Technology an integral part of farming operations for Seward and Son

With 20,000-plus acres of corn, soybeans, and cotton, and 1.2 million bushels of storage, the Byron and Darrington Seward were early adopters of technology to improve efficiency and yields — they began making variable rate fertilizer applications more than 25 years ago— and they’re constantly on the lookout for ways to further fine-tune their operations that span 350 fields within a 10-mile radius of the town of Louise, Miss.

On a sunny late summer morning, as combines and grain carts move through a corn field miles away, Byron Seward and son Darrington are watching it all on iPad and laptop.

They see icons of the individual pieces of equipment moving down the field rows, and a stream of real-time data: variations in yield, ground speed, moisture content, variety, total pounds thus far harvested from that field, and a host of other parameters related to that crop and location.

While waiting for corn-laden trucks to arrive at the Louise, Miss., storage site, they’re also periodically monitoring a graphical representation of already-harvested corn as it’s moving through the dryer and into bins.

All this at the end of a season that has employed a sophisticated array of electronic technology for variable rate applications of chemicals and fertilizers, precision planting, equipment operation, irrigation control and monitoring, and data collection/analysis.

REAL-TIME MONITORING of combines and other machinery gives the Sewards constant updates on farm machinery via smart phones, tablets, and other devices. Here they see corn yielding 278 bushels, number of pounds harvested thus far in that field, combine speed, variety being harvested, location of the combine in the field, and variations in yield for this particular swath.

With 20,000-plus acres of corn, soybeans, and cotton, and 1.2 million bushels of storage, the Sewards were early adopters of technology to improve efficiency and yields — they began making variable rate fertilizer applications more than 25 years ago and were an early cooperator with Sanders and their precision ag software — and they’re constantly on the lookout for ways to further fine-tune their operations that span 350 fields within a 10-mile radius of the town of Louise.

And they don’t just buy the technology and turn it over to others to run — they immerse themselves in every aspect of the systems, then work with suppliers to develop enhancements based on their experience in actual use of those systems.

“With our large acreage, time and productivity are always key challenges,” says Darrington. “We look for ways to effectively use technology to save time and boost productivity.”

Stay current on what’s happening in Mid-South agriculture: Subscribe to Delta Farm Press Daily.

This year, Seward and Son Planting Company had 5,000 acres of corn, 10,000 acres of soybeans, and 6,000 acres of cotton. The technology they use to plan, plant, manage, and harvest those crops runs the gamut from the latest equipment to high speed telecommunications.

“We have John Deere 24-row planters with Precision Planting systems that adjust each unit for exact planting depth, so everything is uniform across a field, regardless of soil type,” Darrington says. “We had used Precision Planting’s eSet seed metering system for several years, which gave us a very uniform stand in corn, but this year we’ve used Precision Planting’s new vDrive system, which allows us to get exact plant populations row by row.

“We’ve been very impressed with this system and the consistent emergence and development we get. We’re research partners with Monsanto — we plant all Dekalb corn, our soybeans are Asgrow, and our cotton is Deltapine — and we see precision planting technology, along with constantly improving corn hybrids, as a way to push yields even higher in the future.

Consistent planting depth, higher speed

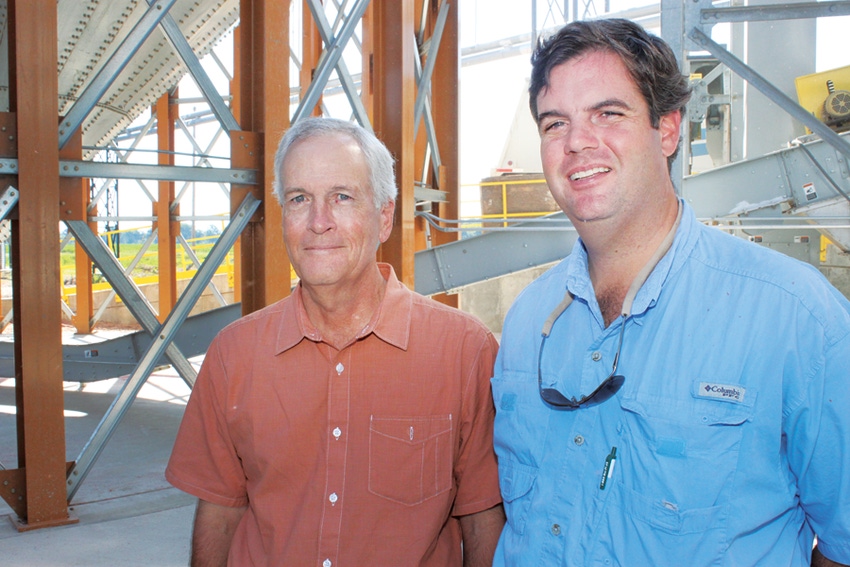

DARRINGTON SEWARD, right, and Vaughn Koehn, Precision Planting LLC, West Point, Miss., monitor corn combining on an iPad.

