September 18, 2017

By Randy Pryor, Paul Jasa and Jenny Rees

When is getting docked by your grain elevator for selling soybeans over 13% moisture not a bad thing?

When it means your net income actually improves over what it would have been if you'd sold your soybeans at a lower moisture level, for example 9%, to avoid a dockage.

Most soybeans are harvested and delivered directly to an elevator instead of being placed in on-farm storage. Soybeans delivered below or above 13% moisture—the elevator standard—lose potential profit.

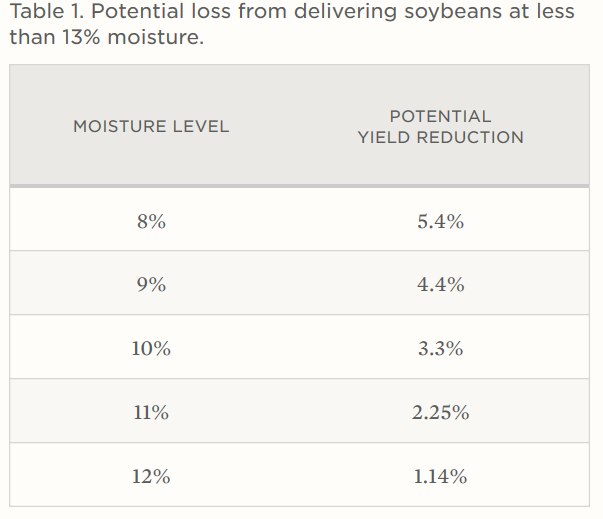

At greater than 13% moisture, there is a moisture dock on the scale ticket for delivering wet beans, resulting in a lower price per bushel. And with less than 13% moisture, profit is lost because there are fewer “bushels” to sell rather than a dockage on the ticket (Table 1). There are fewer bushels because the load weight is divided by 60 pounds per bushel (assuming 13% moisture) rather than by the actual pounds per bushel for the moisture content of the beans at the time of delivery.

What difference does harvesting and selling soybeans at 8% or 9% compared to 13% moisture mean to your bottom line?

If you sell soybeans at 8% moisture, you're losing about 5.43% of your yield; at 9% moisture, it's 4.4%; at 10% moisture, 3.3%; at 11% moisture, 2.25%; and at 12% moisture, it's 1.14% yield loss. That does not take into account additional risk for shatter losses during harvest. For a field that's yielding 75 bu/ac, harvesting it at 9% results in selling 3.3 fewer bushels per acre based on weight because you are not selling the water that you are entitled to sell if the beans were at 13% moisture. With soybeans priced at $9/bushel, that's a loss of about $30 per acre.

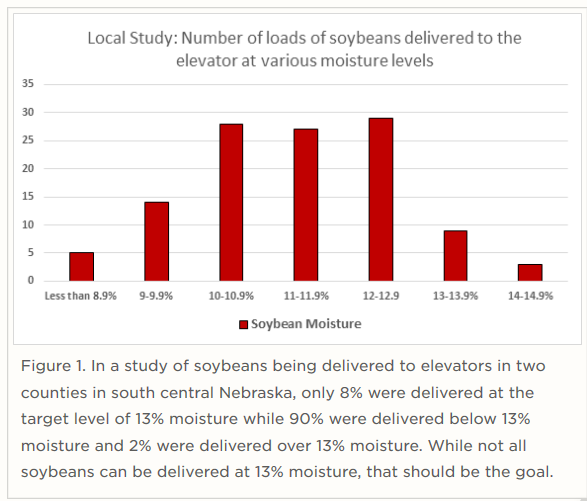

A study of farmer practices was conducted in Hamilton and York counties by former extension educators Andy Christiansen and Gary Zoubek. They collected information from 115 truckloads of soybean that were harvested and being delivered to the elevators (Figure 1). Of those sampled, 5 loads were less than 8.9% moisture; 14 loads were 9-9.9%; 28 loads were 10-10.9%; 27 loads were 11-11.9%; 29 loads were 12-12.9%; 9 loads were 13-13.9% and only 3% loads were 14-14.9% moisture.

For Example

To see how this might work, let's look at a case in southeast Nebraska where a grower is selling soybeans yielding 75 bu/ac. Based on information from a local elevator, growers are docked for soybeans sold at over 13% moisture at the following rates:

13.1% to 13.5% moisture — 1.5% price dock

13.6% to 14% moisture — 3% price dock

14.1% to 14.5% moisture — 4.5% price dock

14.6% to 15% moisture — 6% price dock

Example 1.

If the grower were to sell beans at 13.8% moisture, they would be docked 3% of the selling price of $8.75/bu, reducing the actual price to $8.49 per bushel. Total income per acre would be:

75 bu/ac yield x $8.49/bu = $636.75 per acre gross

Example 2.

If the soybeans were harvested at 9% moisture, there would be 3.3 fewer bushels per acre to sell (4.4% of 75 bu/ac yield due to water loss; see Table 1):

75 bu/ac - 3.3 bu/ac =71.7 bu/ac yield x $8.75 = $627.38 per acre gross

In this example it would be better to take a dockage for selling beans at 13.8% moisture than sell them at 9%. The difference is a positive gain of $9.37 per acre. In practice the grower would likely see an even greater benefit from selling beans at 13.8% moisture due to reduced shatter loss from 9% soybeans.

Originally posted by the University of Nebraska-Lincoln.

Check out how to ensure your equipment is ready for harvesting soybeans at the 13-15% moisture rate.

You May Also Like