Better planes, better chemicals, and better field-mapping options make an aerial applicator’s job easier today than was the case a tad more than 40 years ago when Pat Ryan began a career as an ag pilot.

But weather, the stress of making accurate and timely applications, and the commitment to provide top service to customers remain as pressure points for today’s flyers.

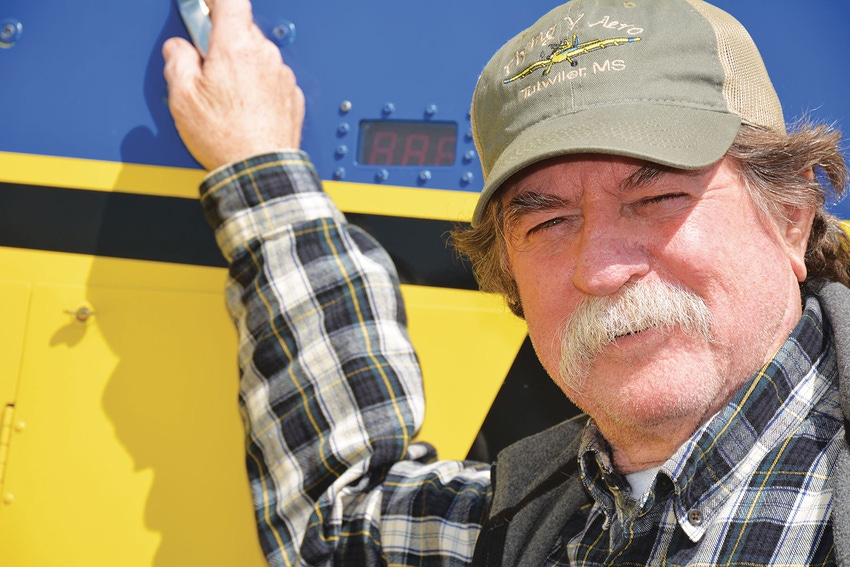

Ryan, president of Flying Y Aero, Inc., at Tutwiler, Miss., started his aerial applicator career in 1975. He had been in warrant officer training on helicopters until medical issues prevented him from finishing the course. He completed two years of military service, then got his private pilot license, including for fixed-wing aircraft.

“I started working with my ex-father-in-law,” he says. “I was mostly flying helicopters, but wanted to fly planes, too.” His father-in-law nixed that notion for a while until he needed Ryan to pick up a new plane and fly it home. “He needed me to help get caught up one particularly busy year.”

Back in the early days, Ryan says, flagging fields was one of the most difficult things about applying chemicals or fertilizer to cropland. “We had to get up early to get started, and farmers had to get up even earlier to get their people set up to do the flagging. They did it all by hand.”

GPS takes care of that chore now, and has been “one of the best changes” in the business, he says.

BETTER PLANES, TECHNOLOGY

Planes are better today, more powerful, and have better technology, Ryan says — plus one big improvement over the old models: “They are air-conditioned. Just 10 years ago, we had some air-conditioned planes, but the AC was operated by wind-driven pumps, so it didn’t work when we were on the ground.

“We can carry more load now than we could then,” he says. “Those old planes couldn’t carry anything close to 500 gallons of liquid. We used to run Air Tractor 301s, which could only hold 300 gallons, but the wind had to be just right and the field had to be convenient for us to even try to haul a full load. Now, we have aircraft that can routinely carry 500 gallons to 600 gallons.”

Today’s turbo planes can fly faster and carry more material than the older radial engine aircraft could handle. “Twenty years ago, we flew 110 mph to 120 mph, Ryan says. “Now, we fly 150 mph to 160 mph, with a lot of instruments and a lot of refinements.”

He says regulations have changed, too. “Some of the things we used to do, the EPA won’t allow now.” That includes burning tires to create smoke to mark wind direction. He recalls a conversation with an ag pilot from California who talked about his “smoke generating machine — a 55-gallon drum with a tire burning inside.”

JOB NOW MORE TECHNICAL

The chemicals ag pilots carry today are much improved over those available when he started, Ryan says, but the complex mixtures they apply to crops “can be a nightmare. We apply mixtures to specific fields and crops that could be detrimental to an adjacent crop of a different variety. The job today is more technical.”

