"As far back to the 1980s, I had been wanting to grow peanuts," says Mississippi farmer Joe Morgan, "but they were still under the government quota system, and it was hard to buy or rent quota from established growers. We were doing well with soybeans, making good yields, but couldn’t get enough land for it to be an economical crop. Peanuts offered more profit potential per acre."In 1990, M&M Farms was able to get 45 acres of quota and they've been growing the crop ever since — with 800 acres in 2012.

Almost 50 years ago, young marrieds Joe and Patricia Morgan moved to a Forrest County, Miss., hilltop to farm 400 rented acres. “We didn’t have much of anything,” Joe recalls from the distance of decades. My father had co-signed my bank note for my farm loan, and we had a house trailer to live in.”

The land where he would farm, south of Hattiesburg and adjacent to the Desoto National Forest, was hill land once in woods, and he says, “I’d wear out a set of cultivator blades every few days running over stumps in the field.”

But as years went by, improvements were made to the land, acreage was gradually expanded, and today Joe and Patricia have a beautiful home where the house trailer long ago stood; their son, Joe Jr., who farms with them, has a new home just across the road; the hilltop is covered with neat metal buildings for equipment, a spacious shop and grain storage bins, and M&M Farms now encompasses 2,350 acres of land that produces high-yielding crops.

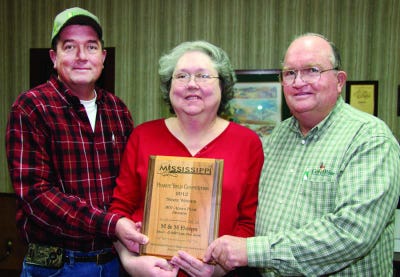

IN THE 2012 yield competition held by the Mississippi Peanut Growers Association, M

In 2012 the Morgans entered the Mississippi Peanut Growers Association yield competition and were the state winner in the 800 acres and above category with 5,660 pounds per acre.

“Patricia and I grew up in Perry County, the next county over,” Joe says. “My father did construction work, and also had a cattle operation and grew small acreages of row crops. Patricia’s father was a farmer, with a large commercial produce operation, growing all kinds of vegetables and also some cotton.”

Joe, valedictorian of his high school class, was going to pursue an engineering career, but he laughingly says “calculus and higher math were my undoing, and I decided to be a farmer.

“I started in 1965 with a little over 100 acres of rented land, using my father’s Allis Chalmers tractor. A tractor salesman tried to get me to buy a bigger tractor, and I told him if he’d find me some more land to farm, I’d buy his tractor.

“He found this land, which belonged to a man in Georgia who owned a lot of land in Mississippi and other states. The owner agreed to let me rent 400 acres and pay him in the fall when I’d harvested my crops. In those days, everyone was growing soybeans, and I grew beans, corn, and wheat.”

Now, M&M is the largest farming operation in a county that no longer has much agriculture — when the government’s Conservation Reserve Program was started, large chunks of land went into pine trees.

“With today’s equipment, chemistries, and varieties, we could easily farm another 1,000 acres,” Joe says, “but there is no land available for farming in this area. To expand, we’d have to go 60 miles southwest, and we’re just reluctant to commit to that.

“From here to the north end of where we farm is about 30 miles, and to the east we go about 12 miles — a lot of fields, ranging from only about 2 acres to the largest, 180 acres. Just moving equipment from place to place is a challenge, particularly on Highway 49, a high traffic route to the Gulf Coast. Even though we have escorts and flashing lights, we’ve still had a couple of instances of people running into our tractors.”

Over the years, Joe says, “We’ve tried a lot of different crops: soybeans, corn, wheat, cotton, watermelons, produce, and for a couple of years we even had 200 to 300 acres of string beans. But that didn’t last; it was too hard to hit the weather window to deliver the crop on the schedule the contractor needed it.”

As far back to the 1980s, he says, “I had been wanting to grow peanuts, but they were still under the government quota system, and it was hard to buy or rent quota from established growers, many of whom were up in the Delta. And if you bought quota, you usually had to buy the owner’s equipment, too.

Peanuts offered more profit potential

“We were doing well with soybeans, making good yields, but couldn’t get enough land for it to be an economical crop. Peanuts offered more profit potential per acre.

“In 1990, I was able to get 45 acres of quota and we planted our first peanut crop. The land had previously been in soybeans, a legume crop that doesn’t rotate well with peanuts, and over 50 percent of that crop had white mold. But we still averaged 3,187 pounds, which was pretty good considering the disease losses.