“We’ve been really impressed with Precision Planting’s DeltaForce down pressure control system,” Darrington says. “Sensors detect different resistance in soil types and instantly make adjustments so planting depth will be consistent — we can get an exact 2-inch placement, row after row, acre after acre. We can attribute a part of our higher yields to this equipment.

“It has also allowed us to increase our planter speed. Before, we were running at 4 to 4-1/2 mph and now we’re comfortably running at 6 mph and still getting optimum seed placement. This increased speed will allow us next year to run only two planters instead of three — an additional cost savings.

“On our cotton land, where we have a lot of variations in soil types, seed placement requires different down force for consistency, and with this equipment we can get exactly the depth we want. The results have been phenomenal.”

Byron says, “We like the remote display access that allows us to see in real time where all our equipment is, how it’s operating, what the yield is, and an extensive array of data that we can use to analyze every factor that influences crop performance and yield. With this technology, there are no secrets — we can see where all of our equipment and trucks are, and how they’re operating.”

CORN DRYING capacity is 100,000 bushels per day. Darrington Seward checks the monitor showing dryer operation.

All the data are stored in a cloud-based service. “We have no servers or desktop software on-farm — everything’s in the digital cloud, and all our software is Internet-based,” Byron says. “We’re fortunate that Delta Telephone Company at Louise has been in the forefront of cellular and digital services, and we’re able to get high speed connections for our systems and devices.

“We have MobileStar virtual dashboards on our 19 tractors, 5 combines, and 4 pickers, allowing us to remotely monitor all functions — oil pressure, temperature, coolant, RPMs, fuel consumption, etc. — and whether a particular piece of equipment is being operated the way we want. This information is updated every second. All the data are stored in the cloud and we can look back six months to see how each piece of equipment performed and what the maintenance issues were.

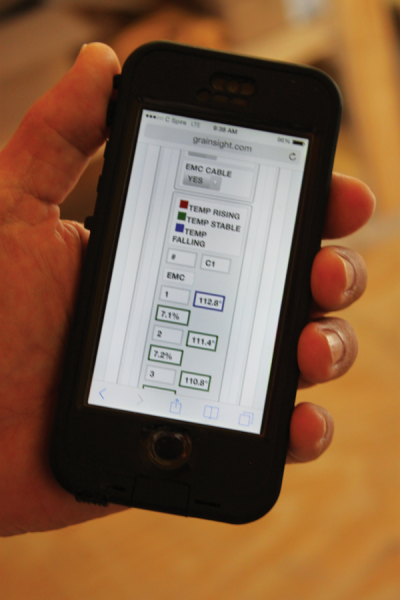

MONITOR shows progress of the grain drying operation.

“I get an e-mail every hour showing me where the harvest stands, and then I get end-of-day totals on everything related to the harvest. We sell our grain based on what the yield monitors tell us while harvest is in progress — that information is what we use to manage our inventory. We market our cotton through Staplcotn and we handle the grain marketing ourselves.”

The Sewards roll over their equipment inventory each year, Darrington says. “We get a multi-unit discount, and we’re running equipment that is under warranty if something goes wrong — even brand new equipment can have expensive problems; we’ve had to replace a combine engine that would’ve cost $100,000. This also provides the dealer with low-hour equipment they can sell to smaller farmers at a more affordable price. We have to order equipment 1-1/2 years in advance, and all the data we maintain on equipment performance helps us in planning our future needs.”

Four John Deere S690 combines were used in harvesting this year’s corn crop. When we have that much corn coming out of the field, it becomes a handling challenge,” Darrington says. “Our storage capacity allows us to handle our harvest volume without having trucks waiting in line somewhere. We can dry 100,000 bushels of corn per day. This also allows us to harvest earlier, at higher moisture levels. The corn we’re harvesting today is at 21-22 percent moisture.

“The continuous flow dryer uses propane fuel, and we’ll probably go through six 10,000-gallon tankfuls in a season. The Zimmerman control system gives a graphic real-time display of drying status, moisture levels, etc. We have 840,000 bushels of storage at this location and we’ll fill them all with this year’s corn, plus truck several hundred thousand bushels out.”

System to monitor grain bin moisture

ON HIS iPHONE or iPad, Byron Seward can check the status of all the farm's grain storage bins.

Delta Telephone Co. is currently installing cables in the bins to monitor humidity in the stored grain, Byron says. “This will allow us to set the target moisture rate we want to maintain, and the system will turn fans on or off to hold that moisture level. We will monitor every bin remotely via iPhone or iPad.”

Last year was “a really strong corn year, with near-ideal weather, despite a late start for planting,” Darrington says. “And this year is going to be even better. Across the board in 2013, our corn yield was about 220 bushels on 4,500 acres. This year, we’ve cut fields in the 260-280 bushel range, and I think we’ll average 225-230 bushels across all our acreage.

“Weather has been good, we’ve had timely rains, and an added factor has been the phenomenally uniform and consistent crop we got with the vSet and Delta Force Precision Planting systems. The technology adds to the overall cost of the planter, but it certainly pays off in increased yields.”

