August 13, 2020

The first robotic cutting mechanism, or “end effector,” for a fully automated, computerized pruning system for modern apple orchards has been designed by a Penn State research team, an early step in the creation of a technology aimed at easing challenges facing tree fruit growers.

Pruning apple trees comprises about 20% of total preharvest production costs, and the tree fruit industry is struggling with increasing labor costs and a limited labor pool. Automated or mechanical pruning could largely solve those problems, according to researcher Long He, assistant professor of agricultural and biological engineering.

In the U.S. the tree fruit industry contributes one-fourth, or $18 billion, of all specialty crop production, and apples are one of the most valuable. Pruning is a necessary cultivation technique that affects fruit quality, quantity and the efficacy of pest control, and it is still largely dependent on manual labor. Between 30 and 50 working hours of skilled labor is required per acre for manual pruning of apple trees.

“Robotics and automation technologies are now extensively used in agriculture, while production operations of tree fruit crops still depend on manual labor,” He says. “One big reason is that robotic pruning involves several challenges due to the unstructured working environment.”

Building a prototype

In the study conducted at Penn State’s Fruit Research and Extension Center, researchers first measured branch-cutting force with a sensor attached to manual pruners to provide information for the end effector design. An end effector is a device or tool that's connected to the end of a robot arm where the hand would be.

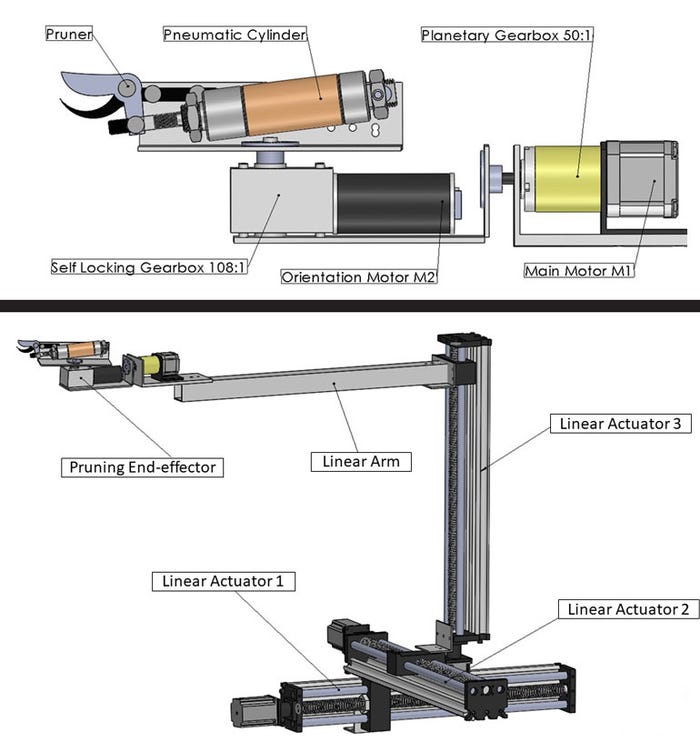

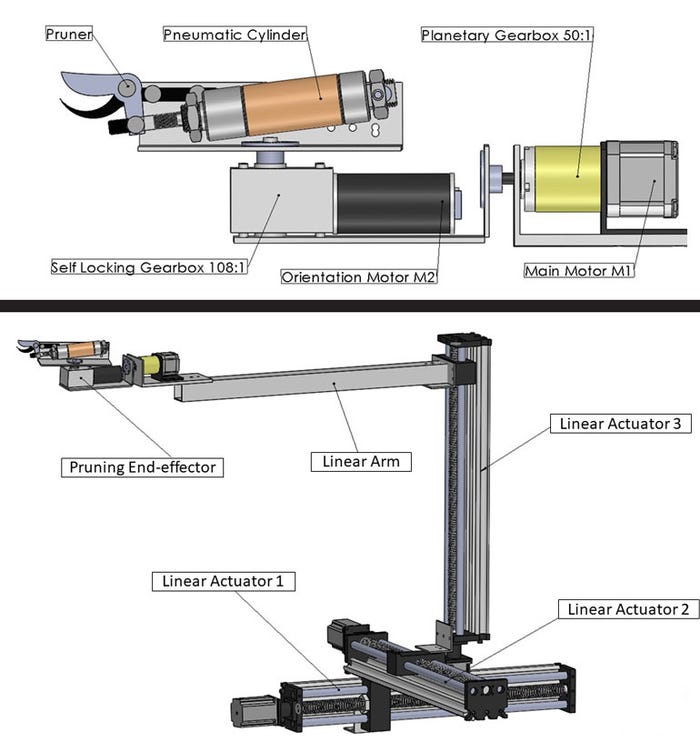

The pruning end effector was developed using two rotary motors, a pneumatic cylinder and a pair of shear-blade pruning cutters. A three-directional linear manipulator was built to house the end effector and move it to the targeted pruning locations.

