June 5, 2019

When John Deere launched the S700 Series combine, the first thought for those on hand was that the machine’s exterior was little changed from its predecessor. For that new machine, the big changes were “under the hood,” with new software and systems to manage harvest under wider conditions and collect date more precisely.

For model year 2020, John Deere is updating S700 Series systems in the machine to improve automation, data management and residue placement.

First up is Combine Advisor, a system that uses ActiveVision cameras and sensors to identify changes in crop conditions, and automatically adjust the combine to maintain the operator’s settings for best performance as conditions change.

Said Matt Badding, harvest product manager, commenting in the media announcement launching the upgrade: “In addition, the user interface has been improved, simplifying control for the operator.”

Another feature, HarvestSmart feed-rate control, regulates ground speed during harvest and adjusts settings on the go while it maintains consistent crop load and responds to crop variations. That system has been updated to enable the combine to run closer to its power limit. That’s done by analyzing engine power, load and rotor pressure to gain best efficiency.

The HarvestSmart user interface has also been made more intuitive, and the 30-second calibration process is now passive. That means no wait time is needed for calibration to finish. Badding explains that this feature is like the auto industry’s adaptive cruise control.

“Operators no longer have to speed up, then slow down to set a target speed,” he says. HarvestSmart is standard on S700 Series combines equipped with the ProDrive transmission.

John Deere has also replaced the S700 Series combine moisture sensor, updating it with a new version offering improved accuracy and higher-quality data.

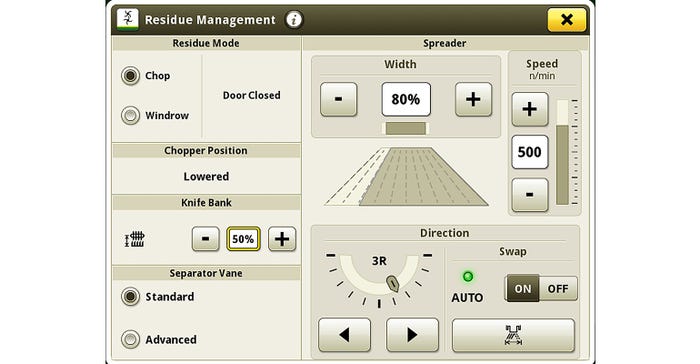

MANAGE RESIDUES: The new Auto Swap function will automatically switch direction of residue 180 degrees when the combine turns a headland, allowing material to redistribute in the other direction.

Residue management upgrade

Managing the rising amount of residue coming through a combine has become more important these days as crop yields rise. For the S700 combine, an optional feature allows the operator to set the chopper knife bank in four different positions without leaving the cab. Badding explains this is another time-saver during harvest, especially when switching between crops.

“This adjustment is now integrated into the Optimize Performance crop settings in the Generation 4 Display. Default settings are based on crop type, but can be easily adjusted to fit a customer’s specific needs,” he says. “Settings can be saved for future use; so the next time a switch is made from soybeans to corn, it will automatically default to the last setting entered for that particular crop.”

Auto Swap is another setting that’s now standard. It works with PowerCast and Advanced PowerCast tailboards to make residue placement more precise. Once the operator sets the combine’s residue offset to compensate for a crosswind and activates Auto Swap, the combine automatically swaps the direction of the residue 180 degrees as it turns on a headland and then redistributes material in the other direction.

Badding adds: “It may seem like a small improvement, but this automates a task a combine operator might make dozens of times each day, depending on conditions.”

All S700 machines for model year 2020 also come standard with an expanded Precision Ag intelligence package. In addition to the existing integration of Generation 4 CommandCenter displays, AutoTrac and documentation, customers now get JDLink with five years of connected service. With JDLink, the user can easily transfer data and remotely monitor machine performance.

The height of the combine’s auger has been increased to accommodate today’s taller grain carts, which Badding adds is “especially beneficial to operators who unload grain into grain carts on the go or in unfavorable conditions, such as while crossing waterways or other low spots in the field.”

Learn more about the upgrades at johndeere.com.

Source: John Deere. The source is solely responsible for the information provided and is wholly owned by the source. Informa Business Media and all its subsidiaries are not responsible for any of the content contained in this information asset.

You May Also Like