Today's quarter scale tractors are starting to look more like today's full-size tractors – at least when they're built by the University of Nebraska-Lincoln's quarter scale tractor team. This year, UNL's A Team took first place overall at the International Quarter Scale Tractor Competition in Peoria, Ill., and the modern technologies, innovations and amenities incorporated on this year's design had a lot to do with it.

CONTINUOUS IMPROVEMENT: Hoy (left) and Luck with this year's quarter scale tractor design, which borrows from several successful components of the 2014 and 2015 designs. "If you scrap the whole design and start clean, you don't get where you want to be," Hoy says. "That's kind of how it works in the real world. About 80% of the design is borrowed from previous years."

"The competition has been going on for 19 years, and this is the first time Nebraska has won it all," says Roger Hoy, UNL biological systems engineering professor and director of the Nebraska Tractor Test Lab. "They said, 'this team accomplished something no team has ever done.' We set a record by improving 22 places in one year."

The design for this year borrows from several successful components of the 2014 and 2015 designs. The build is about constant improvement – that is, building upon successful designs.

Building for continuous improvement

That's where the idea for this year's build's actuator-controlled continuously variable transmission (CVT) came in. "A lot of the technology started out with last year's transmission. Last year, it wasn't too reliable," says Micah Bolin, UNL senior and Ag Engineering major and one of this year's A Team captains. "We needed to control our CVT. It started with the linear actuator. We chose electricity because of the options available and that's where the industry is going."

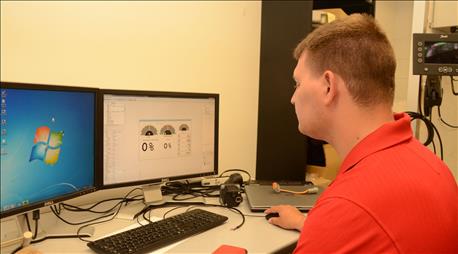

DIGITAL DISPLAY: Lindhorst sits in front of the digital display he designed for this year's tractor. Being a new component to the competition, it took some learning, Lindhorst says. "You can't just do something and expect it to work – you've got work out the bugs," he says. "Picking out the tricks and making things work smoothly is something you need to experience for yourself."

A CVT changes gear ratio based on centripetal force, so it needs high RPMs. But the Briggs and Stratton engines on quarter-scale tractors spin at only 3,600 RPMs. The linear actuator overrides the CVT's natural instinct to shift in and out of gears when it shouldn't be.

Caleb Lindhorst, an Ag Engineering major who will be graduating in December 2016, was the architect behind the touch screen.

~~~PAGE_BREAK_HERE~~~

"Since everything is going to digital, it's much easier to show it on the screen than using manual gauges. Other teams had screens like this, but we were the first to have a touch screen. This is one thing I've very passionate about," Lindhorst says. "You can read the speed of the tractor, the RPMs, the temperatures, anything to do with the CVT and transmission – the gear ratios that the CVT is at. We can take that information and load it on a flash drive."

COMPETITIVE BUILD: Team captain Ryan Hanousek operating UNL's quarter scale tractor during the pulling event at the competition on June 2-5 at Peoria. Photo credit: John Lumkes, associate professor agricultural and biological engineering at Purdue University.

Taking advantage of extra prep time

What also made a big difference this year was the amount of preparation that went into the competition. Both the A Team and X Team finished in record time – by Christmas break in 2015. This gave them extra time to test and fine-tune the tractor. This year's team built their own pulling cart to use on the test lab's track and their own maneuverability course to prep for the competition. They also took a trip to Case IH's factory in Grand Island to get industry input from some of the company's engineers.

Joe Luck, UNL biological systems engineering assistant professor says what set this year's team apart was the emphasis on not just building a top-notch tractor, but building a top-notch team that could compete. At the competition, students and tractors are judged for design, including factors like ergonomics, safety, and serviceability. But there are also competitions for maneuverability and pulling, as well as a written report and oral report to discuss details like cost structure, design, and marketing.

"The captains this year looked at the whole competition as their challenge. It wasn't just building a cool tractor. This group started designing the tractor over summer break after last year's competition," Luck says. And that culture is now instilled in this year's X Team – which will be next year's A Team. "That's the exciting part – you have this young group that's seen what it takes to be as competitive as possible."

Learn more in an upcoming print version of Nebraska Farmer.

About the Author(s)

You May Also Like