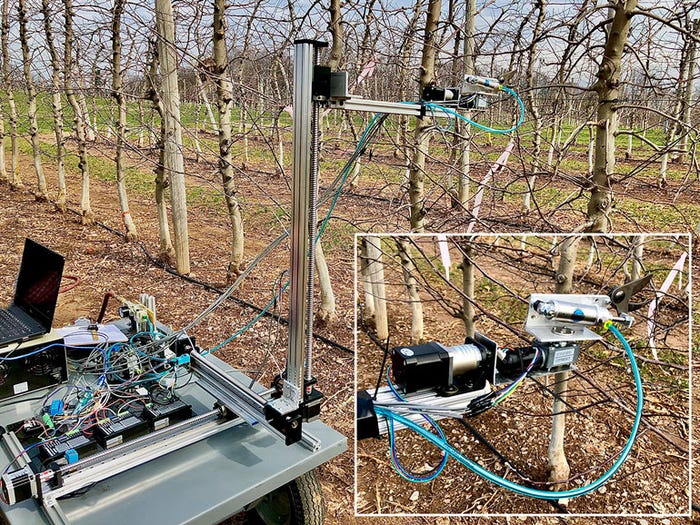

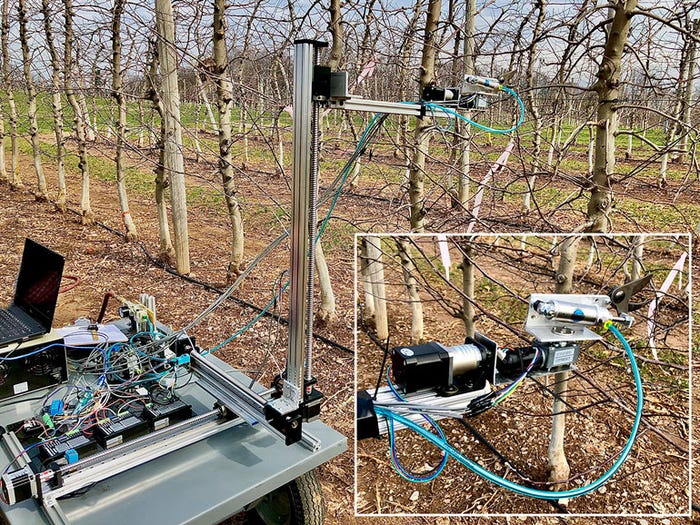

PROTOTYPE PRUNER: The end effector prototype was tested at Penn State's Fruit Research and Extension Center in Biglerville.

PROTOTYPE PRUNER: The end effector prototype was tested at Penn State's Fruit Research and Extension Center in Biglerville. There were major challenges to creating a mechanical system that would succeed in a complex agricultural environment. The robotic cutting unit had to be able to operate in tight spaces and reach targeted branches for pruning while avoiding the tangle of other branches.

PROTOTYPE PRUNER: The end effector prototype was tested at Penn State's Fruit Research and Extension Center in Biglerville.

To guide the maneuvering of the end effector and the manipulator control, they developed an embedded microcontroller system with a user interface using an interactive mathematical program that allows calculations to be visualized. A mathematical model was developed for simulation of workspace utilization and reachable points for the end effector.

The researchers conducted field tests to assess performance of the prototype. In results recently reported in “Transactions of the ASABE,” they reported that the end effector successfully cut branches up to a half-inch in diameter. The field results also showed that the proposed pruning end effector could cut the branches at a wide range of possible orientations in a given space.

Solving challenges

There were two major challenges to creating a mechanical system that would succeed in a complex agricultural environment, according to lead researcher and Ph.D. student Azlan Zahid.

First, the robotic arm and cutting unit had to be able to operate in tight spaces because apple trees have many branches and their orientation is random. The cutting mechanism must reach targeted branches for pruning while avoiding the tangle of other branches.

In an innovative move, the researchers incorporated the integrated design of a pruning robot with two rotational joints and three linear or prismatic joints to accomplish this mechanical dexterity. The aim was to reduce the spatial requirements for maneuvering into position and align the cutter perpendicular to the branches.

The second challenge was “trajectory planning.”

“We had to develop a compact arm and cutting mechanism that can orient itself at almost all possible angles in the workspace,” Zahid says. “And we have to reach to any branch, despite the very high chance of having a collision with other branches.”

The robotic end effector is a core component in an entirely automated pruning system for fruit trees, envisioned by He.

PROTOTYPE DESIGN: This model of the end effector shows how it achieves a high degree of mechanical dexterity. It is envisioned by researchers as a core component in an entirely automated pruning system for fruit trees.

PROTOTYPE DESIGN: This model of the end effector shows how it achieves a high degree of mechanical dexterity. It is envisioned by researchers as a core component in an entirely automated pruning system for fruit trees.

“We would like to collaborate with some other institution such as Washington State University on the machine-vision component, but for now the plan is to develop our own system here at Penn State, maybe starting next year on the machine-vision component,” he says. “I would like to see if we could develop it on our own. But opportunities to collaborate may depend on whether we can get funding from the federal government or stakeholder groups.”

This research was supported by the USDA’s National Institute of Food and Agriculture, Northeast Sustainable Agriculture Research and Education and the Penn State College of Agricultural Sciences’ Stoy G. and Della E. Sunday program.

Source: Penn State University, which is solely responsible for the information provided and is wholly owned by the source. Informa Business Media and all its subsidiaries are not responsible for any of the content contained in this information asset.

Read more about:

ResearchYou May Also Like