Whether it’s land forming and straight levees to increase efficiency of water handling, reduce pumping costs, and conserve water, or buying seed, fertilizer, and fuel in bulk to reduce handling and save money, or utilizing smart phones and laptops in the field to save time and money, Abbott Myers and his son, Ransom, make efficiency and long-term planning guiding principles for their 6,700-acre grains operation at Dundee, Miss.

For Abbott Myers and his son, Ransom, efficiency and long-term planning are guiding principles for their 6,700-acre grains farming operation at Dundee, Miss.

Whether it’s land forming and straight levees to increase efficiency of water handling, reduce pumping costs, and conserve water, or buying seed, fertilizer, and fuel in bulk to reduce handling and save money, or utilizing smart phones and laptops in the fields to save time and travel, “We’re constantly looking for ways to do things better, with an eye to the bottom line,” says Abbott.

“Everything we can do ourselves, we do. We hire no consultants, we do most of our mechanical work ourselves unless it’s something major, and we replace equipment only when we feel it’s a sound business decision — we’ve got some power units with over 30,000 hours on them and no major problems, and we’ve got a 20-year-old planter we’re still using.

“Everything we can do ourselves, we do. We hire no consultants, we do most of our mechanical work ourselves unless it’s something major, and we replace equipment only when we feel it’s a sound business decision — we’ve got some power units with over 30,000 hours on them and no major problems, and we’ve got a 20-year-old planter we’re still using.

“Ransom and I have worked out plans for where we want to be in five years, and 10 years, and we have schedules in place for ongoing land forming and other improvements.”

He laughs and admits to one bit of self-indulgence. “Last year, I bought my own combine. We had two, but I love to combine our crops, so Ransom agreed that I could buy one of my own, and it has certainly increased our harvesting efficiency.”

The Myers farm, located in south Tunica County, is spread out over several miles, and soils are heavy buckshot clay.

“We’re fortunate,” says Abbott, “that all of our acreage is pretty much large, contiguous fields, so we don’t have to do a lot of moving equipment from one place to another. In one area, we have 1,000 acres of contiguous rice, which facilitates efficiency in planting, spraying, and harvesting.”

Their crop mix this year, Ransom says, consists of 2,000 acres of rice, 4,000-plus of soybeans, and the balance in corn.

“Our rice is all RiceTec hybrid varieties. Their Clearfield varieties, CLXL745 and CLXL729, have done well for us — the hybrid yields have been better than conventional varieties, though there have been some milling differences. Our non-Clearfield varieties are RiceTec XL723 and XP753.”

They plant as many as 20 different early Group IV and Group V soybean varieties, mostly Pioneer, Ransom says.

“These have worked well for us in recent years. We base our selections on our own production experience and on Mississippi State University yield data. We missed our prime planting time this year because of weather, and got planted a bit late.”

During all the spring flooding, they had some backup water from the Coldwater River and had to replant about 500 acres.

Dropped cotton for corn, more rice

“We rotate our bean and rice ground,” Ransom says, “and have been including corn in the rotation since we got out of cotton about six years ago.”

The move away from cotton, which had been grown on the farm going back for four generations, was Ransom’s idea, Abbott says.

“It has proved a great decision for us, given the strong grain prices in recent years. It allowed us to add more rice and to start growing corn, which has been beneficial for weed control and for helping build up the soil.

“The best cotton crop we ever made was 850 pounds — and we still didn’t make any money, plus there were always conflicts with labor for our other crops. On these heavy soils, I just don’t see us going back to cotton.”

Two of the best things that have happened for farming buckshot ground, Abbott says, “have been glyphosate and oversize tires on farm equipment. Our tractors are mostly John Deere, equipped with dual wheels on front and big flotation tires, and one has tracks. Our combines are CaseIH 8120s, two with flotation tires and one with tracks.

“We have a new Great Plains 3PYP 40-foot planter that drills 15-inch rows. It came with one wheel on the front and we added another. It is very efficient and very accurate. We also have a Great Plains drill that we use for rice and beans.

All of today’s equipment is so much more versatile and reliable than in years past.

“We used to have to disk a lot of land; now, we plant everything we can minimum-till and no-till. We get better yields, need less equipment, use less energy and labor, and again, it’s more cost-effective. Behind corn and where we’re irrigating, we’ll apply Valor in the fall, then an application of Valor and 2,4-D in the spring, and plant.

“On our heavy soils, there is a much smaller window for planting, and when the ground is ready we have to be ready to go; we can’t wait.

“We buy everything in bulk: seed, fertilizer, chemicals, fuel. There is less handling and transporting — it’s much more efficient and cost-effective to get a truckload of seed than an equivalent number of bags, which cost more and then have to be disposed of.

“My father, Ransom A., had been planting on 38-inch rows, but the crop never would close up, so he changed to 30-inch rows in 1972. Where we can’t water, we broadcast beans on 10-inch rows.”

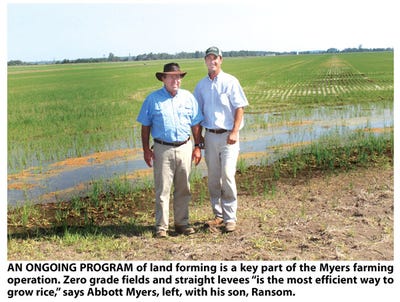

Abbott says his father began land forming his cotton land in the 1960s.

“Over the years, we’ve continued a systematic program of putting land to grade. In most instances, we move less than 1,000 yards of dirt per acre. In some places, as the land settles, we’ll have to come in and reform it.

