September 29, 2010

Telematic systems that automatically capture and transfer data from farm equipment are coming of age.

After being on the agriculture market for almost a decade, telematic systems that once were thought to be useful mostly to large farming and custom application operations with far-flung equipment fleets are beginning to offer features that smaller operations may find attractive as well.

The newest systems offer remote diagnostics of power equipment, real-time combine monitoring and on-the-go transfer of prescription application, as-applied and yield maps. GPS-based features like current location, field and transport speeds, and idling versus working time also are becoming more sophisticated.

“The original telematic systems in agriculture primarily tracked equipment location,” says Matt Darr, a precision ag specialist at Iowa State University. “They didn’t sell very well because they didn’t add much value. Now [with more sophisticated systems] it is much easier to take specific pieces of information from the machine and transfer the information to someone who can help solve a problem.”

Making money with a telematic system requires persistence and a plan for making use of data, Darr says. “When you buy autosteer, you begin saving immediately,” he says. “With telematics, unless you put effort into using the data, you aren’t going to get much value from it. There is potential there, but you are going to have to go after it. An aggressive producer can make money with telematics, but not everyone will.”

If you want a telematic system with all the bells and whistles, you may end up with a couple of systems in your cab. Systems from equipment manufacturers such as John Deere and AGCO report equipment operations parameters, as well as GPS-derived location and operating status information. Systems that enable on-the-go transfer of field operations data are available from Trimble and Raven. These systems also provide location and operating status information, but operations parameters generally are not available.

Here’s a look at the recent telematic system updates and introductions.

Deere’s JDLink

John Deere pioneered telematics in agriculture when it introduced JDLink Machine Messenger in 2002. In 2009, the company replaced Machine Messenger with two products: JDLink Select and JDLink Ultimate. For 2011, Deere will update Select and Ultimate with a new, more user-friendly Web interface. JDLink also will offer new remote diagnostics and expanded wireless capabilities with an optional satellite module for operation in areas with poor cellular coverage.

JDLink Ultimate will get the biggest revamp. In addition to offering a new remote diagnostics feature, it automatically captures error codes, engine, transmission and hydraulic operating temperatures, and other machine-specific information for qualified Deere tractor and forage harvester models. The new Web interface will simplify setting up custom alerts that can be delivered in real time via text or e-mail.

“For example, you could set a maximum planting speed of 6 mph and be automatically notified when that speed was breached,” says Aaron Bartholomay, Deere senior product development specialist. “Another custom alert could be if a machine idles more than 15 min. This would allow you to reduce idle time and fuel consumption.”

Ultimate’s new Service Advisor Remote feature will allow Deere dealers to remotely access and diagnose a machine wirelessly while it is in the field. For more information, visit www.johndeere.com.

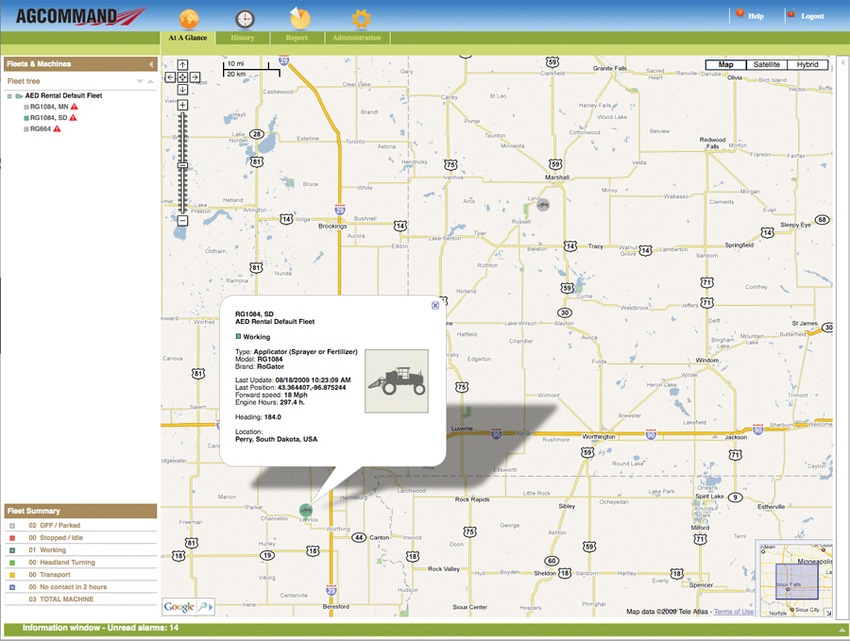

AGCO’s AgCommand

After introducing its entry-level AgCommand vehicle-tracking system earlier this year, AGCO upped the ante this fall with AgCommand Advanced, which monitors combine threshing efficiency on Gleaner, Challenger and Massey Ferguson combines, as well as engine, transmission and hydraulic operations and other functions on AGCO combines, high-horsepower Challenger and MF tractors and AGCO application equipment.

