Expenditures for additional grain bins, center pivot systems, a new grain dryer, trucks and trailers to haul grains — and possibly a new module builder cotton picker — are investments that allow Mike Graves and his sons, Allen and Tyler, to increase efficiency, boost yields, and reduce costs on their 4,500-acre Mississippi operation.

Mike Graves and sons Allen and Tyler have spent a lot of money in recent years on additional grain bins, center pivot systems, trucks and trailers to haul grain, and other equipment — and they’re considering the purchase of a new module builder cotton picker.

But, they see these expenditures as investments that allow them to increase efficiency, boost yields, reduce costs, and importantly, free up more time for family, community service, and other activities.

And with 4,500 acres of corn, soybeans, cotton, and wheat on their farms near Ripley, Miss., time is a commodity to be carefully managed.

“We’ve got probably 100 fields,” Mike says. “They range from as small as one acre to the largest that’s 140 acres. But they are mostly all contiguous, along the Tippah River bottom, so we’re not spread out all over creation.

“Our bottomland soils are as good as any Delta ground from a production standpoint. If we get enough rain, it’s no problem to make 50-bushel beans and 150-bushel corn. Three years ago, we averaged 165 bushels on our corn and 1,000 pounds of cotton. We’ve got only about 200 acres of less productive hill land.”

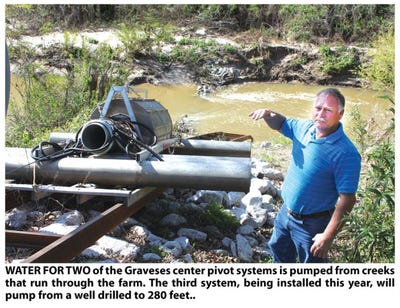

By adding center pivot systems, the Graveses have achieved even better yields. With a new 103-acre system now being installed, they will have three pivots, all Valley, in operation this year, watering about 400 acres. Two are fed from creeks, the new one from a well drilled to 280 feet.

The new pivot could have watered 107 acres, Allen laughs, “if Dad had agreed to cut a big oak tree on the edge of the field.” Mike responds: “That tree’s nearly a hundred years old and has always been ‘eating lunch tree.’ I just didn’t have the heart to cut it.”

Corn under the first pivot they installed brought a 75-bushel yield increase, Mike says. “With that kind of yield bump and good corn prices, we figure we can pay for a pivot in three years, compared to the normally-projected payback of five years.

“Last year, soybeans under our second pivot had a 20-25 bushel yield increase. We’re going to try cotton under one of the pivots this year to see how much irrigation will improve yield. We hope to see as much as a bale per acre increase.”

“We’re looking at adding a pivot every year over the next five or 10 years,” Allen says. “My brother, Tyler, has drawn circles all over our aerial field maps where systems could be located. We figure we can install 50-acre pivots and make them pay, even with relatively low water volume. With our field configurations, the most we could water would be about 1,500 acres.”

“Last year was quite dry,” Mike says, “and we pumped a lot of water. The diesel engines on the 200-acre system, which is fed from a creek, ran for 395 hours. The equipment and infrastructure for that pivot, including 1,800 feet of underground pipe, was quite expensive, but we still project a quick payoff.

“We had to build 25 bridges to accommodate the wheel tracking for one of the systems, and 15 for another. We make the bridges ourselves; we’re all pretty good welders.

“And we’re constantly installing pipes to facilitate drainage from our fields — it’s a never-ending process. But even though most of our land is in the river bottom, we almost never have any overflow. An exception was the year we got a 12-inch rain.”

More grain storage, new dryer

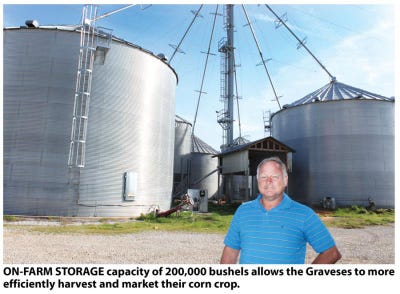

With the construction of a new 54,000 bushel bin last year, the Graveses have increased their on-farm grain storage capacity to 200,000 bushels.

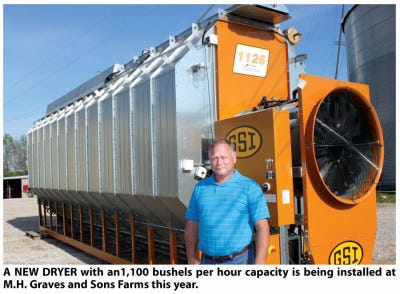

“We just bought a new natural gas-powered GSI dryer that will double corn drying capacity to 1,100 bushels per hour,” Mike says. “It’s not that expensive to dry corn — about 10 cents a bushel — and the added convenience is well worth it. Being able to dry at that volume, on our own schedule, lets us harvest two to three weeks earlier than we would otherwise.”

They were contracting their grain hauling, but he says, “That got to be very expensive, so now we do our own trucking. With the money saved in just one year, we were able to buy two new hopper bottom trailers and two used Peterbilt trucks. We also have half ownership of another truck in partnership with the Tippah County Co-op, and we have two tandem trucks to haul grain from the fields to our bins.”

And says Tyler, who had just returned from a 200-mile round trip with a load of poultry litter, “We are saving about $500 a load by using these trucks and trailers to haul litter.”

This is the third year they’ve used poultry litter in their fertility program, Mike says. “It’s very effective, and initially was considerably cheaper than commercial fertilizer. But there is so much competition for it now that the price differential has narrowed quite a bit and we can’t get all that we need. So, we will use some commercial fertilizer.

