October 1, 2018

Sponsored Content

Higher yields. That’s the number one goal with residue management in corn. Generally, the last thing a farmer wants to do is leave something valuable behind in the field after harvesting it. But, what you may deem “not valuable” may offer more benefits than you think. Under certain circumstances, corn residue can provide additional nutrients for next year’s crop, in turn rewarding you with additional yields. However, these benefits require proper management – or residue can actually be problematic.

For many years, Beck’s Practical Farm Research (PFR)® team has tested multiple practices and products in order to discover ways farmers can use residue to their advantage. In order for microorganisms to decompose residue, they use nitrogen (N), hydrogen and oxygen to break down carbon bonds. Once finished, they release the previously tied-up N back into the soil. This process generally begins in the fall, pauses once microorganisms begin to die off when the soil freezes in winter, and resumes in the spring when soils warm up again. In a corn-after-corn rotation, this can be especially problematic if your residue-bound N is still immobilized in the soil early in the growing season when your corn needs it most. It takes about 30 lb. of N to break down every ton of dry corn matter residue left in your field after harvest. Each ton of dry matter contains about half of the necessary N to do this, so the remainder of the N must come from the soil, or another source.

There are a variety of factors that can affect residue breakdown and the carbon penalty in your fields. If you have warm, moist conditions for an extended period of time after harvest, your soils will begin the process of breaking down the residue sooner and continue to live longer. If you work your residue in the spring, the microorganisms that break residue down will build up as your soils warm up. By tilling earlier in the fall, you can begin to build up microorganism populations sooner and potentially reduce the N penalty in the spring. As the organisms that break down your residue become active in the spring, you want to ensure you have enough available N to feed them. Eight years of Beck’s PFR data indicates that an additional 30 lb./A. is necessary in-season.

While these management practices impact decomposition, Beck’s PFR has analyzed the effectiveness of equipment technologies and specialized products designed to address carbon penalty as well. By increasing the surface area of the residue, and/or offering the microorganisms additional nutrient supplements, the PFR team has found you can help speed up the breakdown of residue – making more N available in the soil sooner for your plants.

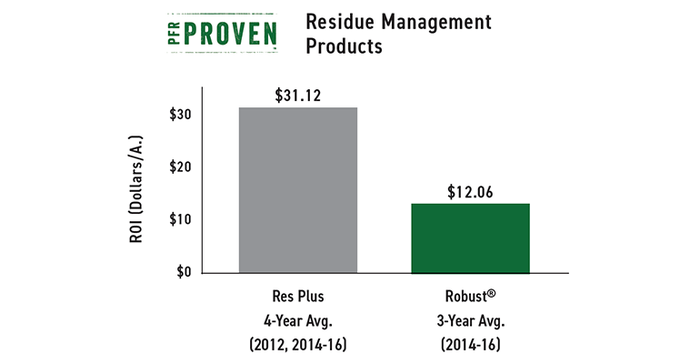

For four years, Beck’s PFR has tested products that claim to accelerate the decomposition of residue in the fall. These products contain either a bio-stimulant that accelerates residue breakdown or nutritional and activating agents that improve microbe health and residue breakdown. The timing of these products’ application and fall weather can play huge roles on breakdown, as well. Two products, Res Plus and Robust®, became PFR Proven™ products after consistent yield increases and average positive ROIs over multiple years.

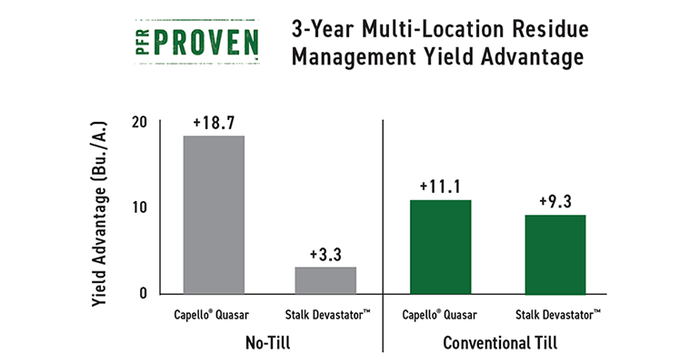

There are also equipment technologies that address carbon penalty by sizing and/or scoring the residue in order to create smaller pieces and/or more entry points for the microbes to enter the stalk and break it down. Reducing residue size increases the surface area of the residue, which allows soil microbes to be more efficient in residue decomposition. The PFR team has tested different heads and snapping rolls on combines to see what they bring to the table. Two pieces that have been named PFR Proven™ by Beck’s PFR are the Capello® Quasar Corn Head and the Yetter Stalk Devastator™.

As you plan your cropping systems, don’t forget to keep in mind some hybrids produce much more residue due to their plant stature and structure. It may be a good idea to consider how you manage residue year-round, especially in a corn-after corn rotation.

For more information about these studies, or to see regional results, click the links below.

Beck’s PFR is the largest source of unbiased, cutting-edge agronomic information in the industry. More than 500 studies were conducted in 2017, comparing over 150 products across multiple locations to learn how different management practices and new technologies perform in field environments. In evaluating agronomic practices and input products, not comparing seed products, Beck’s PFR aims to help farmers maximize their input dollars and increase their bottom line. To view more PFR studies click here.

Practical Farm Research (PFR)® and PFR Proven™ are trademarks of Beck’s Superior Hybrids, Inc. PFR Proven™ was developed in 2016 to identify the products and practices that are likely to be most profitable. If a product has been tested in PFR and found to provide yield gains and averages a positive ROI over a minimum of three years, then that product will earn the status of PFR Proven and should be something to consider trying on your farm. If a practices has been tested in PFR and found to be the most profitable, then it will also receive the status of PFR Proven. Please consult with your local Beck’s representative or trusted advisor for best management practices in your area.

Capello® is a registered trademark of Capello USA. Stalk Devastator™ is a trademark of Yetter Manufacturing Company, Inc. Robust® is a registered trademark of Rosen’s, Inc.

About the Author(s)

You May Also Like