Think DifferentNitrate management in tile water is a big reason why this water control structure has slowly gained a foothold in the Corn Belt, but its potential for providing timely water to corn and soybeans may spell the future for this underground tile water management tool. Some see the day when hundreds of thousands of acres of tile-drained land will use smart drainage systems to supply water as well as drain it away.

June 23, 2015

Concern about nitrogen in tile waters that leach from farms, overloading local water supplies and creating hypoxia in the Gulf of Mexico, have spawned newer underground nitrogen removal practices. Bioreactors, saturated buffers, small wetlands and drainage water management all result in less nitrogen flowing from the farm through underground tile.

The workhorse component of each practice is an underground water control structure that can regulate water levels, direct water into the soil or use a nitrate filtering practice. The use of this tool is likely to increase in the future.

Two water control structures work in tandem with bioreactors. One at the inlet, or upstream side of the bioreactor, intercepts a tile line and directs water into a bed of buried wood chips. A built-in bypass allows some or all the water to bypass the bioreactor as needed. A second water control structure at the downstream end of the woodchip bed controls the level and flow speed of water in the bioreactor.

The concept is similar but with a twist in a saturated buffer. The water control structure intercepts high-nitrate water from field tile that had previously emptied directly into a small stream and directs it into perforated tile in a streamside buffer. The perforated tile disperses the water into the soil, allowing grass and tree roots in the buffers to absorb the nitrates.

In small constructed wetlands, a water control structure works as an adjustable outlet for waterfowl management and other wetland functions.

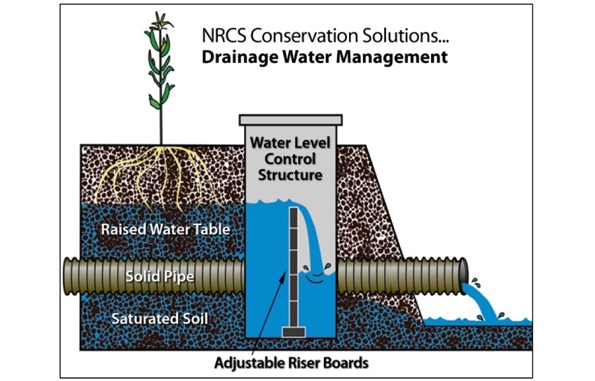

The practice that really has Charlie Schafer, manufacturer of the water control structure at Agri Drain in Adair, Iowa, revved up is drainage water management. An inline water control structure installed at the edge of a field intercepts a tile line, raising and lowering water levels in the soil as the crop needs it. Ahead of planting, all stop-logs are removed, completely draining the field. After planting, stop logs are reinserted to raise soil water levels as rainfall infiltrates the tile. The water and nitrates are then available to the crop during the growing season. If rains are exceptionally heavy, the stop logs can be removed to prevent ponding. Before harvest, the stop logs are removed again to dry out the soil. After harvest, they can be reinserted to capture winter moisture.

Sub-irrigation potential

Research by Iowa State University from 1948 to 2010 shows that more than 60% of crop yield reduction occurred in soil that was too wet or too dry, Schafer says. “Farmers have tiled for years to drain wet soils, and now they’re beginning to see that the same tile can be used to put moisture back into the soil profile in dry times.”

A review by Kieser and Associates, an environmental science and engineering firm, concludes that yields can be improved with drainage water management when the growing season alternates between wet periods and moderately long dry periods. Costs of $88 an acre for new installations and $93 per acre for retrofits could be recovered in as little as four years with a 5% yield increase, the review showed, and two years with a 10% yield increase.

The review found 7.2 million acres of corn and soybeans in the Midwest are suitable for drainage water management. Because it holds water in the soil longer, it also reduces total nitrates delivered to off-farm water bodies.

An inline structure can range in cost from $500 to more than $2,000; water gates are $600 to $750 each, depending on size. One structure can control water on 10 to 20 acres. “Technical service providers can design these systems, the EQIP program helps pay for both design and installation and drainage contractors can install them,” Schafer says. “Once you get them in, those structures just sit there and work for you.”

Agri Drain also offers more sophisticated control structures with valves that can be opened and closed remotely via smart phones and desktop computers. “You can set the water levels day by day with these solar powered systems,” Schafer says. The systems are especially well adapted to active sub-irrigation systems in which stored water is put into tile. All structures can also be equipped with monitoring equipment to manage and record water levels and flow rates. Schafer calls this “smart drainage” and envisions the day it will be the basis of a water quality trading program. See more online.

How water control structures work

There are a number of variations and sizes of water control structures, which use removable stop-logs to control the water level in a practice or in the soil. Some control water levels by redirecting flow and others by reducing flow. The basic structure may serve as an outlet or inlet to a nitrate reducing practice, or both.

The inline structure is connected directly to an underground tile line. Water flows from upstream tile into the center of the small structure, where a series of stop-logs are inserted above ground. The number and height of the stacked stop-logs varies according to the water level desired at a particular time. When no stop-logs are inserted, water flows freely. When stop-logs are inserted or stacked, water on the inflow side elevates to that level and backs up to the same level in the soil upstream.

The water gate is also an inline structure, although in a very different way. Float operated, it is completely buried within a tile line. When an inline water control structure or another water gate downstream backs water up to it, the float on a water gate rises to maintain the flow of water to a 12-inch-higher water level in the soil on the upper side of the water gate. The water gate is not adjustable like the water control structure; instead, it is designed to extend the range of a water control structure.

About the Author(s)

You May Also Like