December 11, 2017

Farmers like ag innovations that focus on making their jobs easier, as GSI proved during the fall farm shows. The company rolled out the FlexWave grain bin cleanout system to plenty of interest from farmers. And even at Agritechnica in Germany, farmers were very interested in the system.

The innovation uses liners at the base of a bin that inflate sequentially to remove the last bit of grain by “rolling” it into a central unload auger. The system promises greater than a 99% cleanout, and no one has to get into the bin. That job, often taken on in late summer, can be hot, sweaty and dusty work.

However, farmers seeing the liner inflation system in place had one question: “Can you aerate the grain with that installed?”

The answer from preliminary tests this fall is “yes.” That grain can be aerated, which offers a proof of concept answer for farmers concerned about moving air through stored product. While more testing is planned, according to Jonathan Waits, GSL product manager-storage and accessories, “We did prove we can aerate the grain.”

The exact approach to aeration is still under review, but Waits says the company will have systems for the market - on a limited basis - in 2018.

The initial test involved an eight-ring, 48-foot-diameter grain bin filled to a 30-foot depth with corn from a portable dryer. The bin had 13 temperature cable sensors inserted at different depths to measure how effective the fans were in distributing air through the grain.

The first aeration approach distributes air from the central trough. It’s by no means a final design, Waits says. “Right now that’s the easiest method, but there are a few other things that could drive us to different decisions for the aeration approach,” he says.

The aim is to get air into the grain, and you have to move the right amount of air to get that done. “There are a few factors driving our decisions about the final approach,” Waits says.

This is a preliminary result — but the grain was coming off the dryer into a bin, and the outside temperature was warmer than average given the kind of fall farmers faced in Illinois this year. “It was warm,” Waits says.

Next steps and coming to market

GSI engineers will turn their attention to working with different-sized bins with different capacities. That way, the company can develop the right system to maximize the FlexWave and provide proper ventilation for the grain.

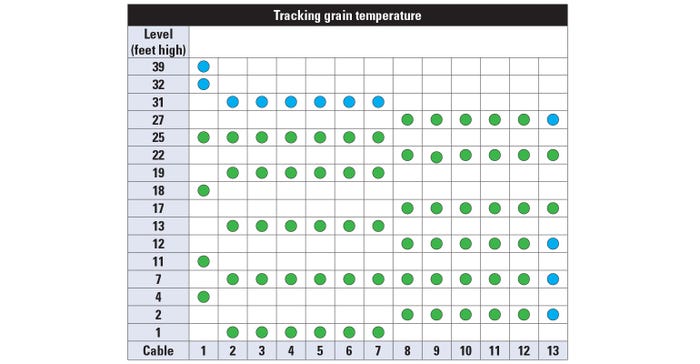

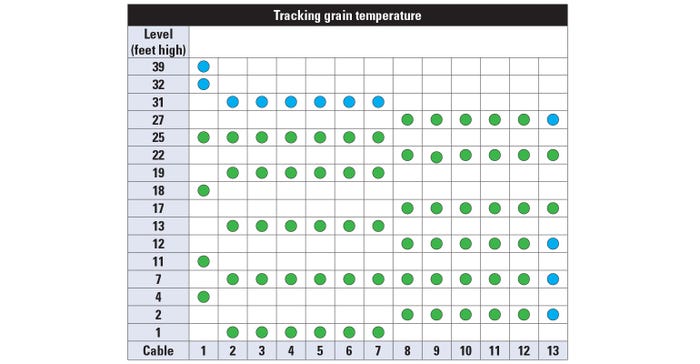

This image of sensor information shows that throughout the bin, grain stayed at the proper temperature during tests this fall. Note that the sensor location is actually in a circle around the bin. The blue circles indicate cooler areas, most likely because the sensor was above the grain or near the outside wall. Neither impacts grain quality.

The graphic above shows the temperature sensor data in a row — in fact, No. 1 was in the center of the bin, with the other 12 in a spiral through the bin. A look at the data shows a lot of green, indicating temperatures within the target range, but there’s blue, too. Those blue readings show when the temperature is lower than optimum. “There are two reasons for the blue readings,” Waits says. “First is that the sensor could have been above the grain column, so it would have been cooler. Second, the sensor could have been nearer to the bin edge, which would have impacted the readings.”

The lower-than-optimum readings won’t affect grain quality, Waits observes.

As for coming to market, the first aeration test is not exactly the likely application for 2018. “Our first product, in limited production, will be more for hopper bins and smaller-diameter bins, where the grain is moving in and out more frequently,” Waits says. “The test we conducted was for long-term storage, and we won’t have that product until the 2019 harvest.”

The appeal of this system is ending the need to climb into a bin for final cleanout by automating the process. Answering the aeration question, even with this preliminary result, is good news for the future of this product. You can learn more by visiting grainsystems.com/flexwave.

About the Author(s)

You May Also Like