December 30, 2020

What humans see is a pretty wide range of visible light, but anyone who has looked at a normalized difference vegetation index knows that infrared and other forms of light can paint a deeper picture of crop health. Startup HinaLea Imaging is working with a more precise measurement and broader light spectrum, and will soon make that information available for enhanced precision ag management.

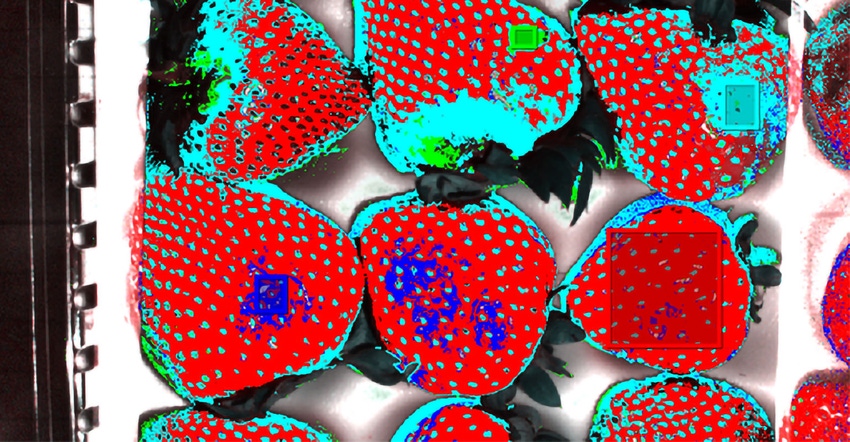

Hyperspectral imaging provides detailed spectral and spatial information, and when that information is teamed with artificial intelligence systems, it can be used in new ways. In fruit processing, the systems can be used to judge in-field condition of fruits or vegetables. But that same technology can be used to measure soil health or other characteristics that can then be managed to boost yield.

“Hyperspectral imaging is a powerful sensing solution that combines spectroscopy with digital imaging, and in the past, that has been used in defense, and it was not cheap technology,” explains Barry McDonogh, general manager, HinaLea Imaging. “One of the things we’re looking into is to get the unit cost way down.”

McDonogh says hyperspectral imagers often started at $70,000 and ran into the hundreds of thousands. Often these are large, stationary machines. HinaLea is aiming to get that price below $15,000 when purchased in bulk. The price could be lower.

That sounds high for an imaging tool, but he says the information provided can be used in many ways — if you can read it. “That’s the other change we’re making in the technology. It used to take a Ph.D. to operate one of these imaging machines because they kick off a huge amount of information,” he says. “We’re reducing that challenge by using artificial intelligence.”

The key is a series of machine-learning tools that can be customized to process the information and highlight the data you need to know about. For example, if a soil sample read by the imager shows a nutrient challenge, the system would highlight the key areas where action is needed.

In processing, these tools could measure brix (sugar content) of fruits, or identify a particular disease or pathogen in a crop.

“We’re doing the initial work with customers to understand their problems and develop custom solutions that are intuitive and easy to use,” McDonogh says.

Processors and more

This technology will be deployed in a range of areas across agriculture. Beyond measuring brix, big food companies will be using this tech to measure crop health, moisture content, levels of bruising, and defects or foreign object detection. The system can also be used to identify a range of toxins such as aflatoxin in peanuts. “The technology has the potential to add enormous value in food processing,” McDonogh says.

HinaLea’s effort to reduce the price of these tools is what will set the company apart. It’s also combining the hardware with custom machine-learning tools to develop the product based on what the customer needs. “Our technology allows us to see the world differently, and we use this to solve customer problems,” he says.

The system also has value for greenhouses and indoor farming operations for measuring changes in the crop. “It just depends on what you’re looking for,” he says. “This is a very portable unit that can be placed in different areas, depending on the application.”

The system can be dynamically adjusted to capture only the spectral information of interest. In this way, a user can perform real-time hyperspectral imaging and classification. Take fine-tuning imagery. If you can measure 300 bands but only 10 or 20 are needed to do the job, that’s what the system can be designed to do, which can cut costs.

Pathology detection is a hot area. Identifying a disease or the presence of a disease can take time and be costly. With this system, the readings can be nearly in real time, saving time and cutting processing costs.

And if this technology were deployed for measuring soil attributes, done in real time, soil testing could be more frequent. More accurate readings of nutrient availability could be a benefit to farmers. Imagine a hyperspectral imager on an all-terrain vehicle or a drone, taking readings and providing in-depth detail on soil conditions, nutrient levels or moisture in near real time.

Those are just some of the many ways this tool could be used. HinaLea is working to make it happen, and McDonogh acknowledges that the process will take time. “We don’t know the problems or measurements that need to be taken,” he says. “We don’t want to sell just hardware; we want to sell a solution.”

While processors will probably be the first to benefit from this tool, smaller, less-expensive imaging tools could bring this technology to the farm in the near future. You can learn more at hinaleaimaging.com.

About the Author(s)

You May Also Like