March 7, 2019

The 1950s, ’60s and ’70s were transition times in American agriculture, especially in handling corn. Picking on the ear with mounted, pull-type and even Massey-Harris self-propelled corn pickers gave way to shelling with a self-propelled combine. Ear corn cribs made way for grain bins.

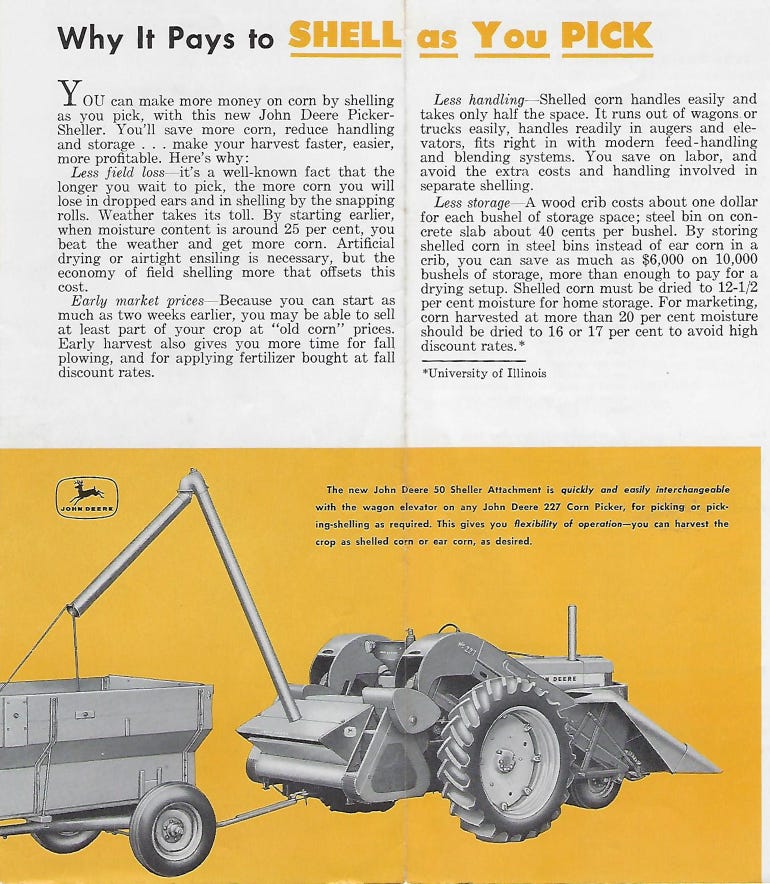

The transition didn’t happen overnight. Smaller operations with dairy or beef cattle held on to corn pickers and cribs longer. Machinery companies sensed a need for farmers who still wanted a corn picker, but who also wanted to shell corn once cribs were full. That’s when John Deere introduced the sheller attachment for its famous John Deere No. 227 two-row mounted corn picker.

I purchased literature recently, and in the bundle of authentic booklets were three pieces related to John Deere corn pickers and the sheller attachment. It brought back memories. We had a John Deere mounted picker when I was growing up on a small dairy farm.

Enter the sheller

Our farm fit into the category the equipment makers were targeting. Dad wanted ear corn for dairy feed. But once the 3,000 bushels of crib space was full, he wanted to sell the rest. He didn’t own a self-propelled combine then, so that meant waiting for a custom harvester.

He found a used John Deere sheller attachment. Messing with mounted corn pickers was a pain, but switching from picking to shelling was much easier because the main harvesting unit stayed on the tractor. The elevator attachment switched out for the sheller. Ears fell into a sheller bed instead of an elevator. We had gravity wagon loads of shelled corn we could haul to the elevator.

THE ‘WAY BACK’ MACHINE: This image even predates me. When I was a kid, we shelled into gravity wagons, not flare-bed wagons, as I recall.

Eventually Dad quit milking and sold the cows. He bought a Gleaner K2 combine, and we no longer needed the picker or sheller. But for the few years we did, it was a great option for a farmer who hadn’t totally converted to shelled corn.

1950s logic

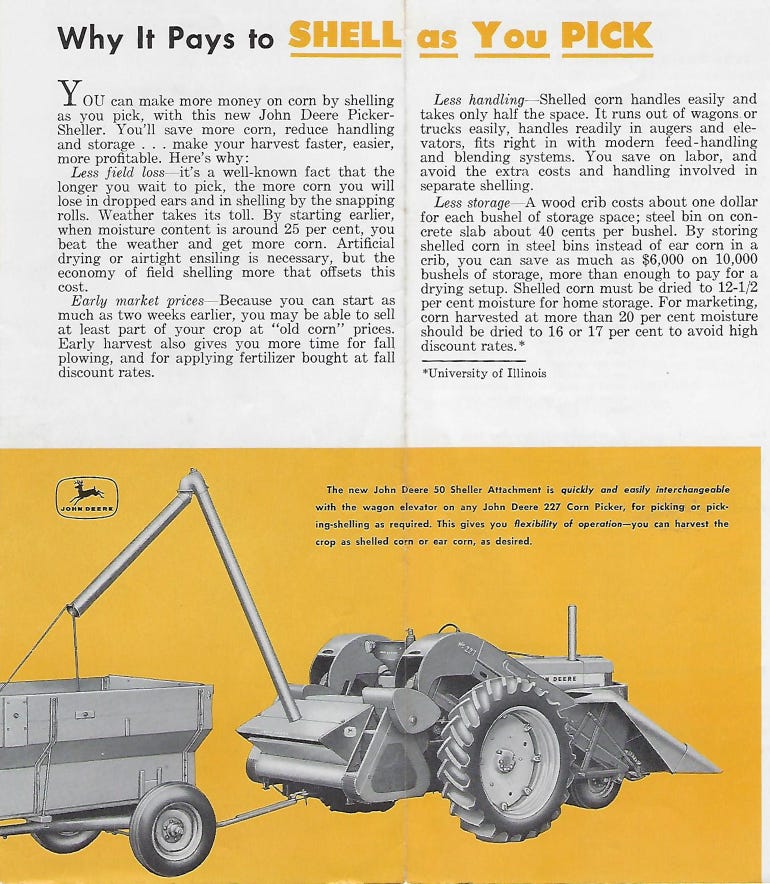

A 1950s brochure for the 227 picker and “new” No. 50 sheller attachment devoted considerable space to convincing the would-be customer why it made sense to shell part of his corn instead of crib it all and shell it later. A neighbor still used an old Minneapolis-Moline stationary corn sheller to shell off excess ear corn every spring.

In 2019 American agriculture, this section from the brochure quickly dates itself. The goal of the following paragraphs was to convince the customer that a sheller attachment reduced storage needs and costs.

“Less storage: A wood crib costs about $1 for each bushel of storage space; a steel bin on concrete slab about 40 cents per bushel.

“By storing shelled corn in steel bins instead of ear corn in cribs, you can save as much as $6,000 on 10,000 bushels of storage, more than enough to pay for a drying setup.

“Shelled corn must be dried to 12.5% moisture for home storage. For marketing, corn harvested at more than 20% moisture should be dried to 16% or 17% to avoid high discount rates.” At least, that’s what the University of Illinois recommended, the brochure notes.

Comments? Email [email protected].

You May Also Like