Better-than-expected corn and soybean yields in 2017 in Iowa and nationally added to the largest grain surplus in recent years. With bins holding a large carryover from the big 2016 crop, many farmers and grain buyers had to come up with alternative storage for the 2017 harvest.

“This has resulted in more corn piles, some without cover protection,” notes Charlie Hurburgh, grain handling specialist and director of the Iowa Grain Quality Initiative at Iowa State University. “It has created the risk of corn not being in adequate storage conditions due to lack of aeration and unpredictable weather. Storage bags are also being used to store excess grain. Though storage bags keep the corn covered, there is no aeration and the temperature is set once the bag is filled.”

Long-term storage of 2017 crop likely

With low prices, long-term storage of the 2017 crop well into or through 2018 is likely. “It’s important to move grain in temporary storage to market or to covered and aerated storage as soon as possible,” Hurburgh says. “Iowa corn usage is 200 [million] to 240 million bushels per month, which means the temporary storage should be emptied by January or February at the latest.”

Regions of the U.S. to the north and west of Iowa are converting small-grain acres (wheat or barley) to corn and have higher amounts of grain in outdoor storage than Corn Belt states. The significance of the gradual growth in short-term storage is that corn in bags, outdoor bunkers and piles in machine sheds uses its shelf life faster than corn in well-managed aerated and covered storage.

Weather big factor affecting grain

The U.S. Drought Monitor reached the severe level in early August across much of the major growing area in the western Corn Belt, and the extreme level in a four-county area of south-central Iowa. Dry conditions peaked Aug. 5-10. An abrupt change in weather patterns in mid-August to moderate temperatures and wet weather extended the growing season. This improved grain fill and quality of both corn and soybeans. With extended growth, harvest moistures were higher and field drydown was slower than expected as of mid-August. Grain quality was quite good; quality is normally determined by conditions at the end of the growing season.

Hurburgh has been following public variety trials in Iowa for the past nine years for corn and soybeans, which provides additional information on crop quality, including:

• Corn quality and yield data on corn hybrids planted in strip trials across Iowa in 2017 showed interesting results. Yields were near the highs of 2016, and test weights were excellent. Moisture was somewhat above average. Composition was good as indicated by above-average protein content. Higher yields typically have reduced protein, density and test weight; that trend was not the case in 2017, likely because of favorable grain filling weather.

Kernel fill, as measured by dry weight per kernel, was 5% to 10% above normal, which accounts for the season-long underestimation of yields. Preharvest yield estimates made by USDA during the growing season use five-year average weights per kernel, Hurburgh says.

Corn from the 2017 crop is above the long-term average in feed value, and likely will have slightly lower ethanol yield per bushel. The high test weight will create good storability. This is good corn to use for rotating the stock of 2016 crop that is still in storage.

• Soybean quality and yield data from varieties grown in strip trials across Iowa give an idea of quality and storability of the 2017 bean crop.

Yields weren’t as high as in the previous three years. The processing value, measured by the total of protein and oil, was somewhat below average, Hurburgh says. Processors should be able to make soybean meal that’s close to 47% protein content, although meal quantities per bushel will be down. “On a nationwide basis, we are seeing larger-than-normal variations in soybean protein and oil from north (lower) to south (higher). These will affect processor economics through meal and oil yields,” he adds.

Soybean seed size is smaller than it would have been without the dry June-July. There was late growth of weeds, because rows didn’t fully cover in many cases. You can expect foreign material levels to be higher than the normal 0.5% to 1.0% due to more weed seeds and related material.

Aeration for corn, beans

For corn, high test weights and good kernel fill should reduce grain storage problems, Hurburgh says. This is fortunate since long-term storage is likely with the current crop surpluses. The long run of low humidity conditions in late October and early November created low dew points and good opportunities to cool the grain down by running fans on corn and beans in bins.

Any grain in aerated storage should be at 35 degrees F or below, he says. Unaerated temporary (pile) storage is still at temperature risk, depending on the grain temperature going into the pile. Piles filled from trucks as they came from the field will have more varying temperature and moisture conditions throughout the pile; aeration is the only way to even that out.

