Expect herbicides to cost more this year, with some hard to find. How can you still ensure top performance from every dollar spent on herbicides?

Fred Whitford, director of Purdue Pesticide Programs, assembled a series of helpful publications. Here’s a brief look at three key areas. For details, access publications online.

1. Focus on water quality. Check out The Impact of Water Quality on Pesticide Performance, PPP-086. Most ground-applied spray solutions are 99% water, and herbicide performance is tied to water quality.

Water hardness and water pH are key factors. If water is too hard, containing lots of dissolved minerals, it can reduce pesticide performance. The best example is glyphosate.

Likewise, if water pH doesn’t match label recommendations, active ingredients may not function correctly. This is the case for some insecticides, Whitford says. For many herbicides, something should be added to typical Indiana water to reduce pH. Research trials often show an economic return for adding water-conditioning agents.

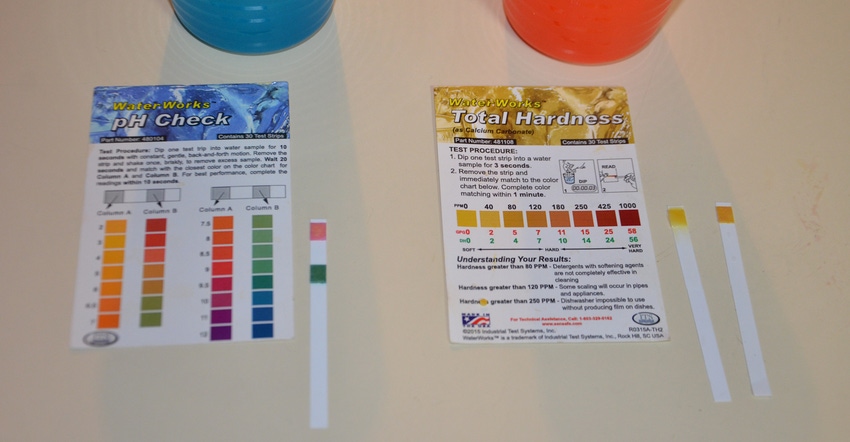

The first step is testing your water for hardness and pH, Whitford says. Test strips used by Indiana Prairie Farmer for demonstration shown in the photo were obtained from Industrial Test Systems Inc.

2. Focus on water temperature. The publication Water Temperature and Herbicide Performance, PPP-112, indicates it pays to avoid using very cool water in spray solutions. Purdue weed control specialists found that spraying with water at 41 degrees F reduced weed control for certain weeds with all four herbicides tested.

They looked at 2,4-D choline (Enlist One), glufosinate (Liberty), mesotrione (Callisto) and glyphosate plus dicamba in a premix. The products performed properly on all weeds at 72 and 102 degrees.

Performance slipped for all four products at 133 degrees as well.

The group reached two conclusions, Whitford says. First, use water warmer than 41 degrees if you’re spraying in early spring. Second, monitor temperature of water stored in aboveground tanks. Color of the tank didn’t have much effect on water temperature.

3. Focus on adjuvants. Compendium of Herbicide Adjuvants, PPP-115, provides a place to start, Whitford says. This edition was prepared in 2016. Adjuvants have been added and removed since then.

The best advice is to follow recommendations for adjuvants on current herbicide labels, Whitford says. For example, ammonium sulfate, a common adjuvant, can’t be used with dicamba soybean herbicides. That is stated clearly on current product labels.

To learn more about adjuvants and review how water quality affects performance, check out PPP-107, Adjuvants and the Power of the Spray Droplet: Improving the Performance of Pesticide Applications. This resource explains how spray droplets must enter plants through leaves for herbicides to work. It emphasizes that preventing minerals from tying up active ingredients is one key function for adjuvants.

PPP-107 provides more details on 13 categories of adjuvants. These include water-conditioning agents, surfactants or wetter-spreaders, oil concentrates, evaporation retardants known as humectants, ammonium fertilizer solutions, compatibility agents, defoamers and anti-foamers, scents or masking agents, marking agents, stickers, pH adjustors including acidifiers and buffers, and drift-suppressing agents or deposition and retention aids.

About the Author(s)

You May Also Like