Vaughn Koehn, West Point, Miss., the representative for Precision Planting LLC, says, “The Sewards farm really large acreages, but they still concentrate on getting the highest possible yield from every single acre. They’re extremely detail-oriented and they are very technology-oriented — they know the nuts and bolts of the systems they use and what they want those systems to do for them.”

MASSIVE AMOUNTS of data are generated by all the technology systems in operation on the farm. The Sewards use the data for analysis of equipment performance, costs, maintenance, yields, and other key factors in their 23,000-acre operation.

Byron says, “A lot of people are selling technology nowadays, but a lot of them don’t really support what they sell. When we buy a system, we expect it to be fully supported. We can’t afford to have downtime because something isn’t working as it should and there’s nobody at the company to help. We’ve been pleased with the support we’ve received for our Precision Planting systems.”

The Sewards drill all their soybeans with a John Deere 1990 drill. “With reduced margins because of lower corn prices, I expect we will be seeing more soybeans next year. We averaged 55-60 bushels across the board in 2013, dryland and irrigated, and I think this year will be better — the plants are really loaded with pods.

“This growing season has been cooler, and we’ve had timely rains. We’ve only irrigated corn 1-1/2 times, soybeans two to three times, and cotton twice — that’s only about half the irrigating we’d do in a ‘normal’ year.” And he says, “We still remember the rains of 2009, when we lost 3,000 acres of soybeans.”

Last year brought “the best cotton crop we’ve had in 40 years,” Darrington says. “We averaged three bales per acre across the board; that compares to our long-time 1,100 pound average. We easily got an extra 300-350 pounds last year due to the near ideal growing season.

“This will be our fourth year using John Deere round module pickers. We had three last year and we’ll be running four this year. There is night vs. day difference in these pickers and the conventional pickers and support equipment we were using previously. It took a village to support those machines.

“In addition to the greater efficiency of the new pickers, it’s much easier to move from field to field because we don’t need all the boll buggies, tractors, etc. Previously, we were using 16-20 employees for cotton harvest; now we need only five. That’s a tremendous productivity advantage.”

Variable rate defoliation, one application

Although there was skepticism when the Sewards began working on variable rate defoliation of cotton, the practice has proven successful, Darrington says.

“We now use variable rate technology for all our defoliation, based on aerial images of the fields taken during the season. We make one defoliant application, using Finish and Dropp — and that’s it. That compares to other farmers who make two or three defoliant applications.

THE SEWARDS have fine-tuned one-application variable rate cotton defoliation based on aerial imagery.

“We get consistent results, and we’ll be picking a week earlier than those who defoliate conventionally. Variable rate defoliation is equally effective whether we do it ground rig or airplane — you can’t tell the difference.”

All their soil data are stored in OptiGro. “We can tailor fertilizer and nutrients for each crop on each field,” Darrington says, “All of our field data can be used for variable rate application of fertilizer, either by ground or aerially, with comparable results. The accuracy range is within 5 percent for either method.”

About 70 percent their farmland is irrigated; there are 26 center pivots, and the rest is furrow. “We have both electric and diesel irrigation wells,” Darrington says, “and we can monitor them remotely and collect data on water usage, which we report to the water management district. We can monitor engine performance and see status of the pivots. We can turn some systems on or off remotely.”

ON-FARM DRYING enables the Sewards to efficiently handle harvested grain from their five combines. Darrington Seward stands in front of the dryer that can process 100,000 bushels of corn per day.

The Seward operation was “wall-to-wall cotton in the early years of the farm,” Darrington says. “Then we began adding some soybeans, and we started growing corn in the early 2000s. We’ve also grown rice in the past, but got out four years ago when we were having variety issues. I don’t know if we’d grow rice again — we never had more than 1,000 to 1,500 acres, and there’s a lot of labor involved for a relatively small acreage. It’s a good rotation crop for soybeans, but we’d have to look hard at getting into it again.

“We rotate cotton and corn acres every year, and on our soil types this really works well. We have some resistant pigweeds, but not as bad as in the upper Delta. We are very aggressive in our rotation of chemistries to ward off resistance. We applied Cotoran on 100 percent of our cotton acres, and we use residuals everywhere we can. We carry out an aggressive burndown program, using Roundup mixed with other chemistries, starting in December for the following year’s crop. Next year, we plan to grow some dicamba cotton.”

The Seward farming operation was started in the 1930s, with 7,000 acres or so acquired during the Great Depression, says Darrington, the fourth generation on the farm. He earned two degrees at Ole Miss, one in history, another in English. “I always knew I was coming back to the farm,” he laughs, “and I wanted to take subjects in which I had an interest.”

The early-day farm had commissaries at two locations, Louise and Midnight. “As opportunities came along, more land was acquired, and today we farm 22,000 acres, about 70 percent of which is owned,” he says. “Much of our growth has occurred over the past 20 years, and if opportunities present themselves for more land, we would consider further expansion.”

About the Author(s)

You May Also Like