COTTON HAS BEEN a good rotation crop for peanuts, says Joe Morgan. They added cotton to their cropping program in 1994 and consistently average about 1,000 pounds per acre.

“After that, anytime quota became available, we bought it. The next year, we had 379 acres. At one time, we were the largest quota holder in Mississippi. The quota system was finally scrapped in 2002. For the past three years, we’ve had 800 acres or more of peanuts, with yields above 5,000 pounds, topping out with 1,244 acres last year and a record yield. All of our peanuts are planted on 38-inch twin rows. We mostly plant the GA06 variety, which performs well for us.”

“In 1994, we made a decision that if we were going to grow peanuts, we also needed to grow cotton because of its rotation benefit to peanuts. We knew absolutely nothing about growing cotton, and the nearest gin was 130 miles away at Loxley, Ala. I remembered my father growing it when I was a boy, and the plants would get so tall and bushy I would sit under them for shade in the summer.

“We planted 526 acres that year — and had a traumatic introduction to cotton growing. We had an absolutely beautiful crop, the kind you’d see on magazine covers. About halfway into harvest, it rained for 11 days straight. We couldn’t get modules out of the fields; cotton seed was sprouting in the modules. But we were fortunate: we still averaged 1,058 pounds.

“In 1995, we decided to plant just cotton and peanuts and sold all our grain equipment. Since 2003, we’ve averaged about 1,000 pounds of cotton per acre.

“We either gin at Gaddis and McLaurin Gin at Bolton, Miss., 110 miles away, or Producers Gin at Theodore, Ala., 120 miles away. It’s a long way to go for ginning, and it takes a bite out of our profit, but we want to keep cotton in our mix for the rotational benefit to peanuts.

“We plant mostly Stoneville cotton varieties, but also some Deltapine. We work with Trey Bullock, our consultant, on variety selection.

“We planted only peanuts and cotton until 2007, but when cotton prices got so low we added corn back into the mix. With irrigation, we’ve had good yields, prices have been good, and corn is also an excellent rotation crop for our peanuts.

“We averaged 204 bushels on 597 acres in 2007. The next year, we had a lot of wind damage from a freak 50 mph windstorm and only averaged 151 bushels. Since then, yields have been quite good — in 2011 we averaged 229 bushels and in 2012 we got 226 bushels.

“It’s impressive, the yields we can get from corn these days with irrigation, improved genetics, and proper fertility. But it takes a lot of water, at least two inches per week. In 2011, with corn under our longest pivot, we had 800 hours on the pump engine at the end of the season; it ran almost continuously, week after week.

“We just won’t grow dryland corn any more. A couple of weeks without water at a critical growing stage can ruin a crop. We have nine center pivots that are fed from four wells — some only make partial circles because of the topography and obstacles — and we also have a hard hose system that we feed from a pond. Our longest center pivot is 1,936 feet and covers about 300 acres. We plant our corn on 38-inch twin row, the same as peanuts.”

Five 48-foot diameter storage bins, with 150,000 bushels of capacity and drying capability, allow more harvesting and marketing efficiency, Joe says. Their corn is marketed through the CHS cooperative at Collins, Miss.

Peanut marketing a challenge

Their peanuts are contracted with Golden Peanuts. “They furnish trailers to us, and we deliver to the West Bay buying point at Wilmer, Ala., about 80 miles away. Until 2002, we did our own hauling to Andalusia, Ala., a bit over 200 miles away, but now we have a trucker who does the hauling for us.”

LAST FALL, for the first time in many years, the Morgans planted winter wheat. After harvest, they may put some of the land in grain sorghum or double-crop some to peanuts or cotton.

Contracts vary widely from year to year, he says, and often in the same year. “Peanut marketing is always a challenge, insofar as what kind of contract is offered and for how long. We usually have all our expected production under contract before planting. When peanut prices shot up in 2011 after the Texas crop failure, we were lucky enough to get some of our production contracted at the $1,000 per ton high.”

But with a U.S. surplus from the big 2012 crop, Joe says, it’s expected contract prices this year will drop significantly, although “things may be a bit better than expected as a result of the short crop in India last year and the demand that created in China for U.S. peanuts.”

The Morgans plant peanuts anywhere from late April to early June, but prefer to plant in early May.

“A wet fall is something no peanut grower wants to see,” Joe says. “That can cause significant crop losses. Our soils are classed sandy loam, but they border on the heavy side for peanuts. If the weather’s dry for a month or six weeks, the ground gets so hard we can’t get a digger in it, and if we get a heavy rain, it can keep us out of the field four or five days — you just don’t want to lose that kind of time at harvest.

