September 2, 2016

Ben Singleton

CFO, Anson Family Farms

Monroe City, IN

Tell us a bit about yourself and your farm.

I grew up on a small cattle operation in Indiana, and all throughout school my goal was to get as far away from farming as possible. I got an accounting and finance degree and worked as a public accountant.

I married my high school sweetheart. Her family owned a pretty large operation and there was a big need for someone with my background. So I became the CFO, but I am also involved in the operational side. I manage our soybean planting and one of the harvest crews.

Our family farms around 20,000 acres in eight counties in Indiana and Illinois. We typically are doing a 50-50 corn-soybean rotation, and we’re all no-till, using cover crops on most of our acres. We’ve grown a lot and very quickly.

Across your farm operation, what data does your equipment collect? How often do you use it? What kind of decisions do you make with it today??

We run all John Deere equipment that captures everything that happens - what was planted, what was sprayed, harvested, etc. The data is on JD’s cloud, which allows us to access it from anywhere. We farm many different types of ground – some good, some poor, river bottoms, etc. – so crop insurance is a very big deal for us. The primary use of our equipment’s data is for crop insurance reporting.

How do you optimize your equipment during potentially hectic times like planting or harvest?

I’m involved in the soybean planting operation. My brother-in-law runs corn. We don’t use equipment data to dictate who goes where. Our strategy is to have high-level management directly involved in the operation during those times.

Does your equipment "talk" to each other?

No - but the option exists. It would be beneficial but at the moment it’s a bit too expensive for us. If we have two guys on the same field, it could be nice to see each other's’ coverage maps. It would also be nice in the fall to see the combines’ monitors as we run grain carts.

How do you integrate machine data with your guys’ field work?

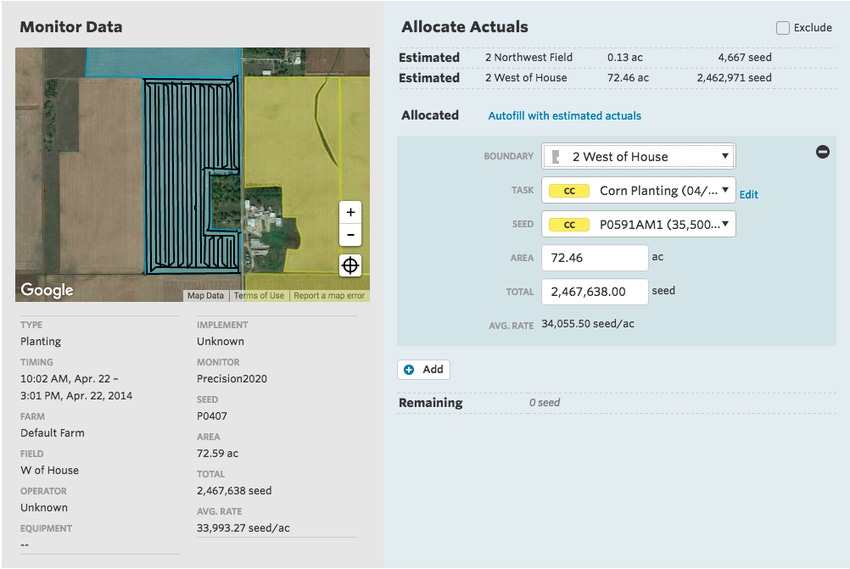

We use Granular’s mobile app to get their work orders and know where they need to go and what they need to do. They don’t always enter the actuals correctly - for example, they’ll enter pounds instead of tons or enter the total seed population instead of the rate. It’s great to be able to check with machine data and flag mistakes immediately once they click “Complete”.

What kind of decisions would you want to make with machine data in the future?

The reality is that we’re not able to truly make decisions yet, we use it for reporting. We’ve been capturing and using the data this way for years. Up until recently we didn’t have the technology to use it to manage the business. For a long time it lived in a desktop machine that was so full we couldn’t even turn it on one day.

Then we moved to a server that was better but still slow. It was also really cumbersome to get all the data in one place. We have three planters running in the springtime. Back then it was next to impossible to gather all the data and see it in real-time. By the time we got everything together and looked at it, if something was wrong, it was too late.

What gets exported out of the monitors today is only part of what that machine is capturing. It would be nice to get information on spacing, speed, etc., so that someone can evaluate, for example, if they should be driving at 4, 6, or 7 mph. Should we get another planter and drive slowly because it results in better yields and higher profitability?

I also want to be able to use data like this to compare the different types of ground that we farm. Are we better off running more equipment? Farming less but more profitable land? We’re probably not doing everything right. We’re getting there with Granular. Our goal is to get to activity-based costing and be able to filter this data in meaningful ways. We're getting there - and we’ll be fully there soon.

There’s nothing unique about what we want to try to do with this information. But I’m hoping that with the equipment we have and my accounting background, we'll be able to pull it off sooner than others.

About the Author(s)

You May Also Like