At a recent meeting, farmers had plenty of questions related to planter equipment. Bill Lehmkuhl, a Minster, Ohio, farmer and owner of Precision Agri Services Inc., encouraged questions. He shared his opinions, but also asked farmers in the audience to share experiences. He believes farmers can learn a lot from each other.

Here are some of those questions and Lehmkuhl’s answers:

I’m realizing downforce is important to get proper seed placement and uniform emergence. Can I accomplish it with manual adjustments on my planter? It still uses springs. The problem with springs for downforce is that they’re virtually never set correctly. That’s because soil types and conditions change across the field and row to row. Systems which first came out which controlled downforce across the planter with air bags helped. But the real answer is controlling downforce row by row.

That typically requires investment in a hydraulic downforce system, but it can pay for itself rather quickly through more uniform emergence of corn. There will be some benefit for soybeans, but not as much. Soybeans are more forgiving than corn.

We no-tilled green in 2019, and had some trouble with wrapping on row cleaners. Do we need them in those conditions? Many people are taking them off and finding their planter still performs well. When a cover crop like cereal rye gets tall, wrapping will be an issue. Several no-tillers are finding they can even remove no-till coulters. They’re relying on double-disk openers to penetrate and make the trench. With the correct amount of downforce, many people make it work.

You talk about integrity of the seed trench. Yet I’ve heard you don’t want to be able to find the trench walls when digging behind the planter. How can both things be true? Integrity of the trench refers to double-disk openers maintaining a firm trench until the seed drops into the slot. You don’t want it to collapse or fill with dry dirt until the seed is placed. You don’t want air pockets either.

Once the seed is placed, yes, you want closing wheels to firm in that soil over the seed. You don’t want slick, hard sidewalls remaining. When you dig behind the planter, you should find the seed, but not the trench. Both things are true — it’s a two-step process.

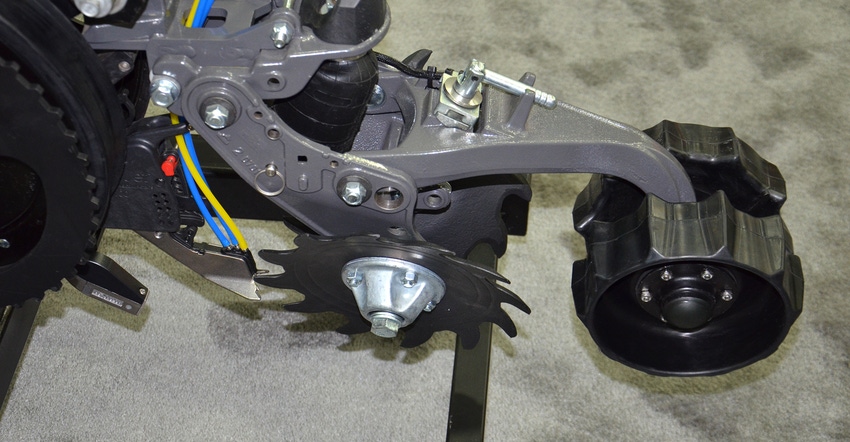

What is the best closing wheel option? That is a question you must answer for yourself in your conditions. There are literally 20 types — types, not brands or individual styles — of closing wheels on the market. There are likely easily 1,200 combinations of closing wheels you could try on your planter. Remember what you want a closing wheel to do: Firm up the seed and take out the sidewalls. There are many good options on the market.

In addition, two-stage closing wheel systems are beginning to appear. Ask questions of salesmen, talk to growers who have tried various options, compare costs versus possible rewards, and choose your best options.

Can soil compaction created behind central-fill planters hurt corn yields? Yes. We did our own three-year study, and we found a 20- to 22-bushel-per-acre decrease for those pinch rows behind the planter. Today’s hydraulic, automated downforce systems which can lift as well as apply downforce may help in those cases.

About the Author(s)

You May Also Like