“The fall of 2010 was so dry we couldn’t dig part of our peanuts. Our landlord agreed to let us pump water from a nearby pond, so we strung aluminum pipe from the pond to the field to run our hard hose system. After applying the water, we were able to harvest our peanuts. We normally get about 30 to 40 acres on a set of digger blades, but that year a set would last only about 7 acres.

“Fall 2012 was wet when we started digging and we were losing peanuts. But thankfully, the rain quit, the weather was ideal, and we harvested our highest yield ever.”

Their most challenging decision with peanuts, Joe says, is determining when to dig. “We badly need a method to more accurately evaluate this. Research on new methods and technology is under way, and we’re hopeful something more accurate will be available in the near future.”

The Morgans follow a strict rotation program for their crops, and he says that even though they’ve been growing peanuts more than 20 years, “diseases haven’t been getting any worse.

“Rhizoctonia limb rot used to be a problem, but our biggest problem now is white mold. We try to follow a two-week spray schedule, as long as weather conditions are favorable for disease development. Sometimes though, weather will interrupt our spray schedule and we can have some yield reduction.

“There are no aerial applicators in this area any more, so we have to use ground equipment or arrange for a spray plane to come down from the Jackson area.’’

With their mild winters, Joe says, “almost every known weed thrives here. Most of our weed problems are behind corn, and morningglory and sicklepod are the ones we deal with most.

“Thus far, we’ve had no weed resistance problems, and no pressures that we can’t handle with available chemistries. We don’t have a lot of pigweeds, but we’re careful to get them out and not let any go to seed. It’s probably just a matter of time until seeds come in from somewhere else and we start seeing resistance.”

Peanuts take a lot of tractor power

In their equipment lineup, they have two Amadas peanut diggers, a KMC flex digger that’s used on uneven land, and three Amadas pickers. Their six-row cotton picker is a John Deere 9996. They’ve been sharing a John Deere corn combine with another grower, but this year plan to buy one of their own.

“IT TAKES a lot of tractors for our operation,” Joe Morgan says. “We need five tractors for peanut harvesting, or six if we have to do any shaking, and for cotton we need three tractors."

“It takes a lot of tractors for our operation,” Joe says. “We need five tractors for peanut harvesting, or six if we have to do any shaking, and for cotton we need three tractors. We’re usually planting and harvesting peanuts and cotton at the same time, so we need a lot of equipment.

“We have eight John Deere tractors, and all but one have RTK guidance equipment, which gives us the precision we need for strip-till. We also have RTK on our sprayer. We usually replace our tractors all at once to take advantage of multi-unit discounts.”

They have four full-time employees and use some part-time help at busy planting and harvest times.

In 2004, the Morgans started using poultry litter for fertilizer, adding commercial nitrogen and sulfur as needed.

“On cotton land, we’ve been applying 3 tons per acre,” Joe says, “but this year we’ll cut back to 2 tons; on our corn ground, we apply 4 tons per acre. Demand for the litter has increased in recent years and it’s getting harder to get.”

Last fall, for the first time in many years, they planted winter wheat, about 800 acres. “It looks like there’ll be good money in it if we can get a good yield,” Joe says. “In the past, we averaged 50-60 bushels, but we quit growing it after a freak late frost caused a big loss. After we harvest this year’s crop, we may leave some of the land out of production or plant milo on part of it, or we may try double-cropping some cotton or peanuts.”

Joe, who has served as president of the Mississippi Peanut Growers Association for seven of the eight years since it was organized, says he “could not have dreamed” as a young beginning farmer that his modest operation would become what it is today.

“We’ve had a good life here,” he says, “and we’ve been blessed to have hung on and succeeded in south Mississippi farming. My philosophy of farming is that if there is any limiting factor, I don’t want it to be something I’ve done or haven’t done; rather, I want it to be something beyond my control — weather or other disaster. We’ve tried to take care of our land and build it up, so we can leave it in better shape than we got it.

“I’m grateful to Patricia for all she has done over the years, and I’m pleased that Joe Jr. chose to farm with us. It has been a joy to have him working alongside me all these years.”

Joe and Patricia have four grandchildren and one great-grandchild. Joe Jr. and his wife, Grace, have two children, and their daughter, Tommy Jean Daugherty, and her husband, John, also have two children.

About the Author(s)

You May Also Like