April 6, 2015

Anyone who has ever worked on equipment knows bearings can be a lot of work. First off, there are a lot of them. And on agricultural equipment, most bearings must be lubricated periodically to prevent them from wearing or seizing. But over the years, with a lot of sweat and engineering, bearings have advanced to where most of the time, you don’t even know they’re there.

The purpose of bearings is to support rotating machinery, shafts and components. Examples include the wheels on tractors, rolls on hay balers, disks on tillage equipment and gears in a transmission.

On farm machinery, bearings can be smaller than a dime or as large as a dinner plate, and they cost anywhere from a dollar to hundreds of dollars. Bearings come in at least six different types, but most common on farm equipment are rolling element bearings and plain bearings, or bushings.

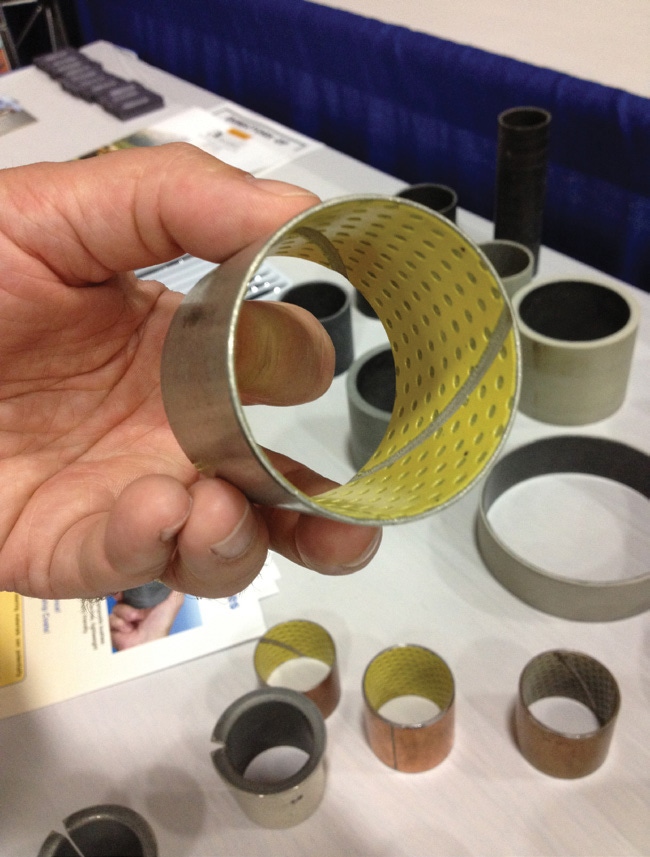

Peer Bearing Co. makes rolling element bearings like these for agricultural applications.

Rolling element bearings gained popularity in farm machinery in the early 1900s, though the concept originated in the 15th century, says Jordan Gutowski, application engineering manager with

Peer Bearing Co., an OEM supplier of these bearings. Gutowski says over the years, rolling element bearings for use in ag applications have become more reliable, more consistent and, recently, maintenance-free.

“The basic seal technology offered in rolling element bearings has been

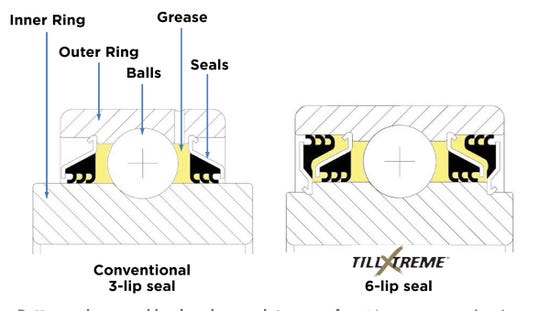

available for over 40 years,” Gutowski says. “What our company has done is improve those seals to give the bearings more longevity in ag applications with high exposure to dust, soil, crop, moisture, etc.” (see diagram).

For example, the company’s most recent line of bearings, called TillXtreme and used in tillage equipment, is made with a six-lip seal (three lips is traditional), in which each lip, or layer, forms another barrier to keep out dirt.

This design allows for long bearing life without the need for frequent greasing. The company also manufactures bearings to fit on hex or square shafts that allow them to be installed or removed without bearing pullers (see photo).

“Over the last five to 10 years, we’ve also seen the need for larger bearings designed to last longer under higher loads and speeds,” Gutowski says.

So the next time you think about bearings, know that a lot of design work has gone into them to make them seem ubiquitous.

Editor’s note: This article is the first of a series looking at essential components that make farm machinery work.

Rolling element bearings in use

Ball bearings or roller bearings can be found in the following applications:

Ball bearings

Tillage: disk bearings/gang shafts, rolling baskets

Planters and grain drills: gauge wheels, openers, closing wheels, seed meters

Balers and mower-conditioners: pickup, drive/idler rolls, conditioner rolls

Combines: Header, feederhouse, augers, etc.

Other general locations: idler sprockets and pulleys, small tractor/mower transaxles

Tapered roller bearings

Tractors and combines: transmission, differential, axle, wheels

Other general locations: nondriven implement wheels

Types of bearings

Bearings come in six different types, named for how they carry the load after their principle of operation. Typically only the first two types are used in farm equipment.

Plain bearing: named for its style (also bushing, journal bearing, sleeve bearing, rifle bearing)

Rolling element bearing: load supported by a ball or roller (also ball bearing, roller bearing)

Jewel bearing: related to jewels in things like old-fashioned mechanical watches in which the load is carried by rolling the axle slightly off-center

Fluid bearing: load carried by a gas or liquid

Magnetic bearing: load carried by a magnetic field

Flexure bearing: supports loads made from plastic or a similar flexible material

Better seals are making bearings maintenance-free. This cross-section of two bearings shows a conventional three-lip seal design on the left and a patent-pending six-lip seal by Peer Bearing Co. on the right. Each lip is an additional barrier to prevent dirt from reaching the balls and raceways, thereby eliminating the need to add grease. For more information about Peer’s new line of tillage bearings called TillXtreme.

About the Author(s)

You May Also Like