September 22, 2015

Editor’s note: This article is one in a continuing series that looks in-depth at components that make farm machinery work.

Valves, those gated devices that control the flow of fluid, aren’t top of mind for most people — unless you’re Keith Ziegenbein.

Ziegenbein is the co-founder of KZ Valve, a company that makes motorized electric valves. In 1975 Ziegenbein had been applying anhydrous ammonia on his farm when one of the hoses broke unexpectedly. The only way to stop the flow of the hazardous chemical at the time was through a manual shutoff, which would result in exposure.

“Valves at that time were manually controlled by pulling a rope,” explains Robert Stoupa, KZ Valve’s vice president of business development, who recounted the story at the Ag Machinery Conference in Waterloo, Iowa. “So Keith went back to his farm shop and, with help from his brother Kevin, designed a valve that could be remotely controlled from the tractor cab using hydraulics.”

The brothers started to distribute the valve, a first in the ag market, under the trade name Hydra-Halt. Later in 1982, they came out with the first economically priced electric ball valve to give farmers an option to solenoid electric valves.

Many companies make valves, which come in various types. Butterfly, spool, poppet, needle, plug and globe valves are just a few examples. All of them basically consist of a valve body, gate and an actuator that controls the flow of material, whether it be chemicals in spray tanks, water in irrigation pumps or hydraulic oil in tractors. They can be controlled manually, hydraulically, pneumatically, or in the case of KZ Valve, electronically.

Moving to ISOBUS

New designs and technologies have made them smarter, quicker, more waterproof and more precise. One of the newest advancements is ISOBUS control, where valves are linked on a network and controlled by a monitor in the cab. This method controls the flow of fluid more effectively than manual controls.

“Using ISOBUS, the monitor communicates with the electric valve directly, sending it commands to open or close, or open to an intermediate position,” Stoupa explains. “The valve also communicates back to the monitor with its current position and any diagnostic information about problems it encounters during operation.”

Once a device is connected to the vehicle network, the implement controller can easily collect and distribute data, Stoupa says. “With electric valves on the network, the controller has more precise control of chemical distribution,” Stoupa says. “Add this with positional data from the GPS unit, vehicle speed, engine control, spray rates and steering control, and you can see how the monitor can control the amount of chemical with finer resolution and get chemical where it is needed.”

Any mechanical problems can be communicated back to the monitor over the same ISOBUS connection. “The advanced diagnostics will identify and locate problems quickly as well as notify operators of potential issues, all of which reduce costly machine downtime,” says Stoupa. “Innovations in precision farming such as these are what are necessary to meet the growing population demand.”

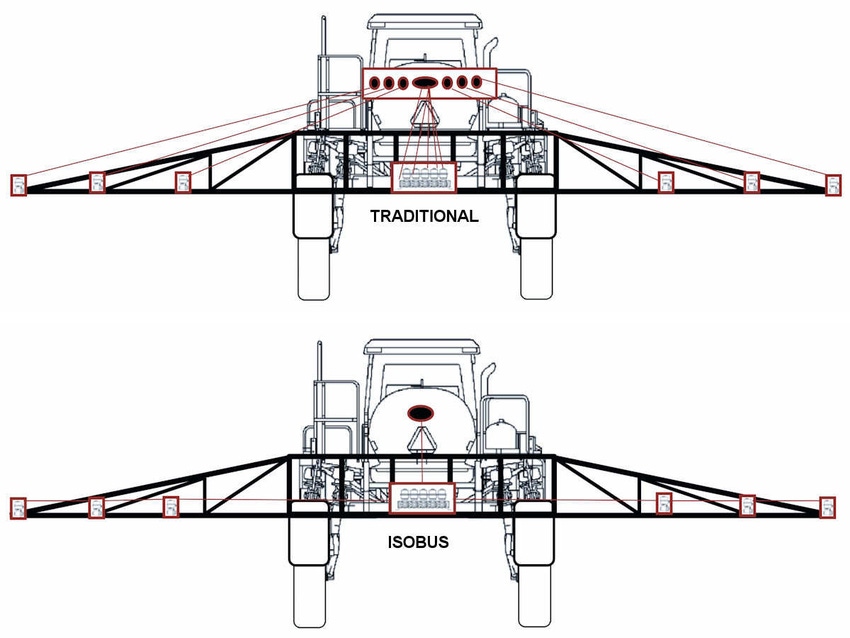

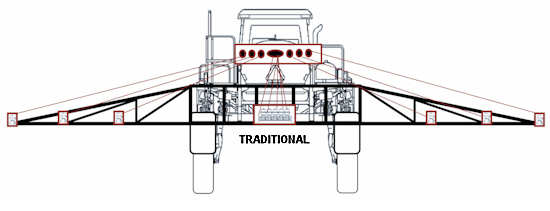

Setup is different between an older sprayer and a new ISOBUS design. With a traditional sprayer above, controls are hardwired from teh monitor to each valve separately.

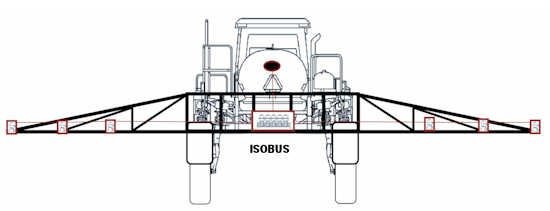

The ISOBUS sprayer lets each valve connect to the network, instead of being directly wired to the monitor. The wiring can be in a daisy-chain along boom sections versus back to the monitor for each valve.

About the Author(s)

You May Also Like