If grain is uniformly cool below 35 degrees, it isn’t necessary to run fans continuously, Hurburgh says. Excessive aeration creates weight shrink if grain dries below the market standard moisture level (typically 15% for corn, 13% for soybeans). At today’s low prices and thin margins, losses from excess energy cost and unnecessary shrink can be significant. Removal by aeration of 1% extra moisture in corn will cost about 4 cents per bushel in weight loss and about 2 cents per bushel in energy cost. For soybeans, the cost would be about 12 cents per bushel for the weight and 2 cents per bushel for the energy.

Temperature monitoring

The key to managing grain is effective and consistent temperature monitoring, Hurburgh says. For bin sizes over 20,000 bushels, some form of electronic temperature system should be used. Manual monitoring is progressively less accurate as bin size goes up. An increase in stored grain temperature of 3 degrees in two weeks, if fans haven’t been run in that period, indicates spoilage is occurring somewhere in the bin.

Grain that is spoiling gives off carbon dioxide, he explains. Relatively inexpensive CO₂ monitors can be used to track changes in CO₂ levels, either at fan exhaust or in headspaces. An increase in CO₂ (over a baseline established when a bin is filled) is actually a more sensitive indicator of spoilage than is a rise in temperature. Neither one will pinpoint the location of the trouble in the bin, although temperature sensing cables, common at elevators, will give more hotspot location information than will a general rise in CO₂ levels.

Avoid mixing old grain with new

The significant amount of carryover grain has created situations where 2016 and 2017 grain was mixed in the same bin. Hurburgh advises against such mixing.

“Mixing of old grain that has partially used its storage life with new grain that is not yet stable is likely to create storage problems,” he warns. “The best plan is to either rotate the new grain for the old, or to combine lots of old crop together so the new crop can start an empty bin. In other words, remove the old grain from bins and put it all together in another bin or bins. And put only the new grain in the empty bins.”

Granted, these strategies create extra work at harvest, but that work will pay back if grain is to be stored into next summer or longer, Hurburgh says. “Keep in mind that any crop year mixtures should be the first grain out with fresh sales. If you’ve mixed 2016 grain with 2017 in a bin, that mixed grain is the first grain to sell.”

Final bit of good advice

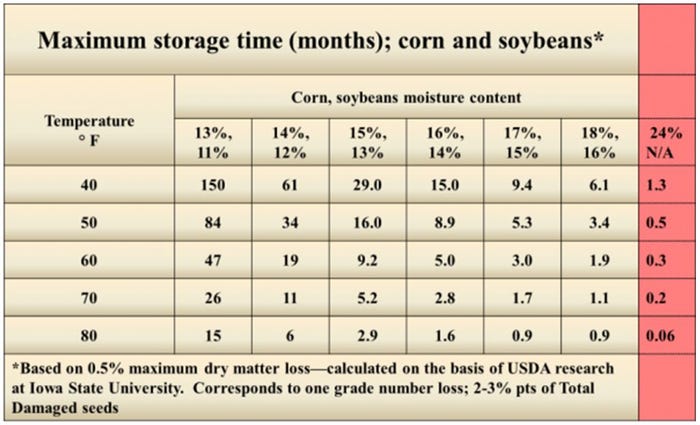

“The shelf life of grain (shown in the table below) needs to be respected especially in conditions of long-term storage,” Hurburgh says. “The storage time is progressively used at the various storage conditions through the year. If wet corn is held before drying, significant percentages of the storage time can be consumed, leaving less for the summer months. In 2016, for example, there were poor cooling conditions: high dewpoints. A lot of the storage life was used up. There were many reports of grain spoilage from blue-eye mold in July and August. In years when you have surplus grain with long-term storage likely, don’t waste the storage life of your grain in the fall; it cannot be recovered.”

For more information on managing stored grain, visit extension.iastate.edu/grain.

About the Author(s)

You May Also Like