December 28, 2017

By Brian Velde

A method for watering and fertilizing crops from underground is being demonstrated for the first time on field crops in Minnesota.

Subsurface drip irrigation could save water, improve nitrogen use and boost yields.

SDI delivers water and nutrients directly to the root zone through buried tubes. Because crops are watered from belowground, there is no loss from evaporation, runoff or wind drift. That cuts water usage by up to one-third.

Proponents say SDI offers more uniform water and fertilizer application than overhead irrigation, resulting in more consistent growth and higher average yields. In addition, the soil surface stays dry, which cuts weed seed germination. SDI is also an efficient way to irrigate odd-shaped fields where center-pivot irrigation isn’t practical. And it covers the entire field, so there are no dry corners.

My father, Alan Velde, and I are collaborating with University of Minnesota researchers to test this irrigation method on our farm in Yellow Medicine County, Minn. The three-year project will compare drip irrigation and fertigation with conventional dryland management in a 60-acre continuous corn field. The research is sponsored by the Minnesota Corn Growers Association Research and Promotion Council.

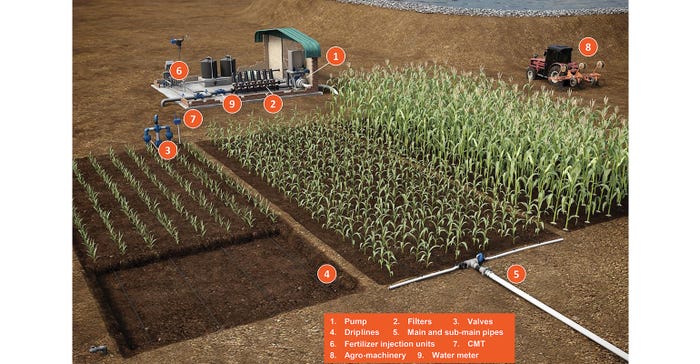

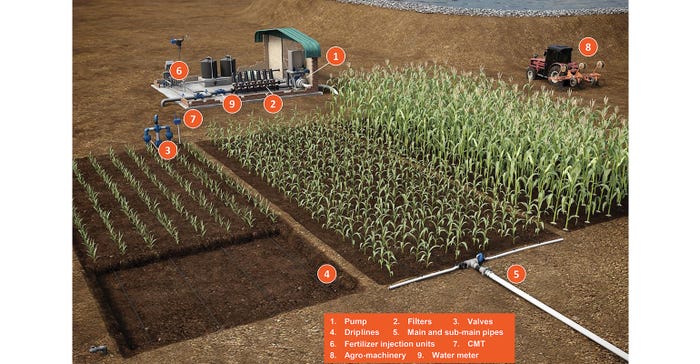

HOW IT FLOWS: Subsurface drip irrigation consists of flexible, polyethylene tubes with water emitters welded to the inside walls of the tubes at set intervals. The tubes, or drip lines, are buried in the field in rows 40 to 60 inches apart and 12 to 18 inches deep. (Photo by Liz Morrison)

New in the Midwest

SDI consists of flexible, polyethylene tubes with water emitters welded to the inside walls of the tubes at set intervals. The tubes, or drip lines, are buried in the field in rows 40 to 60 inches apart and 12 to 18 inches deep.

Water is pumped at low pressure (10 to 25 psi) from the source through a water filtering system and into the drip tubes. The emitters, which are calibrated with pressure regulators to deliver uniform flow throughout the field, slowly discharge specific amounts of water directly to the root zone.

Growers must control rodents to protect the buried drip lines. It’s also necessary to flush the lines annually to remove accumulated debris, and to drain the pipes each year before freeze-up.

“This is an active management system to make it work right,” says U-M soil scientist Jeff Strock, one of the research collaborators.

Subsurface drip irrigation is not a new technology. It’s been used for decades on high-value vegetable crops. In the 1990s, as SDI equipment improved, farmers in the dry Southern Plains began using drip irrigation instead of center-pivot or flood irrigation to grow corn and cotton.

However, SDI is new to the Midwest, where it has been little-studied. Two of the questions we have about it are:

• What is the yield response on different soil types?

• How long would it take to pay for the system on different soil types?

MAIN LINES: Main lines distribute water to the drip tapes. (Photo by Liz Morrison)

To help answer these questions, we divided our test field into six productivity zones. Our SDI system allows us to manage water by zone.

In the most productive zones, we expect to raise 240 bushel per acre corn in a good year. We wanted to know if SDI could bring those yields up to 300 bushels per acre. It takes about 30 inches of water to grow 300-bushel corn. In western Minnesota, we typically get about 25 inches.

The test field also has a large sand vein, where we typically get very low yields — not enough to cover our input expenses in most years. In these zones, we expect SDI to boost yields significantly.

How it works on our farm

Our farm’s SDI system was installed last spring by NutraDrip, a Kansas-based irrigation company. Seven-eighths-inch drip tape lines were placed 14 inches deep and 60 inches apart, running north to south across the full length of the field. We plant using RTK guidance, so every row of plants is 15 inches from a drip line. The drip lines have water emitters every 27 inches — except in the sandy zone, where emitters are spaced every 20 inches.

THE SYSTEM: This graphic shows how subsurface drip irrigation delivers water and nutrients directly to the root zone through buried tubes. The method, which is new for Midwest row crops, is being tested on a farm in Yellow Medicine County. (Source: Netafim)

Three 60-foot-wide, unirrigated check strips were left within the field to allow dryland yield comparisons. Installation took a day and a half.

Four and 6-inch main lines distribute water to the drip tapes. Drip systems require 2 to 5 gallons per minute per acre to effectively irrigate a crop. Our system is set up for 3.3 gallons per minute per acre, which will apply one inch of water every 5.6 days over 60 acres.

Our irrigation water is pumped from the Yellow Medicine River, where a 10-horsepower pontoon pump delivers 250 gallons per minute. Our DNR permit allows us to withdraw 9.6 million gallons — enough for 6 inches of water averaged over the 60-acre field. The river water runs through a sand filter to remove silt before being distributed to the field.

In 2017, we irrigated corn from the V-11 growth stage through tasseling. From July 4 to Aug. 2, we applied between 3 and 7 inches of water, depending on the productivity zone. We monitored soil moisture with 48-inch soil moisture probes placed about 10 inches to the side of the drip lines.

We applied the majority of our nitrogen preplant, and added 60 pounds of N in-season through the drip system based on weekly tissue samples. Next season, we plan to apply a larger portion of N in-season.

Yield and ROI

Our SDI system cost $1,950 per acre, which is slightly higher than a center-pivot system. It is expected to last about 25 years.

If we can boost our average yield on the field by 84 bushels per acre, we can pay for the system in five years. The study will continue through 2019.

Velde is a Wood Lake, Minn., farmer and certified crop adviser for Centrol. Find information and links to Minnesota CCAs at mcpr-cca.org.

You May Also Like