Precision planting equipment has resulted in more even emergence of corn and cotton crops, regardless of soil type or compaction, and more uniform growth through the season, say Jack Huerkamp and son Brandon, who farm in Noxubee County, Miss. "I've never seen crop stands as even and consistent as we've had this year," says Jack.

Farmers have an amazing array of technology nowadays from which to choose, but says Jack Huerkamp, “You’ve got to be careful to not be so dazzled by the bells and whistles that you overlook the main reasons for buying a system: Will it help me to do my work more efficiently, and will it make money for me?”

Huerkamp, who farms with his son, Brandon, near Macon, Miss., growing cotton and corn, says the money they’ve invested in recent years in new planter technology, a John Deere round module picker, and center pivot systems has met both those requirements.

EXAMINING one of the units on their precision planting system are, from left, Jack Huerkamp, son Brandon, and Vaughn Koehn, Precision Planting representative.

Additionally, they’re founding members/stockholders in the nearby $6.5 million state of the art Bogue Chitto Gin, one of the few new cotton gins built in the Mid-South in recent years.

“We’re always looking for new ideas, better ways to do things,” says Jack, who has been farming in Noxubee County for 36 years.

“The Deere picker was a significant investment, but it’s an extremely efficient machine and it saves a lot of time and labor harvesting our cotton. The money we’ve spent on center pivot systems has also paid dividends. We haven’t had to do a lot of irrigation the last couple of years, thanks to timely rains, but it’s critical that we be able to provide water to our crops when it’s needed, particularly corn.

“On some of our cotton, where we didn’t get rain this summer, we had to make six or seven circles,” Jack says. “We have some dryland corn near the Alabama line that got only 4-5 inches of rain after it was planted, and even so, it yielded 200 bushels. We were really tickled with that. The cool July we had will put a lot of extra bushels in farmers’ bins this year.”

Stay current on what’s happening in Mid-South agriculture: Subscribe to Delta Farm Press Daily.

A technology that has been in evolution for the past five or six years on the Huerkamp farms is a precision planting system.

“We’ve basically rebuilt the planter from the 10-row planter we started with a few years ago,” Jack says. “We’ve made additions each year as the technology has changed and improved. About the only thing original is the planter bar.”

“We’ve got about everything on it that can be put on it,” says Brandon. He laughs: “If Dad decided to trade it for something else, I think I’d put up a fight, after all the work we put into it.”

Planting system components

“WE GET much more accurate spacing and more consistent seed depth,†says Jack Huerkamp of his Precision Planting system. “It gives us an impressively even and uniform emergence, and more uniform crop development throughout the season.†Cotton and corn were planted directly into stubble of a cereal rye cover crop.

The various components are from Precision Planting LLC, a Tremont, Ill., company. Vaughn Koehn, West Point, Miss., who represents the company in the area, says, “The Huerkamps have been involved in a lot of beta testing for us. They’re experienced farmers who’re interested in technology that can help them be more productive and efficient, and we’ve had an excellent relationship with them.”

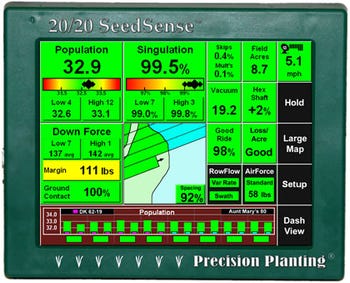

“We started with a 20/20 SeedSense Monitor,” says Jack. “It gives us information on the display unit to show if down force is set correctly, if meters are running at peak accuracy, if we’re operating at optimum speed, if debris is causing skips, and if there is adequate row unit weight to get the proper seed depth.

“After that, we added DeltaForce, which controls each planter unit separately, detecting changes in soil structure and applying the specific pressure needed for that unit to place seed at the exact depth we want. Whether it’s soft ground or packed ground, the sensor detects and compensates, so seed from that unit will be at the same depth as seeds from all the other planter units. This eliminated the air bags we’d previously used on the planter units.

AN ARRAY of monitors provide detailed information about every facet of the Huerkamp planting operation.

