November 22, 2018

Anyone who follows new products knows that companies specializing in fertilizer and lime spreading equipment are adapting precision technology. You can buy a spreader that will distribute product up to 120 feet and vary the rate! You can make the change on the go from the cab. Section control is no longer just for sprayer booms — it’s come to dry spreaders, too.

A century ago, farmers had never heard of “precision farming.” The tractor was still a crude power source vying for competition with the horse. But farmers knew soils needed lime applied every so often. And engineers resorted to ingenious ways to help them spread it.

If you stumble across an Oliver Superior sower or an Oliver lime sower stuck in the back of a shed, it may look like a wooden contraption with steel wheels that belongs in Pioneer Village at the Indiana State Fair. There was more technology in those implements than first meets the eye.

Talk about variable rate; literature for the Oliver Superior No. 1 8-foot fertilizer sower says you could spread from as low as 160 pounds to as high as 2,700 pounds per acre. With special feeders, you could extend the range to from 60 to 5,400 pounds per acre. The literature boasts that “75 quantity changes are at the operator’s fingertips.” However, fingertips may be relative. It’s talking “get off and touch the lever” fingertip control.

Engineering feat

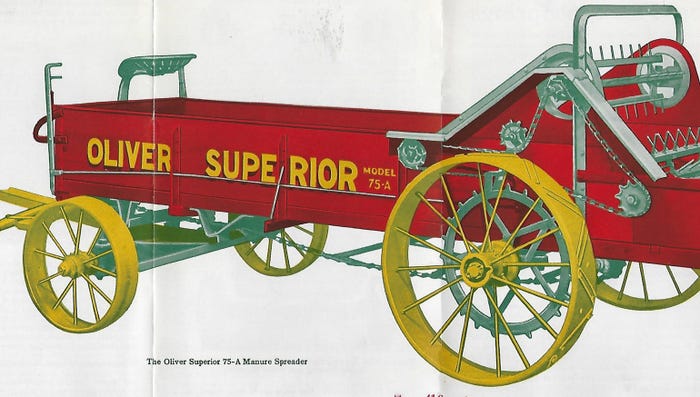

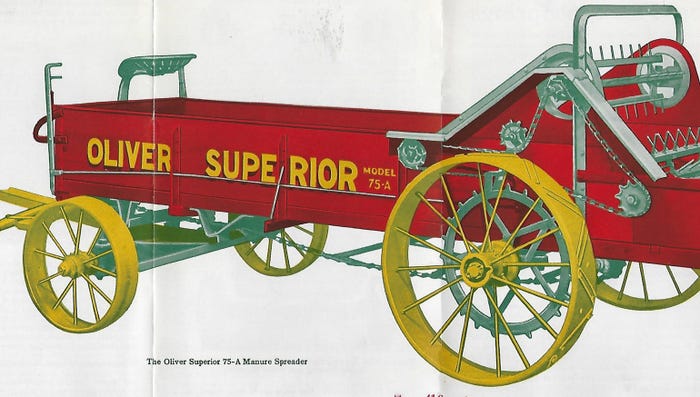

That’s not the most ingenious Oliver invention. The Oliver Superior manure spreader was considered top-of-the-line. Oliver’s Hart-Parr Division in Charles City, Iowa, made tractors, but many manure spreaders were still pulled by horses.

CLASS OF ITS OWN: Oliver was proud of this horse-drawn Superior manure spreader, even before engineers figured out they could convert it into a lime spreader.

CLASS OF ITS OWN: Oliver was proud of this horse-drawn Superior manure spreader, even before engineers figured out they could convert it into a lime spreader.

The machine was known for even spreading. So why couldn’t it spread other materials? An enterprising engineer set out to convert it into a lime spreader. After all, it could hold a large quantity of lime in the spreader box.

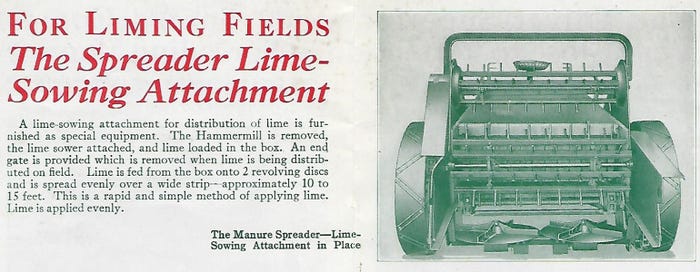

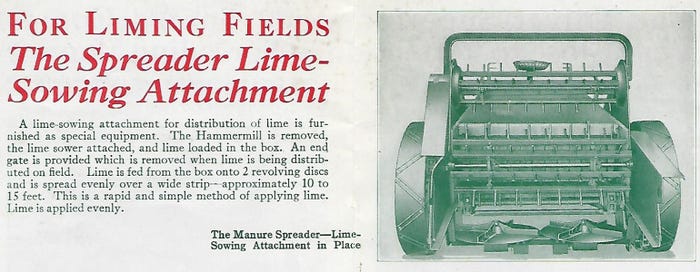

How was he going to spread it? He would use a double-spinner — a crude ancestor of double-spinners, which have been the mainstay of the industry until now.

Engineers removed the hammermill, which was the most rearward beater — the one with metal flails — and replaced it with a flat double-spinner. Lime fed from the box and dropped onto the two revolving discs, driven by the same mechanism that drove the hammermill.

Spreading width was estimated at 10 to 15 feet. But the literature insists that the lime was applied evenly.

When the farmer finished spreading lime, he could remove the double-disc spinner attachment and reinstall the hammermill. He was ready to spread manure again.

Don’t believe it? Check out the picture below. The tools of a century ago may have been crude, but human ingenuity was as sharp as it is today!

INNOVATIVE INVENTION: Who knew? You could spread lime with a manure spreader a century ago if you had the right attachment.

Comments? Email [email protected].

You May Also Like