(This article has been updated to reflect the USDA's deregulation of the Enlist cotton trait in the U.S.)

Mississippi cotton growers can look forward to more tools for weed and insect control from new technologies that have been in trials for several years and are now moving toward commercialization.

In most cases, Mississippi Extension and research specialists say, they have been working with these technologies under confidentiality agreements and have not been able to discuss them with growers until now.

Growers got a firsthand look at some of these products at a recent Mississippi State University technology field day held at the R.R. Foil Plant Science Research Center at Starkville.

Stay current on what’s happening in Mid-South agriculture: Subscribe to Delta Farm Press Daily.

One of those technologies — Bollgard II XtendFlex cotton, a triple stack variety from Monsanto with tolerance to dicamba, glyphosate, and glufosinate herbicides — is estimated to be planted on 750,000 acres across the cotton belt this year, says Darrin Dodds, Mississippi State University associate Extension/research professor of plant and soil sciences.

The USDA's APHIS had deregulated the Xtend trait in time for a significant acreage of the cotton to be planted, but approval for over-the-top application of dicamba is still pending and the herbicide cannot legally be used on the cotton this year. It is expected that registration will be granted in time for the 2016 season.

Tolerance to three unique modes of action in the Xtend system will provide added choice and flexibility to apply multiple combinations of these three herbicides pre- and/or post-plant for a very effective weed management system, Dodds says.

The Enlist Weed Control System from Dow AgroSciences builds on the Roundup Ready system by incorporating tolerance to a new 2,4-D formulation.

Enlist Duo herbicide combines two proven products, glyphosate and a new 2,4-D, aimed at tough yield-robbing broadleaf weeds — including resistant and hard-to-control species in corn, soybeans, and cotton. Tolerance to 2,4-D means fewer plant-back restrictions; growers can plant Enlist crops immediately after applying 2,4-D for burndown.

The USDA announced July 23 that it had deregulated the Enlist cotton trait in the U.S.

Usage, application requirements noted

To use either Xtend or Enlist technologies, he notes, growers will have to complete an online training module, which is expected to be available this fall from Mississippi State University.

Growers got a firsthand look at new cotton technologies at the recent Mississippi State University crops technology field day.

“Also, when applying these materials, it will be important to use specific spray tips and boom height,” Dodds says. And applications cannot be made in winds exceeding 10 mph. Growers will also need to carry out “a rigorous cleanliness regime for tanks, hoses, etc. The label will have the final word on these requirements.”

He also cautions: “Keep in mind that Xtend and Enlist are two different chemistries — they are not interchangeable.”

Pigweed (Palmer amaranth) is “the driving factor in weed control today,” said Jason Bond, Extension/research professor at the Delta Research and Extension Center, Stoneville.

But, he says, there are now nine confirmed glyphosate-resistant weed species in Mississippi — more than any other state.

“Palmer amaranth is more concentrated in the Delta,” Bond notes, “but there is no area of the state that doesn’t have some of it. Water hemp is another weed that we can pretty much assume is glyphosate-resistant. If these weeds are in your county or surrounding counties, the way these species move it’s likely you will sooner or later have resistance. We’re not recommending any weed management program that doesn’t include both preemerge and postemerge herbicides."

“These new systems, Xtend and Enlist, will be added to our MSU recommendations. The nuts and bolts of our weed control recommendations will remain the same — with variations according to your choice of technology.”

Since the advent of Bt cotton, Jeff Gore said, registrations have stipulated that companies must continue developing the technology in order to avoid resistance and improve efficacy against pests. “So, companies are continuing to add other genes in the mix to manage resistance.

“The real value of all Bt cotton has been tobacco budworm control,” says Gore, MSU associate professor of entomology and plant pathology. “Bollgard I represented a huge advance over non-Bt cotton. Bollgard II added more options. The third generation of Bt cotton is not as big an improvement as Bollgard II was over Bollgard I, but in tobacco budworm country, it is valuable from a resistance management standpoint, and growers will welcome this new technology.”

Plant bug gene also controls thrips

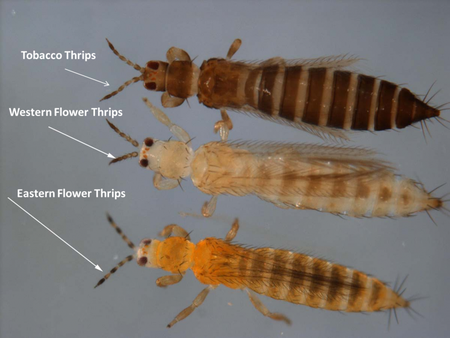

Another technology in the pipeline is cotton with a gene for plant bug control. While that in itself may not have been enough to warrant commercialization, says Gore, there was a surprising corollary benefit that could result in the technology coming to market — thrips control.

An unexpected benefit of cotton with a gene for plant bug control was finding it also offers thrips control.—Mississippi Crops photo

“We started looking at cotton with the plant bug gene at the Stoneville station about seven years ago,” he says. “We were one of only three Universities in the U.S. to first work with this technology.”

The gene targets both adult and immature plant bugs, he says, but even though it offers effective control, “we probably will still have to spray in areas with high populations, such as the Delta, where growers can now make as many as 10 applications in a season. This technology could very well reduce the number of applications by 50 percent or more.”

Although the plant bug gene might not have been of sufficient demand across the cotton belt to justify its commercialization, Gore says, “We noticed in our research that we were also getting thrips control from this trait. A gene for thrips control is something that could be applicable to almost every cotton acre in the U.S., and would allow the company to recoup their investment. It now looks like Monsanto intends to move forward with this technology.”

Angus Catchot, MSU Extension professor of entomology and plant pathology, said, “I’m super excited about the thrips component, even though it’s still a ways from market. This is a very damaging pest and is consistently a problem every year. The thrips gene cotton, even in unsprayed plots, has looked very, very good.”

Each year, he says, cotton growers in Virginia and North Carolina have very intense thrips pressure. “I pretty much consider Virginia the absolute acid test for thrips control. When I’ve talked with them about it, they tell me this cotton has looked fantastic for thrips control.

“When we lost Temik,” Catchot says, “we then relied almost 100 percent on seed treatments. Now, we’re seeing resistance to thiomethoxam, and in the Mid-South growers have moved almost 100 percent to imidacloprid. But in plots this year, there were indications we’re beginning to see a decline in imidacloprid efficacy as well.

“Neonicotinoid insecticides are under intense scrutiny now by EPA because of pollinator concerns, so this gene technology could really pay off for us in the future as another thrips control option.”

About the Author(s)

You May Also Like