“I like 35-40 pounds of actual weight on a hopper unit for lighter ground, but may need as much as 75-80 pounds for heavier ground. With our previous system with air bags, I was constantly having to make changes to adjust planting depth, which was very time-consuming. And seed was placed at an average depth across all the planter units. This system reacts within one-third of a second, according to soil condition, and it then places seed from each unit according to the parameters I’ve chosen.

“It adjusts hopper weight so soft ground isn’t gouged, which can cause hatchet roots. We get a nice even root development all across the field. We can set parameters for heavy ground versus light ground and get exactly the seed placement we want all across the field.”

The end result, Jack says: “I’ve never seen a corn stand so even and consistent as what we have this year.”

They now can also plant at higher speeds and maintain accuracy of seed placement. “With our previous system, we were planting corn at 4.5 to 5.2 mph,” he says. “Now, we can go at 5.5 to 6 mph, and still get consistent seed placement.’

STAY INFORMED about important upcoming events: Delta Farm Press Calendar of Events

They plan this winter to add speed tubes to the planter. “This seed delivery system will allow us to plant corn much faster than with traditional seed tubes, while still maintaining precise spacing and depth,” he says. “Our previous system with air bags would make adjustments in seed placement only every 4 seconds. In 4 seconds, the planter can travel as much as much as 30 feet, and you don’t get consistent, even seed placement.”

Vaughn Koehn says, “With many planters, seed placement is limited by the constraints of the seed tube, because higher speeds generally lead to poor spacing. SpeedTube solves these problems, allowing farmers to plant as much as 2 mph to 3 mph faster.”

Plant more acres per day

THE IN-CAB DISPLAY gives the planter operator instantly updated data on planting progress.

“All this means we’ll be able to plant more acres in a day and get planting completed more quickly,” Jack says. “When you’re coping with uncertain spring weather, that’s important. Running a planter as slow as 4.5 miles an hour is just downright painful. With our previous system, we could plant 125 to 150 acres in a day — now we can do 150 to 175 acres, and that makes a difference.

“This year, we added vDrive, which allows incredibly precise control of plant population, even on curves, and when ground speed changes. There is a 12-volt motor on each hopper unit, which has eliminated chains, bearings, hex shafts, hydraulic motors, clutches, etc. It’s a much simpler system; a 12-volt electric motor on each unit controls that row individually.”

Using FieldView app for the iPad, he says, “We can see a map of what’s happening on each row as we go across the field.

Brandon says, “Yields have been better and better since we’ve started using these precision systems. Yield for any crop starts with the seed and the way it’s planted. Seed companies are continually giving us more and more improvements in seed, and being able to plant those improved seed more accurately helps the crop to emerge more evenly and to develop more uniformly.

THIS YEAR'S corn crop was "the most consistent I've ever had," says Jack Huerkamp.

“Although we operate our own equipment, this technology will also allow a farmer to remotely monitor how a tractor driver is performing — whether he’s going too fast or too slow, or whether the system is being operated efficiently. You may be at another field miles away, or picking up supplies, and it can send a text alert if your driver is operating outside the parameters you’ve set.”

Koehn notes that the system also has RemoteView capability, which allows Precision Planting technicians to access a system remotely to analyze any problems that may occur.

“V-Drive and Delta Force are important in both our corn and cotton crops,” Jack says. “We get much more accurate spacing and more consistent seed depth, which results in an impressively even and uniform emergence, and more uniform crop development throughout the season.

“A lot of today’s agricultural technology is nice, but it may often be more than is needed for a particular operation. This technology makes a significant difference in how a crop emerges and develops, and in the yield we get at the end of the season. It’s expensive technology, but it’s certainly paying off for us.”

Koehn says, “A nice thing about these systems is that you can retrofit planters you already have. You can take an older planter and make these changes and basically have the newest technology.”

Use of cover crops

Being able to obtain a consistent planting depth, regardless of soil and field condition, is a distinct advantage, Jack says. “In recent years, we’ve begun using cover crops more. They are either broadcast with a spin spreader or spread with a Montag with a hipper as we hip rows. In the spring, we burn down the cover crop and plant directly into the stubble, and we can still get precise planting depth and seed placement.

THIS YEAR'S crops were planted directly into a cereal rye cover crop, but the precision planter allowed uniform seed placement regardless of soil type or compaction.