He recalls applying pesticides that required precision — 2,4,5-T and others. “It was like going off with a rattlesnake in your pocket: You were just waiting to get bit.”

Ryan brought in two young pilots, Elliot Hendrix, 26, and Brian Roach, 36. Both graduated from Delta State University at Cleveland, Miss., Hendrix with a bachelor in business management, and Roach with a degree in commercial aviation. Roach has worked at Flying Y Aero as a pilot for the last 12 years and Hendrix for the past two years.

They agree that technology — including the ability to mark fields with precision based on GPS technology — makes the job a bit less onerous than in the early days. Chemistries, too, have improved.

“The advancements in mapping technology are a big help,” Roach says.

But some of the issues that have bedeviled ag pilots since they started applying chemicals by air continue to create stress. Time constraints, especially during the early part of the growing season when demand for fertilizer applications is at its peak, mean a lot of long days.

PLANNING IS CRUCIAL

“Farmers want to apply fertilizer prior to a forecasted rain,” Roach says. That often results in last-minute requests to make an application within a day’s time. “We get calls like that almost every day during the season,” Ryan says. “That is where planning is crucial on the farmers behalf.

Roach says, “It’s not just the challenge of working another farm into the next day’s schedule, but they also have to consider that the aerial applicator has to get the product. We’re dependent on the fertilizer warehouse.” For some locations, he says, they also have to arrange for other landing strip availability. “Communication is essential.”

It’s critical, Hendrix says, that farmers and consultants be certain of the rate and brand of chemical prior to scheduling application. “Our prep work and plans are made prior to getting into the aircraft. We organize our loads around critical areas such as houses, towns, and other crops. So, if a farmer changes his mind about something such as a rate, or decides to add another chemical while the application is in process, it could cause the application to be delayed, which could leave the job incomplete until conditions are right again.”

UNDER IMMENSE PRESSURE

“We understand that a farmer is under pressure to get products applied,” Ryan says, “but we also have a schedule to keep.”

Roach says, “June is our busiest and most hectic month. We are under immense pressure to apply fertilizer, insecticide, and herbicide on time, during the middle of the growing season.”

Custom applications add another level of complexity. “We often have a different cocktail for each field,” Roach says. “That’s where technology and productivity collide.”

They say the most mentally taxing part of the job is to know who has which crop planted where. “With the vast array of crop varieties these days, you can never be too careful,” says Roach. “When I started in this business, everyone usually had rice, beans, corn, or cotton, and for the most part, you knew which chemicals went on each crop. But now, it seems like each variety has its own recipe.

“For example, if a grower brings in maps for a bean field that needs a herbicide application, not only must you know which other crops are around that field, but also the variety of crops. Even if the field lies in a sea of other bean fields, you still have to know which variety is planted where, because some varieties might not tolerate that particular herbicide (example, Roundup can’t be applied on conventional beans). That concept applies for rice application as well (Clearpath can’t be applied on conventional rice).”

MORE FALL BURNDOWNS

“The dicamba issue,” Roach says, “does not pertain to us. In a way, I’m glad that dicamba doesn’t have an aerial label. But I believe it is a very useful tool for growers.”

The pilots say farmers who apply fall burndown herbicides also take a bit of pressure off the spring workload. “I’d like to see more farmers make a fall burndown application — not too many, but a few more.”

They all agree that the most critical issue for aerial applicators is the one that has always been top priority, customer service, and that better communication will benefit both farmer and ag pilot.

“Communication is key,” Hendrix says, and Roach agrees. “That’s the biggest thing: We want to do the best job we can for them.”

“Keep us in the loop,” says Hendrix, and that includes alerting pilots to changes in field layout, and new structures, such as cell towers or irrigation systems added since the last spray season.

Farmers also should be aware of the pilot’s limitations in doing safe, accurate work during marginal conditions. Wind is a constant factor. “Sometimes, we just have to tell a farmer no, but we try to avoid those situations,” says Roach.

“We’ve flown in winds that were gusting up to 40 mph — at the grower’s request,” Hendrix says. “We do our best to give the growers what they want, but sometimes conditions are flat-out unsafe.”

“It’s always the pilot’s call, before he gets in the plane,” Ryan says. Roach agrees: “We can’t worry about what someone else is doing. We have to concentrate on what we’re doing and be safe.”

About the Author(s)

You May Also Like