December 20, 2017

The crop protection industry is moving to bulk product handling in the United States. Yet, there are still many times when a jug is the most efficient delivery vehicle, especially when you’re using smaller-volume products. But with jugs, you often end up with half-filled containers you want to use.

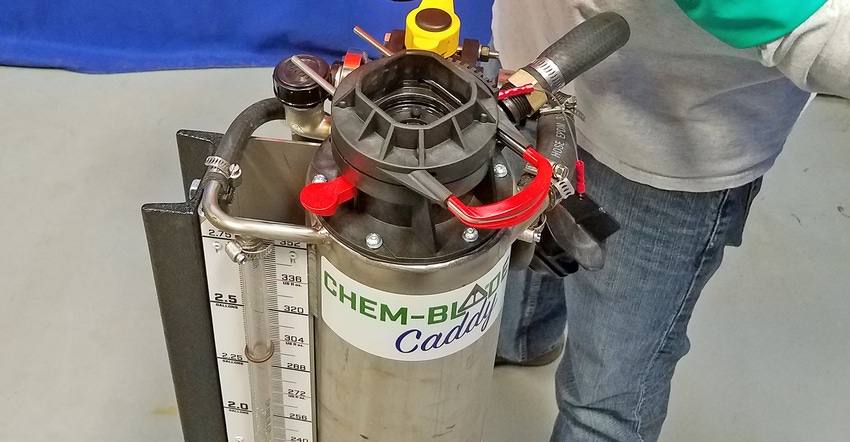

Ethan Eck, inventor of the Chem Blade system, has developed the Chem Blade Caddy, which provides a way to accurately measure crop protection products as you empty the container — no guessing how much you’re putting into the tank.

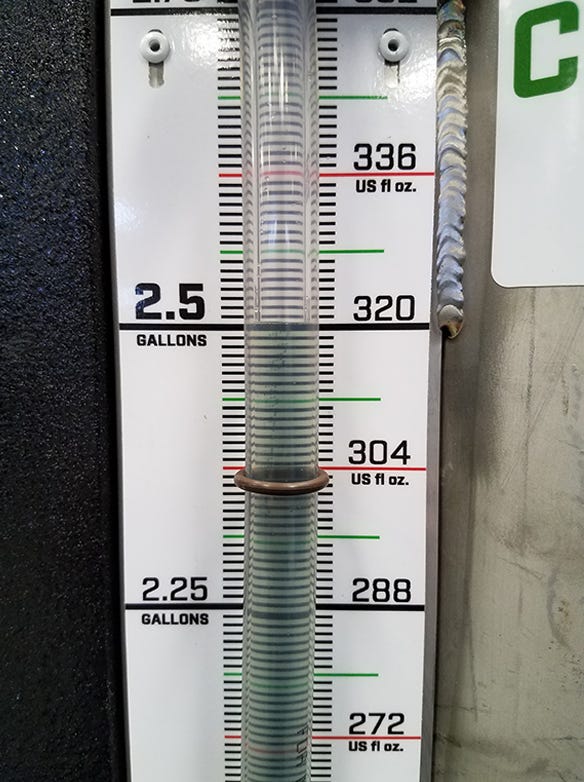

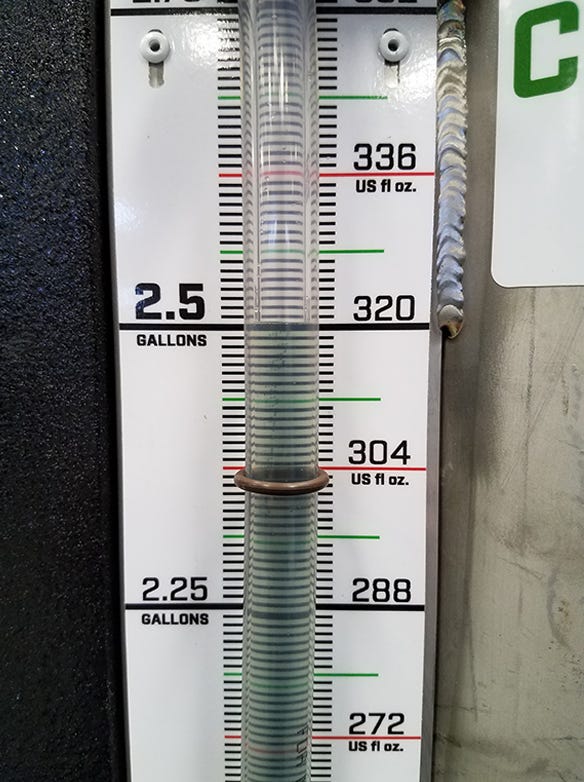

With the system, the operator can safely transfer partial amounts out of jugs, with a measuring accuracy down to the single ounce. Currently, the industry standard is to use oversized measuring cups, but this new system is more accurate and offers the benefits of a closed-system design.

Many operators don’t take the time to accurately measure in the heat of application season, doling out product at levels they feel are right for the field, Eck says. “With field sizes, sprayer sizes and application rates not always being a mathematical match, partial dosing is a necessity,” he says. Accuracy pays when a gallon of newest-tech product can cost as much as $8 an ounce.

CLEAR MEASURE: The Chem Blade Caddy is a tower with a graduated gauge so users can measure material to the nearest ounce, increasing precision and saving material. It helps spray applicators maximize use of crop protection jugs.

A closed-system approach

The first step is to have an interface between jug and system that prevents the product getting on the operator. The Chem Blade Caddy is designed to work with the easyFlow System, which is available from Greenleaf Technologies. The system includes a special cap that goes on the jug, and an interface for that top to the caddy system.

They system itself is placed in line for the spray tank supply system and connects through simple plumbing, Eck says.

The top actually has teeth that cut into the jug seal and then remain in place for delivering product. The cap has a retaining system to keep the jug seal in place, so it doesn’t end up in the tank. This creates a closed system, where all the operator does is take off the cap, screw on the easyFlow top and is then ready to dispense crop protection products.

The caddy releases the jug contents by a special lever. Material flows into the system, and a clear-view tube shows the amount of material going into the system. Hit the number of ounces you need, and all you do is close the lever. You can remove the jug and set it aside for using the rest of the product in a different load.

The second step is moving product into the spray tank. Eck explains that once you’ve hit your desired amount, simply have the venturi (a short tube that tapers in the middle to increase a liquid’s flow) of the Chem Blade Caddy system draw material into the sprayer’s tank. “The venturi will shoot material through suction into the tank,” Eck says. “And when it’s not sucking material from the tank, the venturi provides back pressure that can be used to pressurize water to rinse the inside of the Caddy and the jugs to keep them clean.”

Dealing with partial jugs just got easier. You can learn more about the Chem Blade Caddy by visiting chemblade.com; you’ll also find videos there showing the product in action.

About the Author(s)

You May Also Like