starter fertilizer rates.

Split applications of N help mitigate risk and make the crop more profitable, he said. Citing four-year multisite research data, 30 units UAN applied 2 by 2 and 160 units UAN sidedress at V3 showed an average increase of $72.36 per acre over the control of 190 units UAN preplant. At 95 units preplant plus 95 units sidedress at V4, corn averaged a $55.88-per-acre increase over the control.

Depth placement of anhydrous preplant is critical, according to Schwartz. Placing a band of ammonia (NH3) 8 inches or deeper, and seven-plus-days preplant is safer for seedlings and provides better yields.

“Depth is key,” he said. “You want it 8 inches or more deep, so moisture expansion doesn’t affect the seedling.”

Schwartz noted that applied N has very little correlation to yield. “We’ve doubled corn yields over the last few decades, while N use has flatlined,” he said, highlighting eight years of Beck’s data that looked at optimal economic N rates. At $6 per bushel corn, 183 pounds N is optimum; at $3 corn, 156 pounds N per acre is suggested.

Schwartz also acknowledged that in 2021, conditions — oxygen, moisture, good temperature and balanced pH — were such that favored soil N mineralization.

“It’s important to understand this,” he said. “It’s a big part of N efficiency. It’s a free gift we need to remember. We might not need that much N.”

Planter attachments. Gahimer said he is often asked what to do first: add aftermarket closing wheels, use planter hydraulic downforce or apply starter on both sides of the row (2 by 2 by 2).

He first recommended closing wheels. Either poly or cast aftermarket closing wheels will help with better seed-to-soil contact, eliminate air pockets and lead to more uniform seed emergence, he said.

Recommended models, along with their yield increase from company research data, are:

Yetter Poly Twisters, 5.1 bushels

Copperhead Ag Furrow Cruiser, 3.8 bushels

Schaffert Mohawk, 3.6 bushels

Schaffert Zipper, 3.1 bushels

SI Distributing Finger-Till, 2.7 bushels

When comparing manually set planter downforce to automated hydraulic, Gahimer said he would invest in hydraulic, specifically Automatic DeltaForce, which boosted corn yield 3 to 6 bushels per acre when compared to manual settings.

And applying N on both sides of the corn row makes sense to Gahimer. “Why would you put N on one side of the row? You’re going to get preferential root growth,” he said. In Beck’s four-year multisite 2-by-2-by-2 return on investment study, the practice consistently returned $22 to $25 more per acre. Research was conducted with the Yetter Dual 2968 Series or Dual Conceal.

Profitable spray pass. To make your spray pass more profitable, Schwartz advises growers to pay attention to time of day, water conditioning and carrier rate.

“Spraying in the morning is most profitable,” he said. “By spraying at lower temperatures and higher humidity, you get a better response [in corn].” In soybeans, the response is not as dramatic.

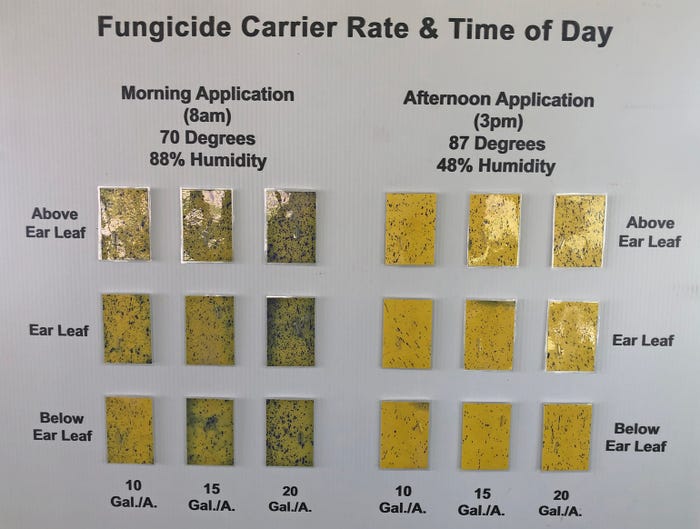

MORNING APPLICATION: Beck’s research finds spraying corn in the morning when temperatures are lower and the humidity is higher improves product coverage, as shown by the dark spots.

Company research compared spraying at 8 a.m. to the control at 3 p.m. and to an 8 p.m. application. The morning application generated the highest yield and profitability. Also, droplet lifespan was increased with cooler, humid weather.

Water conditioning is important since hard water can render spray products ineffective, so Schwartz advises to test your water source. Once you know if you have hard water — which most of the Midwest has — then you should add a water conditioner to change the pH, he said. Make sure you read the label and do not let the conditioner sit overnight in your tank, he added.

And finally, the higher the fungicide carrier rate, the better the coverage. For corn, the return on investment according to Beck’s research shows that a 15- or 20-gallon-per-acre carrier rate is the best. For soybeans, with their denser canopy, 20 gallons is most profitable.

About the Author(s)

You May Also Like