March 26, 2020

“See how the cutter bar is attached to the extra-wide yoke with large, hardened-steel pins, making an extremely strong connection. Examine the cutter bar, guards, sickle bar and new automatic pitman. Notice how the extra-long, wide knife head runs on steel wearing plates, front and rear.” That’s how John Deere describes the “cutting-edge” technology of the No. 4 sickle bar mower in a huge, foldout, mailer in the mid-1930s.

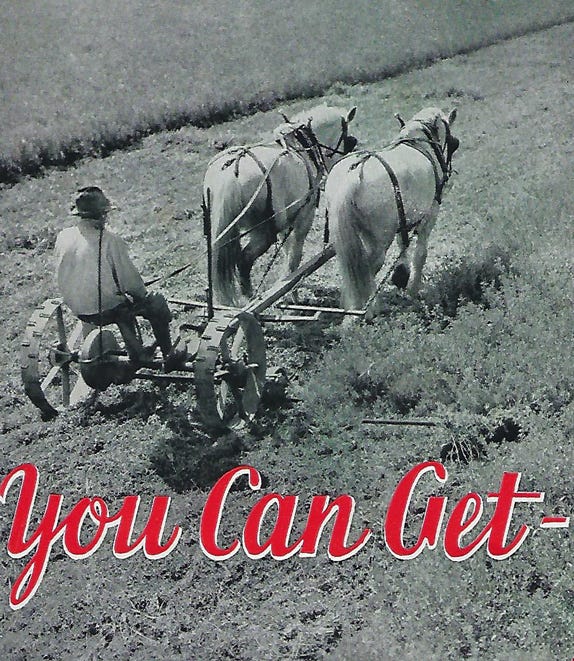

Most of the brochure features the horse-drawn, steel-wheeled No. 4 mower, available in 4-, 4.5-, 5-, 6- and 7-foot mowing widths. You could get it with a quick-turn tongue-truck to simplify turning.

A 7-foot-wide mower was a large mower in the ’30s. John Deere still offered 7-foot cutter bars on tractor-mounted mowers in the ’60s.

JOHN DEERE NO. 4 MOWER: This horse-drawn mower dates most likely to the early 1930s. The same brochure also features pictures of very early John Deere tractors pulling the same mower.

Hay rakes and more

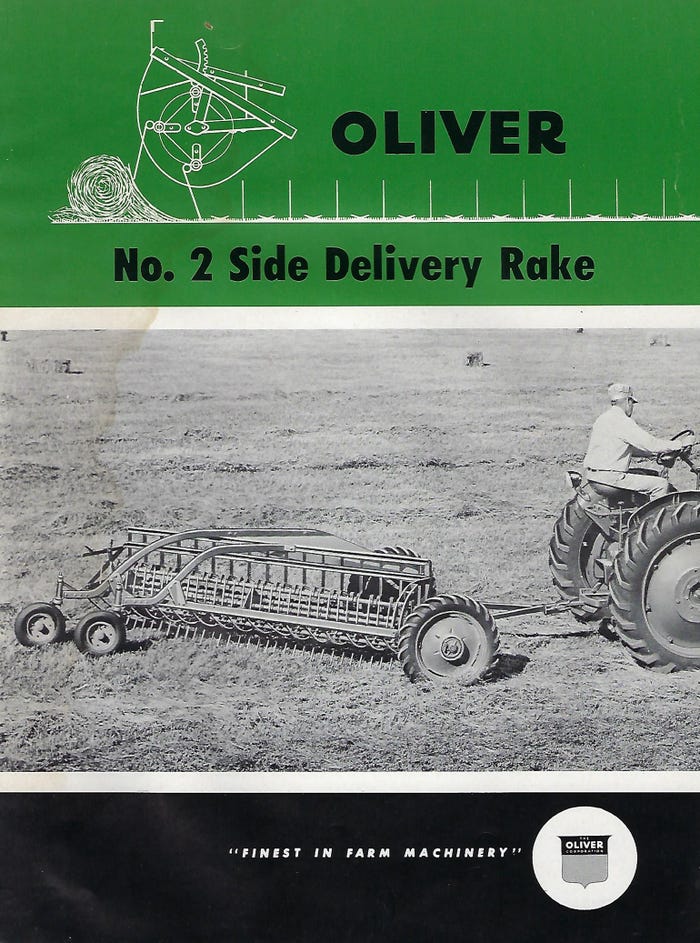

Oliver was one of many companies offering side-delivery hay rakes by the mid-1900s. The No. 2 side-delivery rake featured a pair of rubber tires up front and smaller rubber tires behind. The brochure for the No. 2 rake claims, “Strong and compact — light in draft, leaves your fields clean.”

The brochure fails to mention that if your field was uneven, some rake teeth would likely dig into the dirt and break off. There are likely still a few rake teeth from side delivery rakes of various brands of that era buried in former hayfields.

SIDE-DELIVERY HAY RAKE: The same brochure featuring this hay rake still promotes an earlier steel-wheeled, horse-drawn model.

John Deere, New Holland and many other companies introduced small-square balers. At first, many operated off gasoline engines. Allis-Chalmers produced the Roto-Baler, which made small round bales, in the 1950s.

Latest innovation

Perhaps Allis-Chalmers was ahead of its time. An Iowa farmer, Gary Vermeer, built a baler in the ’70s that made big round bales and reduced manpower requirements. Big round balers took off. Today, they’re joined by big square balers.

GAS-POWERED BALER: Gasoline engines on hay balers were common in the mid-1900s before the shift to predominantly PTO-driven implements.

Recently, Hesston by Massey Ferguson took haymaking deep into the 21st century. In February, the Agco brand unveiled Bale Link, a bale management system. Each bale can be identified and tracked via an attached RFID chip. Using an app available for both Android and Apple smartphones, you can enter production information and track the bale back to where it was produced.

The RFID chip is woven into a strand of twine on each large square bale. BaleCreate software captures the serial number of the RFID chip, plus bale weight and length, number of flakes, moisture, date and time baled. Coupled with GPS coordinates, the information is transferred to Agco servers using the Agco Connectivity Module.

Using a hand-held scanner, you can retrieve information. The system will allow hay growers to prepare loads of the same type of hay, and track and document each bale. It will be field-tested this summer, with full commercial release expected in 2022. Learn more at masseyferguson.us.

Comments? Email [email protected].

You May Also Like