October 26, 2020

The 2020 corn harvest in Iowa is likely to include increased amounts of damaged grain from the drought and derecho, along with excessively dry corn.

While cleaning grain as it enters the bin is an option to remove excessive fines and broken kernels, it’s not an option many farmers can turn to without the proper equipment.

As grain bins are filled, fines, and broken or damaged kernels tend to accumulate near the center of the grain pile, while whole kernels and higher-quality kernels tend to slide to the outer edges of the pile. This leads to a concentration of low-quality and damaged grain in the center core of the bin. Also, with the greater depth of grain under the center of the peaked fill, this central core receives less airflow and is at higher risk for spoiling.

“You can reduce this risk by coring the bin as soon as it is filled,” says Kristina TeBockhorst, an Iowa State University Extension ag engineering specialist. She and colleague Shawn Shouse, also an ISU Extension ag engineer, offer the following recommendations.

Reasons to core

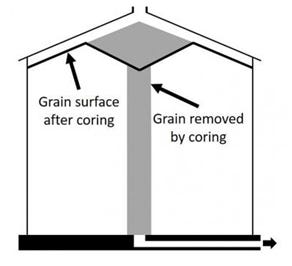

Coring the bin removes the narrow cylindrical core of grain extending from the grain surface at the top of the bin down to the unloading sump. The center peak will be the first grain drawn down through this core to the unloading auger. Unload until half of the grain peak is removed and the grain surface makes a “W” shape. This serves two purposes.

First, the center core of grain with the highest concentration of fines and damaged kernels is removed.

Second, the grain depth at the center of the bin is now roughly equal to the grain depth at the sidewall, making the overall grain depth more uniform. Both will result in increased aeration uniformity and reduced risk of grain spoiling during storage.

How much to remove

The number of bushels to remove to reach half of the peak height is a function of bin diameter, TeBockhorst explains. The bushels to remove when coring is equal to the bin diameter (in feet) cubed, divided by 90. Thus, bushels equal diameter times diameter times diameter, divided by 90. For a bin with sidewall height roughly equal to its diameter, coring bushels equals about 1.5% of bin capacity. If sidewall height is only three-quarters of bin diameter, coring would remove about 2%. And if sidewall height is 1.5 times diameter, coring would remove about 1%.

“Core each of your bins this fall and contact your ISU Extension field ag engineer if you have questions,” she adds. Cored grain can possibly be used for livestock feed or sold to an elevator.

Avoiding potential problems with molds and mycotoxins is another reason to core your bins, Shouse says. Coring bins is needed to remove the light grain, fines and damaged grain particles that are potentially prone to become moldy as they accumulate in the center of a bin. Molds can form toxins, which are usually much higher in the fines in the core as well.

For information on drying, handling and managing stored grain, visit ISU Extension.

Source: ISU, which is solely responsible for the information provided and is wholly owned by the source. Informa Business Media and all its subsidiaries are not responsible for any of the content contained in this information asset.

You May Also Like