December 3, 2013

If you’re looking to update your farm shop this winter, consider changing light bulbs.

Light-emitting diodes, or LEDs, are the newest technology in lighting today. They have been around since the 1960s, and look like the plastic pegs on your LiteBrite set.

You’ve seen them used on exit signs and as indicator lights on electronic devices. Now, due to advancements in the technology, they are bright enough to light up a farm shop. And they can do it at a fraction of the cost of traditional lighting sources.

This 120W High Bay LED Light, with a 7,300-nominal-lumen output, is from FarmTek and can be used in place of a 4,000W HID light for a 90% energy savings. Hang it on ceilings higher than 12 ft. • 120-277 V. $434.95 each.

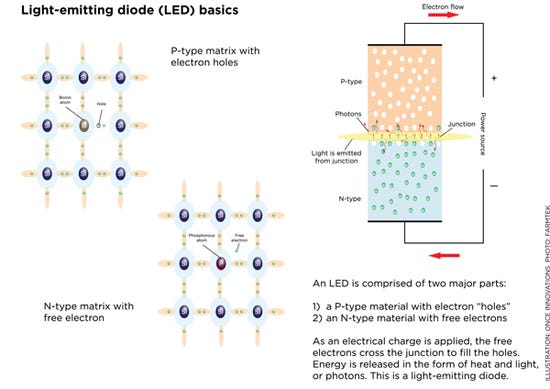

Brian Wilcox, farm lighting consultant and president of Once Innovations, an LED technology company, says LEDs are one of the most efficient light sources available. Wilcox describes them as a “computer chip” that converts electrical energy into light through a process called electroluminescence.

They are 80% more efficient than incandescents, which emit most of their energy as heat, and 30% to 50% more efficient than compact fluorescents, which take a few minutes to reach full brightness. LEDs also have a longer lifespan, in excess of 50,000 hours, which equates to about six years.

The downside of LEDs is they cost more upfront, which is why more farmers haven’t adopted them yet. But lighting experts say those costs will be recouped by the savings you’ll see on your electric bill.

“It’s a no-brainer,” says Zachery Carr, lighting specialists with FarmTek, which sells lights made by Phillips, Sylvania and Infinity, as well as its own private label. He describes some numbers.

Carr says a 400W metal halide light, a typical size used in farm shops, lists for $169.95/fixture on the company’s website. The LED equivalent, a 120W bulb, costs $434.95/fixture, which is a difference of $265.

Like what you’re reading? Subscribe to Farm Industry News Now e-newsletter to get the latest news and more straight to your inbox twice weekly.

“Since watts are an input of electricity, running an LED costs only 30% of what it costs to operate a metal halide light.” He says that at a 40,000-hr. life expectancy, you would pay for the fixture in two to three years. “You’re paying off a fixture a month, basically, and after that, it is all savings to your pocket,” he says.

FarmTek’s 48W LED Wall Light is designed to light up the outdoor areas of your shop in place of a 200W traditional wall light, saving 90% on energy costs. Certified for wet locations, it kicks out 3,000 nominal lumens and has a 50,000-hr. life. • 120-277 V. 60 Hz. $339 each.

The number of lights you need depends on the type of activity being done. The main rule is that the fixtures must be evenly spaced, typically 10 to 20 ft. apart in a warehouse setting, to provide uniform light distribution.

Carr says the common fixtures he sells for farm shops are the high-bay lights for ceilings higher than 12 ft., 4-ft. shop lights and wall-mount lights. Other types include everyday household bulbs and spotlights.

He says the nice thing about LEDs is you can usually use the same fixtures, so all you have to do is switch the bulbs.

Jay Harmon, a professor of agricultural engineering with Iowa State University Extension, says several lighting types are suitable for indoor agricultural applications. Lamps should provide adequate lighting to meet basic needs of the activities within the facility safely. When examining the cost, include upfront cost as well as operational costs, he advises.

Light is measured in lumens, and the higher the number, the brighter the bulb.

To design a lighting system or select bulbs to provide the recommended illumination level, you must know the area to be covered, the lumen rating of the bulb, and the amount of light that actually reaches and reflects from the surface, Harmon says. The type of activity will determine the amount of light needed.

This Two-Lamp Vapor-Tight LED lamp by FarmTek is a “wet location” fixture that can be used for general illumination and high-bay lighting in farm shops. It is designed to be an energy-saving alternative to traditional fluorescent lamps, saving up to 80% on energy costs while taking no time to warm up. It has up to 40,000-hr. life and puts out 1,700 lumens/bulb. • 85 LPW. 120-277 V. 50-60 Hz. $229 each.

As a benchmark, a minimum of 3 lumens/sq. ft. is recommended for machinery storage, 50 lumens/sq. ft. for shop machinery repair and 100 lumens/sq. ft. for more detailed benchwork.

Once Innovations’ Wilcox says all lighting used in agricultural environments is susceptible to moisture and exposure to corrosive elements. He advises farmers to make certain that ag lamps, especially LED lamps and fixtures, are designed for use in their target environment.

“LED lamps and fixtures should have a ‘wet location’ designation for use inside ag environments,” says Wilcox. “This is a National Electric Code Section 547 requirement. With a good mechanical and industrial design, an LED fixture can be made as a ‘wet location’ product.”

This designation ensures the farmer that water intrusion will not be an issue, even water exposure from high-pressure washdowns. A product with an Ingression Protection rating of IP66, IP67 or IP68 will comply with the National Electric Code and protect the light against dust and water issues.

About the Author(s)

You May Also Like