Being able to monitor combine threshing efficiency from afar may elevate telematic systems to a “must-have” system on new combines, says Marlin Melander, technology marketing specialist for AGCO. “The farm operator can be at the bin site and see that grain loss is too high and contact the combine operator to find out what’s going wrong. Reducing that loss could pay for the system very easily.”

The basic AgCommand vehicle-tracking system, which includes built-in GPS, monitors machine location, engine status, hours of work and more. This information is collected and stored on-board and periodically transmitted via a GSM cellular modem to a secure Web site. The operator can view this information on a personal computer or smartphone and receive text and e-mail alarms when machines are operating outside preset parameters. The system also is available for non-AGCO brands via a universal kit.

Collected data can be organized in detailed reports that track engine hours, fuel consumption, operator efficiency, field-specific information and service needs. Users can enable the system for dealer access and notification.

The list price for factory-installed AgCommand is $2,510, which includes a three-year subscription to access to the Web site, cellular communications charges and phone support. The list price for a factory installation of AgCommand Advanced is $4,995, which also includes a three-year subscription. For more information, visit www.agcotechnologies.com.

Raven’s Slingshot

Slingshot from Raven Industries Applied Technology entered the market early this year. It offers cellular-based RTK correction signals plus a brand-neutral, high-speed communications capability that allows it to provide always-on Internet and data transfer services to a wide range of field computers, laptops and other mobile devices.

The Slingshot system includes an application programming interface (API) that will allow software companies, independent developers, precision ag equipment manufacturers, OEMs and others to use Slingshot to deliver solutions to their customers.

The Slingshot Field Hub, which is available in variants for all major cellular networks, is a full-blown router with Ethernet and USB ports, as well as a serial port for delivering correction data to GPS receivers. The system is designed to use the fastest cellular data transfer rates available, including new 4G networks being built by major cellular providers. The hub uses a dual antenna system to reduce dead spots, helping to assure data integrity.

The Slingshot system includes access to a Web site that displays vehicle locations. It also allows users to upload, store and transfer data, such as prescription application files and yield maps, which can be accessed by field and office computers connected to the Internet.

Slingshot’s API — which allows companies in addition to Raven to communicate with Slingshot and Raven or non-Raven field computers — is a first in the agricultural marketplace, says Kelby Kleinsasser, director of ag information for Raven Industries. It is similar in concept to the highly successful approach taken by Apple to allow developers to design and market programs for the iPhone, iTouch and iPad.

“What we are trying to do is provide a platform to develop applications on,” Kleinsasser says. SST Software, which is partially owned by Raven, is the first to use the API to transfer application prescriptions, as-applied maps and other data between SST desktop software and in-cab computers.

The list price for a Slingshot Field Hub is $2,000 plus an annual subscription, which ranges from $750 to $1,500. For more information, visit www.ravenslingshot.com.

Trimble’s

Connected Farm

Trimble expanded its Connected Farm telematics offering in 2010 by integrating Farm Works’ Sync capability into its FmX display and the new CFX-750 display introduced this fall. The system includes a Web-based server that allows users to store and download planned and completed jobs, guidance lines, soil sampling, and scouting maps, application maps, yield maps, and variable-rate prescription maps to the FmX. The synching system also works with a Trimble Juno SC or Trimble Nomad 800XC handheld or any Windows-based computer with compatible Farm Works software.

Data are transferred via cellular networks using a Sierra Wireless modem (available for both CDMA and GSM/GPRS networks). It is also possible to use a WiFi connection for more local automated data transfer.

Access to the Trimble online server, telephone support and software updates are covered under the Connected Farm Update Service Plan at $500/year for a single device. Each additional device connection incurs a charge of $600/year/FmX or CFX-750 display or $360/year/device for Farm Works Mobile. A Sierra Wireless modem lists for $599.

For more information, visit www.trimble.com/agriculture and click on Information Management.

About the Author(s)

You May Also Like