“About 1,000 acres of the rice land is zero grade with straight levees, which is the most efficient way to grow rice. It uses much less water — there’s just no waste — and water is much easier to control. We can do all our fertilizer and chemical applications with ground equipment, you don’t have all those gates to contend with, and at harvesttime it cuts as easily as a wheat field.

Much greater efficiency of water use

“The way we used to grow rice was very labor-intensive; with zero grade and straight levees we’re much more efficient. The work my father started all those years ago has really been beneficial to us, and Ransom and I want to continue to make the land better for the generations that follow us.

“We catch all the rain that falls and we have tailwater recovery systems — rice loves that warmer water. We’ll average about 1.2 acre feet of water on rice in a season, compared to 3.5 to 3.8 acre feet for conventional levee fields. And there is a significant energy savings for pumping water; we’ll fill a diesel tank only one time, assuming we get some rain during the season. The air-cooled Deutz power units we use are very reliable and very fuel-efficient, a major consideration with today’s high energy prices.”

Power units are electric wherever electricity is available; they are more cost-effective than diesel, he says.

“Irrigation on our buckshot soils is not an exact science,” Abbott says, “but with water we can grow very productive grain crops. We’re blessed with abundant water at only about 14 feet, and can easily pump 2,500 gallons per minute. Also, there are a number of bayous and sloughs running through our farms, and where we can, we pump from them.”

Most of their irrigated land is either flood or furrow, Ransom says, but they also have two center pivots; one covers about 200 acres of beans, the other 200 acres of corn.

“One was badly mangled by a recent tornado,” he says, “and is currently being reworked.” The same storm put sizable dents in a couple of grain bins, broke restraining clamps on one and lifted it an inch or so up from the foundation.

Ransom maintains water on the zero grade rice fields during the winter and leases out duck hunting pits. This has been very popular and generates additional income.

Harvesting of corn starts about mid-August, rice about the first week of September, and soybeans the last of August or first of September.

They have 480,000 bushels of capacity in on-farm grain storage bins, but Abbott laughs, “No matter how much storage we have, we always need one more bin. We store all our rice and some of the corn. We don’t have any 18-wheelers; we have only 10-wheelers to bring grain in from the fields. We contract all of our grain hauling — we don’t want to tie up our people driving trucks.”

They have six full-time employees, most of whom have been with them for many years.

He says “We’re great believers in co-ops, and we market our rice through Producers Rice Mill. Ransom handles marketing of the soybeans and corn.

A family farming operation

The Myers operation is “truly a family farm,” Abbott says.

“My great-grandfather had farmland near here in Mississippi and Arkansas and my grandparents farmed here. My grandfather built the house my wife Sheryl and I live in now. My grandmother raised chickens, turkeys, and ducks out back and sold eggs, and my grandfather looked after the crops. Ransom is the fifth generation of our family to farm.”

But, farming is not what Abbott had in mind when time came for him to go off to college.

“I had worked on the farm for my father — it was hot, sweaty work, with long days, and it was not my dream of a career. I’d always been interested in aviation and went to Mississippi State University with the goal of becoming an aeronautical engineer.

“While there, my father had a detached retina which required that he be inactive for a lengthy period. He asked me to come back and run the farm. I did — and I made the biggest mess you could ever imagine!

“Cotton was our main crop, plus some soybeans. I got the beans planted late (we had almost no herbicides in those days), tried to look after the cotton, had to handle payroll and everything.”

He laughs. “I quickly found out how much I didn’t know about farming. But I also found out something else: I liked being boss and making decisions. I talked with my father and told him I wanted to farm after I finished school. I had expected a reaction from him one way or another. But he, a member of the World War II Greatest Generation, just said somewhat stoically, ‘All right,’ and that was it.

“Years later, my mother told me that he had been very excited by my decision and that he’d told everyone in the family how proud he was. But I didn’t find it out for 20 years.”

Abbott went back to Mississippi State, switched to agricultural engineering, and received his degree in 1972.

“I married Sheryl, whom I had met while in school, and we came back here to live in the house that had been my grandparents’ and my parents’. We’ve been here ever since.”

Ransom earned business and financial management degrees at the University of Mississippi, came back to the farm eight years ago, and he and his wife built a house adjacent to his parents.

“Our daughter, Kathy Bourne, an attorney, and her husband live at nearby Tunica, so all our grandchildren are close by,” Abbott says, “and of course we love that!

“Ransom is a full partner in the farming operation, and we make all our decisions jointly. I made 32 crops with my father, and I know how difficult father-son working relationships can sometimes be, but Ransom and I work well together … although [laughs] sometimes Ransom may not think so.

“My grandparents had 600 acres when they were farming here, only about half of which was cleared. My father was able to add to that during his farming years, when I came back we were able to grow some more, and Ransom and I have continued the growth.

“Most of our land is owned, although we rent some. We’ve been fortunate over the years to buy land when it became available — thanks to the Federal Land Bank. My philosophy has always been, whether you buy your land or rent it, you still pay for it ... and I’d rather buy.”

For the past eight years, Abbott has served as chairman of the Mississippi Land Bank, which serves 32 counties in north Mississippi. He is also a Staplcotn member — “our relationship with them has been very good for our family” — and a member of the Coahoma Electric Power Association board.

“We’ve been through good times and bad times,” he says, “but farming has been good to us and the Lord has blessed us. We’ve also been blessed by the hard work and dedication of those family members who went before us, and by farmer friends such as Dutch Parker and Noel Cannon, who have been generous with advice, and the late Paul Battle, who encouraged me to look at things in new ways and to try doing things differently.

“One thing you learn in this business is to always keep and open mind and an open heart.”

About the Author(s)

You May Also Like