“Cereal rye is our first choice, but we may not be able to get seed this year, so we’ll probably go with oats as our second choice. Wheat would be our last choice. We’ve also used some Austrian winter peas, which worked well.

“With corn, we use modified no-till, and with cotton we’ll rework the beds, but still plant on the same beds. We’ve got beds on our farm that are 20 years old.

“Behind corn, we run a heavy chisel plow between rows, then follow with a bedder. After we get a rain, we’ll run the bedder a second time to smooth off things, and then in the spring we’ll run a do-all and plant. For cotton, we’ll run a stalk puller in the fall, then a bedder with a bit of fertilizer, and in the spring we’ll run the do-all and then plant. Everything is planted on a 12-row pattern.”

This year, they began planting corn in late March and continued through April, with the last field planted May 6. Their farming operation is 1,700 acres total, with 900 of that in cotton this year.

“We try and maintain a 50/50 rotation between the two crops,” Jack says. “We planted this year’s crops into stubble from a heavy rye cover crop and got very even emergence and an absolutely beautiful stand, with uniform development through the season.

“We went heavier in cotton because the price was better at planting time. Unless there is some change in the market outlook, I think there’ll be less corn being grown in the next few years.”

THE NEW Bogue Chitto gin processed 36,000 bales last year. The Huerkamps are among the founders of the $6.5 million facility.

This will be their third season with the John Deere round module picker. Jack’s brother, Joe, and his son, Tyler, also have one of the Deere pickers. “There are about 10 of the round module pickers that will be sending cotton to Bogue Chitto Gin this fall,” Jack says. The gin will also be in its third season of operation.

“Bogue Chitto ginned 36,000 bales last year, and we’re expecting an increase this year,” Jack says. “Cotton acreage in our county is up, we’re expecting good yields, and we’ll be bringing in cotton from a wider area.

Cotton has a long history in Noxubee County. At the turn of the last century, before cotton moved to the Delta, it was the leading cotton county in Mississippi, and the county’s yields still rank with the state’s highest.

Last year, Brandon averaged was 1,637 pounds overall, and Jack averaged 1,460 pounds. It was “just a really great cotton year,” they agree. Corn was equally outstanding: Brandon averaged 184 bushels and Jack 172 bushels.

Center pivots fed from ponds

Brandon’s land is about 90 percent irrigated, Jack’s around 70 percent. Between them, they have 13 center pivot systems, all irrigated from ponds, which are supplemented, as necessary, with well water. They also have a small amount of flood-irrigated acreage.

“We can monitor the operation of the pivots by cell phone or iPad,” Brandon says, “and several of them we can control remotely. We installed our first system in 1991 and have been continually adding more.”

He says they can harvest their corn crop in about 10 days if they have good weather and can work straight through. “We have probably more combine capacity than we need right now, but there’s value in being able to complete harvest quickly.”

"WE'VE GOT rows on our farm that are 20 years old," says Jack Huerkamp of their modified no-till system.

Their cotton is late, he says, and it will probably be late September before they begin harvesting. “It looks like a good crop, if there are no setbacks. We have some plots for Deltapine each year, which allows us to get an advance look at varieties they have in the pipeline. Deltapine is just great cotton, and we’ve been really pleased with their varieties over the years.”

Jack and his brother, Joe, trace their farming ancestry back to their great-grandfather and grandfatherin Germany. “Our great-grandfather came to Ohio from Germany in 1872, and my father, who later had a small farming operation there, came to Noxubee County when I was six years old,” Jack says. “I grew up in farming. After I got my ag econ degree at Mississippi State University, I came back to the farm in 1978, and that’s what I’ve been doing ever since.” Brandon, also an MSU ag econ grad, came back to the farm after graduation.

“Noxubee County has many forward-thinking farmers, who are on the cutting edge of developments in agricultural production and technology,” says Vaughn Koehn. “Almost all are owner-operated farms, and they are really interested in technology and how to get the best value from it.”

That interest is reflected, he says, in his ranking No. 6 in the nation among Precision Planting’s representatives last year, and No. 1 in the Southeast three years running.

About the Author(s)

You May Also Like