There’s more to managing a late, wet soybean harvest than drying soybeans. Consider these eight additional tips from Extension and education experts:

1. Don’t bet on immature, green beans turning color in storage. There has not been adequate research examining if immature soybeans — which are green — will change color in storage. Limited studies indicate that green soybeans will tend to change color but will still have a green tone after storage

Also, there may be a decrease in green color in the oil caused by the chlorophyll, but other oil parameters may not improve.

2. Estimate how long soybeans can be stored. Soybeans that start to mold in the field will have essentially lost their shelf life. They should be dried, preferably with air or very low heat added, then marketed as soon as possible. Oil rancidity will have started and would likely continue.

An initial examination by shelling pods may look worse than justified, however. Often, soybeans that have been weathered or molded in the field will appear somewhat better after a period of aeration.

Surface mold and moldy pods may be removed by the combine. At an elevator or processor, most forms of mold or discoloration will Grade as Total Damage, for which 2% is allowed in U.S No. 1 grade and 3% in U.S. No. 2 grade.

Each market may have an upper limit for acceptance. Crop insurance carriers can explain the effect of quality discounts and field losses on settlements. Be sure to get samples for adjustment purposes at the field, before placing the beans in storage. The always needs to be clear proof of loss in the field.

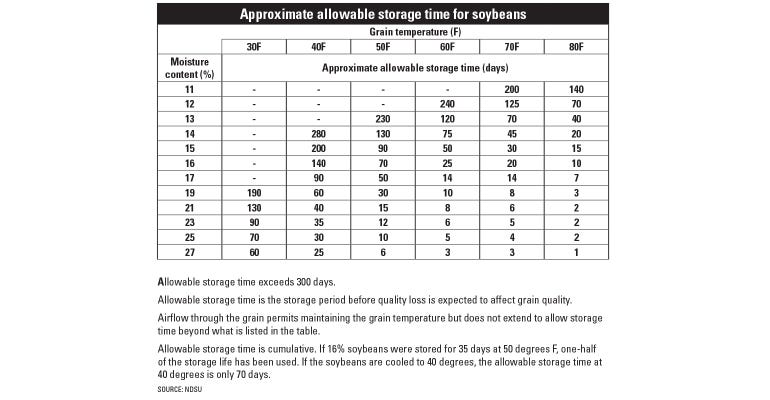

You can estimate storability based on temperature and grain moisture content (see the table).

For example, if soybeans harvested at 15% moisture sit at 60 degrees F for six weeks, approximately one-half of their storage life is used up. If they are then dried to 13% moisture and held at 50 degrees, they have a maximum of 8 months (1/2 times 16) storability remaining before they are likely to drop by one U.S. grade. Generally, soybeans have storage properties of corn that is about 2 to 3 percentage points wetter. Fifteen percent moisture soybeans equals 17% to 18% moisture corn in storage properties.

3. Calibrate your moisture meters Usually, the differences between measurements generated by various on-farm moisture meters are less than 0.25 percentage points. However, wet soybeans are not often tested.

New USDA meter technology used by most elevators and soybean processors is as accurate at high moisture levels as it is at low moisture levels. Compare readings that your moisture meters give you to measurements done by elevators and processors, and then calibrate your meters with them.

4. Recalibrate yield monitors. Yield monitor data can be used for crop insurance, but it is very important to recalibrate the weight measurement every year according the manufacturer’s instructions.

Production records are subject to audit; documented moisture and weight calibration would be part of any audit.

5. Know buyers’ discounts for moisture. If you anticipate delivering lots of wet or damaged soybeans, check closely with your soybean merchandisers about the specifics of their dried weight calculations, and about their damage discounts, which may change quickly.

6. Talk to your crop insurance adjuster if you expect to have quality losses. If you purchased multiperil crop insurance on soybeans, you could be eligible for a quality adjustment. The minimum damage for loss is 8% for soybeans. These are levels that would make the grain Sample Grade (not within the numbered Grades).

An adjuster will likely be assigned, or samples will need to be collected in-field, in the bin and prior to delivery to the market. The in-field samples are the most critical in establishing settlement amounts.

Consider using an official Federal Grain Inspection Service grading agency for determinations.

7. Keep good harvest records. This includes yield monitor (calibrated with documentation) and grain scale date or scale tickets. These records are deemed “soft records” by the Risk Management Agency.

These same records can be used for the Market Facilitation Program payment. Should a crop insurance loss occur, then “hard records” such as grain bin measurements, warehouse receipts, or settlement sheets would be required.

8. Make arrangements to file important paperwork. You’ll need to provide production evidence to your insurance agent as soon as soybean harvest wraps up so potential indemnity claims can be determined.

This same information can be provided to the Farm Service Agency when applying for MFP payments.

Tips are from Ken Hellevang, North Dakota State University Extension agriculture engineer; Charlie Hurburgh, Iowa State University agricultural engineer; Steve Johnson, ISU Extension farm management specialist, and Meaghan Anderson, ISU Extension field agronomist.

About the Author(s)

You May Also Like