Southeast peanut producers now experience more cases of aflatoxin than in previous years.

At the recent 2020 Peanut Congress online event, panelists discussed aflatoxin in peanuts that results in discarding the product if aflatoxin levels exceed the specified limit. There is an inevitable cost every year due to aflatoxin in peanuts.

The toxin affects yields, drives costs up and slows production lines in manufacturing plants. The U.S. peanut industry absorbs these costs to ensure that only high-quality peanuts enter the commercial food supply system.

2019 peanut crop

"There is aflatoxin in the 2019 peanut crop, and it's not a pretty picture," said Mike Jackson, president for JLA International. "This is largely due to Mother Nature. It was the perfect storm for aflatoxin in the Southeast crop. The industry is working through the crop, but there will be challenges."

As of May 31, roughly 29.4% of the edible grade peanuts have greater than 15 parts per billion of aflatoxin, failing the USDA specification.

"Most people say there's always going to be a problem with aflatoxin in years that end in 0," he said. "That's true, but we have had more aflatoxin problems in the past decade than in previous years, so it's a continuing and increasing problem.

"We're not seeing aflatoxin issues in the Southwest, so why is it in the Southeast? Extreme weather conditions were one issue. Planting was postponed, and we had moderate or severe drought conditions six to eight weeks before harvest, followed by excessive rain. This created an environment for higher aflatoxin risks."

Rain on later-planted peanuts leads to post-harvest aflatoxin conditions.

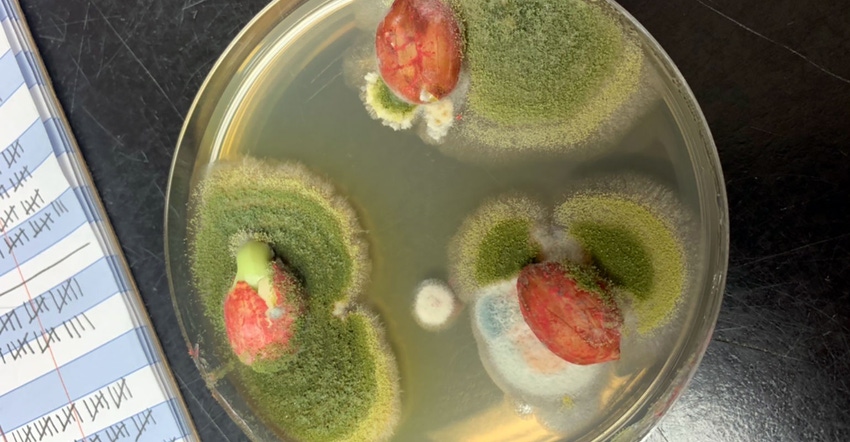

"In irrigated fields, we saw rootworm damage and visible mold," Jackson said. "Over the past decade, the maximum daily average temperature during September and October has been hotter. In 2019, across Georgia from Donalsonville to Statesboro in September, we didn't have any rain. October was the opposite, with over 8 inches of rain in Statesboro."

To handle aflatoxin problems, good communication, planning, and patience are a must to diagnose and minimize high-risk kernels.

"Practices such as slowing down for sorters to be able to do a good job picking out damaged peanuts with aflatoxin is one solution," he said. "Blanching is also a good option. Understand your testing regime and the costs/risks that you are willing to accept."

Sampling is the largest variable in the aflatoxin testing program. Sampling variability can be reduced by considering larger sample sizes. This comes at a cost that must be balanced against risk tolerance, but in a high-risk crop year, supplemental testing makes sense.

"We don't want to forget the consumer, and we want a safe product," Jackson said. "To sum up, there is aflatoxin in the crop, but we can get through this crop despite the challenges."

Eliminating Aflatoxin

"We need to eliminate the start/stop approach that we’ve taken in past with aflatoxin," said Marshall Lamb, research leader and location coordinator at the USDA/ARS National Peanut Research Laboratory. "We push aflatoxin research to the forefront in bad years and move it back during clean crop years, and we have not succeeded and will not succeed with this model. The 2019 crop is proof of that. We need a long-term comprehensive, coordinated approach to eliminate aflatoxin in U.S. peanuts."

Pre-harvest practices such as irrigation could help prevent aflatoxin in addition to increasing yield and grade. Post-harvest practices such as understanding airflow in drying conveyances and warehouses for uniform drying are important, too.

"By understanding incoming moisture in farmer stock peanuts, this can help improve warehouse management and prevent aflatoxin," Lamb said. "Understanding airflow and drying in a warehouse is critical.

"How do we accomplish this? We must work together and coordinate better to maximize resources and impact. We have a lot of promising research, but we need to move faster to get it to the industry. Every year we have this problem, the industry loses a significant amount of money and customers. We need to establish short, mid, and long-range goals, and we need to start now."

About the Author(s)

You May Also Like