“Last year, we applied 1.5 tons per acre of poultry litter on our cotton and corn land. We fertilize according to soil test recommendations and we also get an analysis on the poultry litter. It usually runs about 60 units of nitrogen, and 60 each of potash and phosphate. Sometimes, we may have to add a little potash.

“You can tell to the row where we’ve applied poultry litter; the crop is greener, more lush. And you can see it on the yield monitors at harvest.”

They also bought a Caterpillar loader for use in moving the poultry litter and for other farm chores. “It has been a very useful piece of equipment,” Allen says. “We also picked up a used forklift for $1,500, and that was money well spent.”

Considering a new cotton picker

The Graveses are also considering buying a new John Deere cotton picker with the on-board module builder system.

“With the savings we’d realize from reducing equipment and labor, we figure it would pay for itself,” Mike says. “As things are now, we have to basically shut down our soybean operation while we’re harvesting cotton. The new picker would free up time we could spend on soybeans. We’d need new planters, but with that picker we could cut our cotton equipment from 10 pieces to four, with a significant reduction in labor. We think it would be a win-win situation — but we’ll have to watch what cotton prices do.”

They recently added a new John Deere 8320R tractor with GPS and auto-steer. Other equipment includes Deere 8400, 8410, 8420, 4750, and 4960 tractors; two 9770 combines; and three 9970 four-row cotton pickers.

“We have a John Deere 1790 40-foot planter,” Mike says. “All our corn is on 30-inch rows and soybeans on 15-inch rows. The planter has RowCommand, which prevents planting the same area twice. With seed at $250 a bag, that can represent quite a saving. We also have a Kinze planter.

“Our Deere 4720 sprayer has GPS/auto-steer and swath control, which eliminates any overlaps and double-spraying — another cost savings.

“We do all our minor equipment repairs and maintenance, but for anything major we get the John Deere mechanic to do it.”

Changes in equipment and production systems have enabled the Graveses to get more done in less time, he says. “We used to plant maybe 100 acres a day, going from sunup until sundown. Now, we can easily plant 300 to 400 acres a day.”

“All the equipment today is better and faster, with less downtime,” says Allen. “We hardly ever have to run at night, and we’re able to have more family time.”

They have a 90x170 foot equipment shed that houses most of their machinery, and another storage facility for seed, chemicals, and smaller equipment.

The Graveses have two full-time employees, Joey Holloway, who has been with them for 26 years, and Greg Grisham. They use some part-time help at busy times in the spring and fall.

This year’s cropping plans include about 2,000 acres of soybeans, 1,100 acres of cotton, and 1,100 acres of corn.

“ With cotton prices slipping, though, we could switch some acres out of that into corn or beans,” Mike says. “On our soils, we really can do better money-wise with corn than beans.”

“We planted some wheat last fall, the first we’ve had in years. We have about 400 acres on marginal land that came out of CRP. It’s really not good soybean ground, so we may just leave it idle after the wheat comes off. We rotate our corn and soybean land, and some of the cotton land, but we tend to have continuous cotton on fields that are best suited to it.

“We no-till everything, unless we rut up fields during harvest or we change crops and need to do some tillage. We like to come back and plant on the same beds.

“We hardly ever plant corn before late April or early May. We never get in a hurry on corn planting; three years ago, we planted into June and made 165 bushels, which was excellent for non-irrigated corn.”

They’ll plant mostly Pioneer corn varieties, Mike says — 1615, 1745, 2033, and on droughty hill land, 1184. “We’re also trying a new variety this year, 2088.

“For cotton, we plant primarily Deltapine 0922, a Roundup Ready Flex variety, which has been very good for us. We plant some Asgrow 4403 soybeans, but mostly Pioneer 94Y70 and 94Y20 — all Group IVs that we space out to facilitate harvest. We’ll start with the early 4s and end with the late 4s.”

Ownership in cotton gin

They have a one-fourth ownership in Farmers Gin at nearby Ashland, Miss., and gin their cotton there. “The gin processed 7,500 bales last year,” Mike says, “but back in ‘normal’ cotton years, it ginned as many as 23,000. At cotton’s low point, though, it did only 1,400 bales.”

Their cotton is marketed through Lee Thompson at Marks, Miss., and corn is sold through a Cargill marketing service. “They give us market updates every day via cell phone and the Internet. It takes a lot of the guesswork out of selling that crop. Our soybeans are hauled to a terminal at Memphis.”

Thanks to technology, insects and weeds are not a major problem, Mike says.

“We haven’t had any resistant pigweed yet, though it’s all around us. We do have some resistant marestail. We change up chemistries to do what we can to avoid resistance issues. We changed our burndown this year and are using a new DuPont product, LeadOff, along with Roundup and 2,4-D.

“We haven’t sprayed for worms since 1995, a year when they almost ruined us. Bt technology has pretty much solved that problem. We normally spray once for plant bugs and once for stink bugs.

“We use a fungicide on all our soybeans and a lot of times we’ll use one on corn, too.”

A pest that is a problem, Allen says, is deer. “There are some fields where we can’t grow soybeans because of them, and now they’re beginning to get a taste for corn, too. We probably lose 100 acres of soybeans to deer every year.”

Mike says they would consider expanding if more acres came along. About half the land they now farm is owned, the other half rented.

“We’ve been at this level for several years,” he says, “except for the land we have in wheat this year that came out of CRP. There just isn’t that much land that becomes available in this area.”

About the Author(s)

You May Also Like